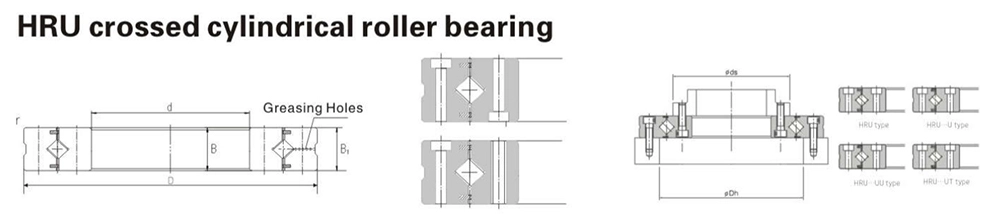

Crossed Roller Bearing

The dimension of the inner and outer rings is a minimum to miniaturization, especially extremely thin type is close to the limit of small size, and high rigidity, so it is optimal for applications such as joints and swiveling units of industrial robots, swiveling tables of machining centers, rotary units of manipulators, precision rotary tables, medical instrument, measuring instruments, IC manufacturing machines, and etc..

Crossed Roller Bearing: The Precision Solution for Demanding Applications

A crossed roller bearing is a sophisticated type of bearing designed to provide high precision and rigidity in various applications. Unlike traditional roller bearings, its use cylindrical rollers arranged in a crisscross pattern. This unique design allows them to handle both radial and axial loads simultaneously with minimal friction and high accuracy. Ideal for demanding environments, these bearings are crucial in industries where precision and reliability are paramount.

CHG Bearing: Your Expert Partner in Crossed Roller Bearings

At CHG Bearing, we specialize in providing top-quality products tailored to your specific needs. Here’s why you should choose us:

- Customization and Solutions: We offer bespoke solutions to meet the unique requirements of different working conditions, ensuring optimal performance for your applications.

- 30 Years of Industry Experience: With three decades in the industry, we have developed deep expertise and have collaborated with numerous large companies.

- Innovative and Certified: Our company holds over 50 invention patents and is certified under ISO9001 for quality management and ISO14001 for environmental management, ensuring you receive high-quality Crossed Roller Bearing, reliable products.

Technical Specifications

| Specification | Details |

|---|---|

| Inner Diameter | Customizable |

| Outer Diameter | Customizable |

| Width | Customizable |

| Load Capacity | High radial and axial load capacity |

| Material | GCr15 or custom materials |

| Temperature Range | Suitable for extreme temperatures |

| Certifications | ISO9001, ISO14001 |

Benefits of Crossed Roller Bearings

- High Precision: With their precise alignment and low friction, products ensure exceptional accuracy and smooth operation.

- High Load Capacity: Capable of handling both radial and axial loads, these bearings provide robust support in high-load situations.

- Excellent Rigidity: The design of crossed roller bearings enhances rigidity, which is crucial for maintaining stability and extending the lifespan of machinery.

- Versatility: Suitable for various applications, from aerospace to medical equipment, ensuring adaptability across industries.

Applications

Products are essential in several fields, including:

- Aerospace: Critical for the motion mechanisms of aircraft landing gear, missiles, drones, and other high-speed, high-load applications.

- Robotics: Used in robot arms, chassis, and motion joints for precise and reliable movement.

- Machine Tools: Key components in spindle transmission devices and feed systems for high-precision machining.

- Medical Equipment: Employed in CT machines and MRI machines to provide stable operation under demanding conditions.

- Automobile Manufacturing: Integral in steering gears, transmissions, and suspension systems for reliable vehicle performance.

- Semiconductor and LCD Manufacturing: Utilized in handling robots and inspection platforms for high-precision control.

Installation Guide

- Preparation: Ensure the installation area is clean and free from contaminants.

- Alignment: Carefully align the bearing to avoid misalignment and ensure optimal performance.

- Mounting: Secure the bearing in place using appropriate tools and techniques, following manufacturer guidelines.

- Lubrication: Apply the recommended lubricant to reduce friction and wear.

Maintenance and Care

- Regular Inspection: Check for signs of wear, damage, or contamination.

- Lubrication: Maintain proper lubrication to ensure smooth operation and extend bearing life.

- Cleanliness: Keep the bearing and its housing clean to prevent premature failure.

FAQ

Q: What is the load capacity of products? A: Crossed roller bearings are designed to handle high radial and axial loads. Specific load capacities depend on the bearing size and application.

Q: Can products be used in extreme temperatures? A: Yes, they can operate in a wide range of temperatures, making them suitable for harsh environments.

Q: How do I choose the right product for my application? A: Consider factors such as load capacity, size, and working environment. Consult with a bearing expert if needed.

Q: Are there any specific maintenance requirements for its? A: Regular inspection, proper lubrication, and cleanliness are key to maintaining their performance.

Customer Reviews

"CHG Bearing's products have significantly improved the performance of our robotics systems. Their precision and reliability are unmatched." – Robotics Engineer

"We've relied on CHG Bearing for years for our aerospace applications. Their products never disappoint in terms of quality and durability." – Aerospace Manufacturer

Contact Us

For detailed information on our crossed roller bearings or to request a quote, please reach out to us at sale@chg-bearing.com. Our team is ready to assist you with your specific needs and provide the best solutions for your applications.