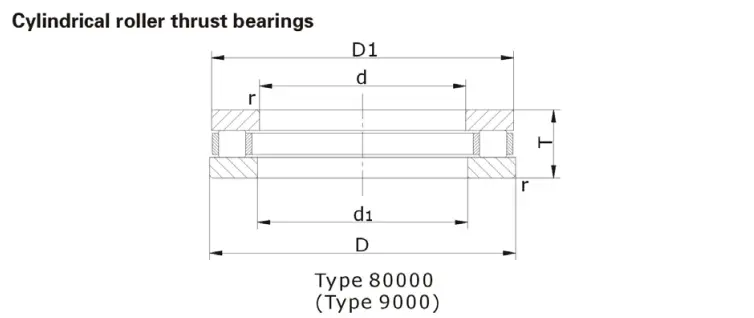

Cylindrical Roller Thrust Bearings

screw-down-bearings

2. Sizes: Inner Diameter; 200-380mm

Outer Diameter: 400-670mm Weight: 75-274kg

3. Feature:Cylindrical roller thrust bearings are separable. They only carry axial loads in one direction and slight shock loads, but their loading capacity is much higher than thrust ball bearings with same dimensions. They can limit axial displacement of shafts or housing in one direction, so can be as axial locating bearings in one direction. the slippage will formed on the raceways because of the linear velocity differences of two ends of rollers while rolling. So the Limiting speed of these bearings is lower than thrust ball bearings, and they are usually applied to low speed applications.

Tapered roller thrust bearings can only carry axial loads and limit axial displacement in one direction, so they can be used as axial locating bearings in one direction. Comparing with cylindrical roller thrust bearings, their loading capacity is higher, relative slippage and limiting speed are lower.

4. Cage: Metal machined solid cages are used for cylindrical roller thrust bearings which are standard design, but otehr cages also can be provided according to customers.

Steel or brass cages are used in tapered roller thrust bearings

5. Application:Cylindrical roller thrust bearings mainly used in heavy machine tools, large power gear boxed for ships, oil rigs, vertical machines, etc.

Tapered roller thrust bearing are widely used in construction machinery, automotives, generating equipments, etc.

6. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

What is a Cylindrical Roller Thrust Bearing?

Cylindrical Roller Thrust Bearings are designed to handle high axial loads while offering high precision and durability. Unlike other bearings, these are specifically engineered to support loads in one direction, making them ideal for applications with significant thrust forces. The design incorporates cylindrical rollers that run parallel to the axis of the bearing, which helps distribute the load evenly and minimizes friction.

CHG Bearing: Your Trusted Partner for Cylindrical Roller Thrust Bearings

CHG Bearing stands out as a leading manufacturer and supplier of products. With over 30 years of industry experience, CHG Bearing is dedicated to providing high-quality, customizable solutions for diverse working conditions. We have established partnerships with numerous large corporations and hold over 50 invention patents, showcasing our innovation and expertise. Our products meet rigorous standards, evidenced by our ISO9001 quality management system, ISO14001 environmental management system, and other certifications.

For more information or to discuss your specific requirements, contact us at sale@chg-bearing.com.

Technical Specifications

| Specification | Details |

|---|---|

| Type | Cylindrical Roller Thrust Bearing |

| Material | High-quality steel, custom materials available |

| Load Capacity | High axial load capacity |

| Precision | High precision for smooth operation |

| Temperature Range | Up to 200°C (custom options available) |

| Certifications | ISO9001, ISO14001, others |

Benefits of Cylindrical Roller Thrust Bearings

- High Load Capacity: These bearings are designed to support substantial axial loads, ensuring reliable performance even under heavy-duty conditions.

- Durability and Longevity: Built to withstand harsh environments, they offer extended service life and reduced maintenance needs.

- Low Friction: The design minimizes friction between rolling elements, resulting in smoother operation and increased efficiency.

- Customization: Tailored solutions to meet specific requirements, including size, material, and lubrication methods.

Applications

Cylindrical Roller Thrust Bearings are versatile components used across various industries:

- Metallurgical Industry: Essential in large rotating equipment such as blast furnaces, rolling mills, and steelmaking machinery.

- Mining Machinery: Ideal for equipment like jaw crushers, impact crushers, and vibrating screens where high load capacity and reliability are crucial.

- Heavy Machinery: Suitable for applications involving significant thrust forces and demanding operational conditions.

Installation Guide

Proper installation of products is critical to ensure optimal performance. Follow these steps:

- Preparation: Clean all components and ensure the mounting surfaces are smooth.

- Alignment: Align the bearing correctly with the shaft and housing to avoid uneven loading.

- Assembly: Carefully place the bearing into position, ensuring it is seated properly.

- Lubrication: Apply the appropriate lubricant as specified to ensure smooth operation and longevity.

- Testing: After installation, test the equipment to confirm proper function and alignment.

Maintenance and Care

To maximize the lifespan of your Cylindrical Roller Thrust Bearings, adhere to the following maintenance practices:

- Regular Inspections: Check for signs of wear, damage, or misalignment.

- Lubrication: Maintain proper lubrication levels and replace lubricants as needed.

- Cleaning: Keep the bearings and surrounding areas clean to prevent contamination.

- Monitoring: Track performance and address any issues promptly to avoid potential failures.

FAQ

Q: What is the main advantage of this bearings over other types?

A: The main advantage is their ability to handle high axial loads with minimal friction, making them ideal for applications requiring substantial thrust support.

Q: Can these bearings be customized?

A: Yes, CHG Bearing offers customization options for size, material, and lubrication methods to meet specific operational needs.

Q: What is the typical lifespan of Cylindrical Roller Thrust Bearings?

A: The lifespan depends on factors like load, operating conditions, and maintenance. Proper care can significantly extend their service life.

Q: How do I choose the right bearing for my application?

A: Consider factors such as load capacity, operating environment, and specific requirements. Consulting with a bearing expert can help ensure you select the optimal product.

Customer Reviews

"CHG Bearing provided excellent support and high-quality bearings for our heavy machinery. Their expertise and quick response were invaluable." — John D., Production Manager

"We've been using CHG Bearings for several years and have always been impressed with their product reliability and customer service." — Emily R., Purchasing Manager

Contact Us

For more details or to request a quote, please contact us at:

- Email: sale@chg-bearing.com

At CHG Bearing, we are committed to delivering top-quality Cylindrical Roller Thrust Bearings tailored to your specific needs. Reach out today to learn how we can support your operational requirements.

YOU MAY LIKE

VIEW MOREDouble Row Cylindrical Roller Bearing

VIEW MOREDouble Row Cylindrical Roller Bearing VIEW MORESealed Tapered Roller Bearing

VIEW MORESealed Tapered Roller Bearing VIEW MORECylindrical Roller Thrust Bearing

VIEW MORECylindrical Roller Thrust Bearing VIEW MOREAxial Radial Cylindrical Roller Bearings

VIEW MOREAxial Radial Cylindrical Roller Bearings VIEW MOREDouble Row Spherical Roller Bearing

VIEW MOREDouble Row Spherical Roller Bearing VIEW MORESelf Aligning Tapered Roller Bearing

VIEW MORESelf Aligning Tapered Roller Bearing VIEW MORESealed Spherical Roller Bearings

VIEW MORESealed Spherical Roller Bearings VIEW MORELarge Tapered Roller Bearings

VIEW MORELarge Tapered Roller Bearings