Roll Neck Bearings

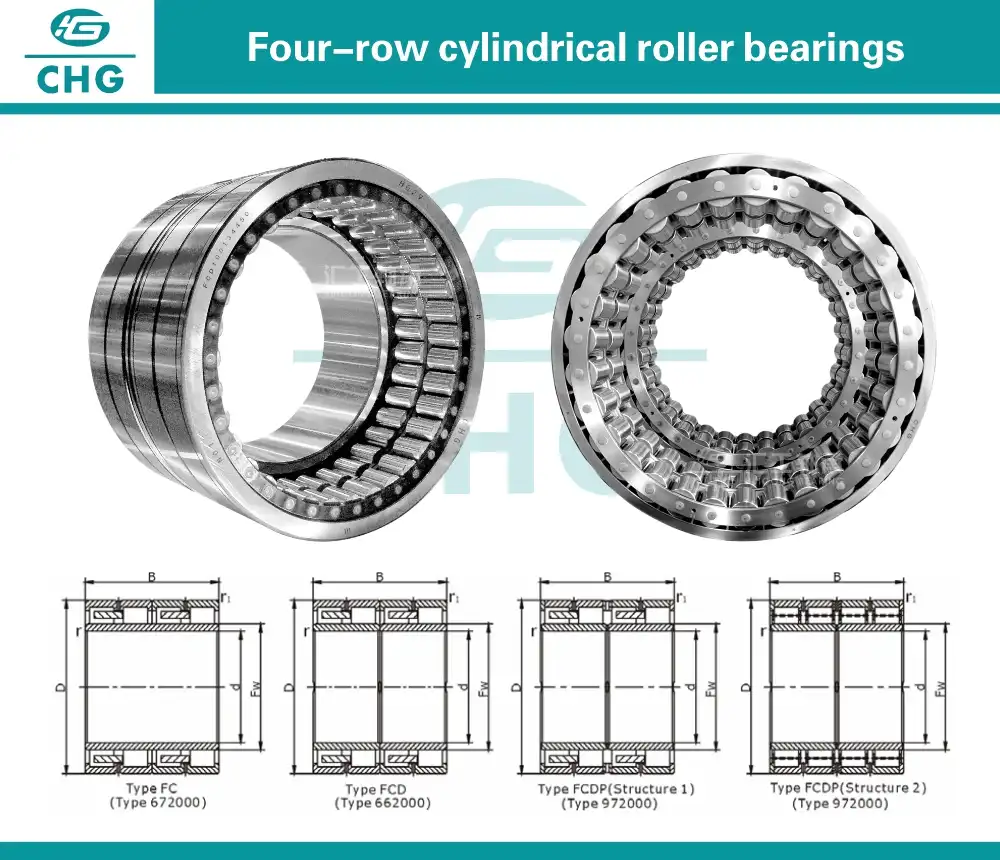

Bearing Types: single / double/ four row cylindrical roller bearings, single / double/ four row tapered roller bearings, full complement cylindrical roller bearings, backing up bearing and many kinds of bearings with different structures.

Application Fields: wire & bar mill, hot strip mills, cold strip mills, section mill,sendzimir mill, continuous casting machine supporting bearing and mill machine and fields of bearing block for rolling mill.

Manufacture Capacity: Can provide 400 kinds of bearing specifications and 30,00 sets of bearings to customer.

What are Roll Neck Bearings?

Roll Neck Bearings are specialized bearings used in the metallurgical industry, particularly in rolling mills and other large rotating equipment like blast furnaces and steelmaking machinery. These bearings are designed to support heavy loads, enable smooth rotation, and withstand harsh operating conditions, ensuring the reliability and efficiency of your equipment.

Why Choose CHG Bearing for Your Roll Neck Bearings?

CHG Bearing is a leading manufacturer and supplier of Roll Neck Bearings, offering customized solutions tailored to your specific working conditions. With over 30 years of industry experience, we have partnered with numerous large companies, providing high-quality bearings that meet the demanding requirements of the metallurgical and mining industries.

Our company holds more than 50 invention patents and has passed ISO9001 quality management system, ISO14001 environmental management system, and other certifications. We pride ourselves on our ability to deliver reliable, high-precision bearings that ensure the smooth operation of your equipment.

Feel free to contact us at sale@chg-bearing.com for any inquiries or to discuss your specific needs.

Technical Specifications

| Specification | Details |

|---|---|

| Bearing Type | Roll Neck Bearings |

| Material | chrome steel / carburised steel |

| Load Capacity | High-load capacity for heavy industrial equipment |

| Temperature Range | -20°C to +120°C |

| Lubrication | Grease, oil, or custom lubrication systems |

| Precision Level | P0/P6/P5/P4/P2 |

| Certification | ISO9001, ISO14001, Third party testing certificate is available |

Benefits of Using CHG Roll Neck Bearings

- High Precision and Quality: Our product are engineered to provide high precision and rigidity, ensuring stable and smooth operation of your equipment.

- Long Life and Wear Resistance: Designed to withstand the harshest environments, our bearings offer extended service life, reducing maintenance costs and downtime.

- Customization: We offer tailored solutions to meet the specific requirements of your equipment, from material selection to lubrication methods.

- Quick Response and Delivery: We understand the importance of minimizing downtime in your operations. Our efficient supply chain ensures fast delivery, even for custom orders.

- Cost-Effectiveness: We offer high-quality bearings at competitive prices, delivering exceptional value without compromising on performance.

Applications of Roll Neck Bearings

Roll Neck Bearings are integral to the smooth operation of various heavy-duty industrial equipment, including:

- Rolling Mills: Essential for supporting the rolls in rolling mills, ensuring efficient metal processing.

- Blast Furnaces: Used in the rotation of furnace components, aiding in the consistent production of metal.

- Mining Machinery: Key components in crushers, vibrating screens, and feeders, providing reliable performance in harsh conditions.

- Steelmaking Equipment: Ensures the smooth operation of machinery involved in the steel production process.

Installation Guide

Proper installation is crucial for the optimal performance of Roll Neck Bearings. Follow these steps for a successful installation:

- Preparation: Ensure the bearing housing and shafts are clean and free from contaminants.

- Alignment: Carefully align the bearing with the shaft to prevent misalignment and uneven wear.

- Lubrication: Apply the appropriate lubricant as specified in the technical documentation.

- Assembly: Gently slide the bearing into place, avoiding excessive force to prevent damage.

- Inspection: Once installed, inspect the bearing for any signs of misalignment or improper installation.

Maintenance and Care

To maximize the lifespan and performance of your product, regular maintenance is essential:

- Routine Inspections: Check for signs of wear, corrosion, or misalignment.

- Lubrication: Reapply lubricant according to the operating conditions and manufacturer’s recommendations.

- Cleaning: Keep the bearing and surrounding area free from dust and debris.

- Replacement: Replace worn or damaged bearings promptly to avoid equipment failure.

Frequently Asked Questions (FAQs)

Q1: What materials are used in CHG Roll Neck Bearings?

A1: Our bearings are made from high-grade steel and customized alloys, designed to withstand heavy loads and harsh environments.

Q2: Can you customize Roll Neck Bearings for specific applications?

A2: Yes, we offer customization in terms of size, structure, material, and lubrication to meet your specific needs.

Q3: How long do Roll Neck Bearings last?

A3: The lifespan of our bearings varies depending on the operating conditions, but they are designed for long-term durability and reliability.

Q4: What is the lead time for custom Roll Neck Bearings?

A4: Lead times vary depending on the complexity of the customization, but we strive to deliver as quickly as possible to meet your needs.

Q5: How do I know if my bearing needs replacement?

A5: Signs of wear, increased noise, or vibration are indicators that a bearing may need replacement.

Customer Reviews

John S., Production Manager at XYZ Metals

"CHG Bearing's product have significantly reduced our maintenance downtime. Their high precision and durability are unmatched."

Emily R., Technical Engineer at ABC Mining

"The customization options provided by CHG Bearing allowed us to find the perfect solution for our unique equipment requirements. Highly recommend!"

Contact Us

Ready to enhance your equipment with high-quality Roll Neck Bearings? Contact us today at sale@chg-bearing.com to discuss your needs and get a custom quote.

This product page is designed to offer valuable insights to purchasing managers, technical engineers, and production managers, addressing their specific needs while adhering to SEO best practices for maximum visibility.