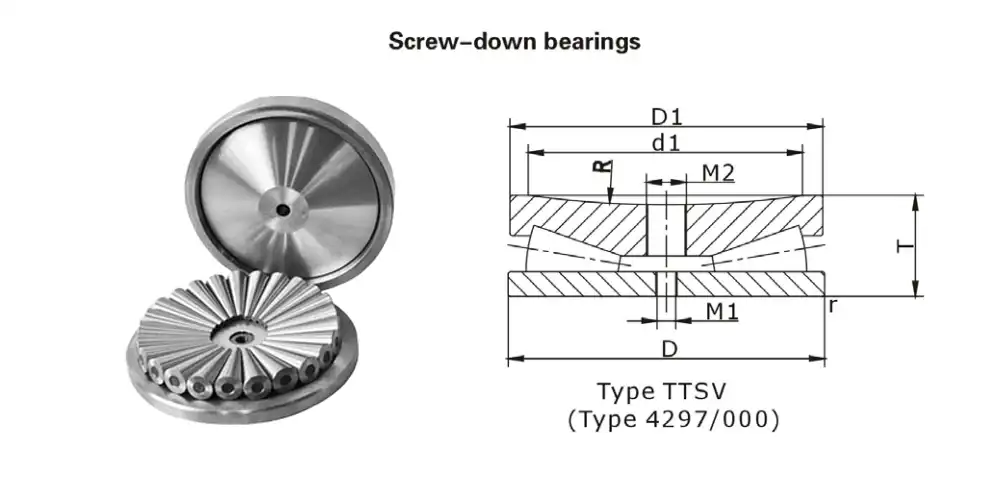

What are Screw Down Bearings?

Screw down bearings are specialized rolling-element bearings engineered to handle extreme loads and harsh conditions. These bearings are particularly vital in industries such as metallurgy and mining, where they support large rotating equipment like blast furnaces, rolling mills, and steelmaking machinery. Their robust design ensures that they can bear axial and radial loads efficiently while maintaining excellent operational stability.

CHG Bearing: Your Trusted Manufacturer

Here's why you should choose us:

Customization and Solutions: We offer tailored solutions to meet various working conditions, ensuring that our products fit seamlessly into your equipment.

30 Years of Industry Experience: Our expertise is backed by decades of serving large companies with reliable bearing solutions.

Innovation and Certifications: With over 50 invention patents, we have passed ISO9001 quality management and ISO14001 environmental management certifications. Feel free to contact us at [sale@chg-bearing.com] for more information.

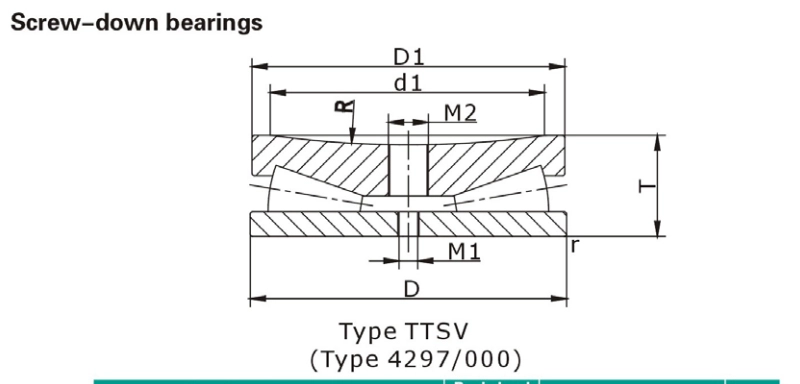

Technical Specifications

| Specification | Details |

|---|---|

| Load Capacity | Extremely high |

| Material | Chrome steel/G20Cr2Ni4A |

| Temperature Range | -40°C to +200°C |

| Customization Options | Size, structure, material, lubrication |

| Standards Compliance | ISO9001, ISO14001 |

Benefits of Screw Down Bearings

High Precision and Quality: Essential for ensuring the operational stability and processing quality of machinery in demanding environments.

Durability and Wear Resistance: Built to withstand high temperatures, heavy loads, and other challenging conditions, minimizing maintenance needs and maximizing uptime.

Customizability: Adaptable to diverse applications through customizable sizes, structures, and materials.

Cost-effectiveness: Offers superior performance and longevity at a competitive price point, delivering outstanding value to customers.

Applications

Screw down bearings play a critical role in multiple sectors:

Metallurgical Industry: Ideal for blast furnaces, rolling mills, and steelmaking equipment due to their ability to handle extreme pressures and temperatures.

Mining Machinery: Integral in jaw crushers, impact crushers, vibrating screens, and feeders, providing strength and alignment even in high-impact scenarios.

Installation Guide

Preparation: Ensure all components are clean and tools are ready.

Alignment: Properly align bearings to prevent misalignment issues.

Lubrication: Use appropriate lubricants to reduce friction and wear.

Mounting: Employ precision techniques to secure bearings in place effectively.

Maintenance and Care

Routine Inspections: Regularly check bearings for signs of wear and replace them as needed.

Consistent Lubrication: Maintain optimal lubrication levels to ensure smooth operation.

Environmental Control: Protect bearings from contaminants to extend their lifespan.

FAQ

Q: What makes screw down bearings different from standard bearings?

A:They are designed to handle higher loads and more severe conditions than standard bearings, making them suitable for heavy-duty industrial applications.

Q: Can these bearings be customized for specific equipment?

A: Yes, we offer customization in terms of size, structure, material, and lubrication to meet your precise requirements.

Customer Reviews

"CHG Bearing has transformed our production line, reducing downtime significantly."

— Michael T., Production Manager

"The durability and precision of CHG's bearings are unmatched. We've seen improved operational stability since using them."

— Emily R., Technical Engineer

Contact Us

For expert advice and custom solutions on screw down bearings, please contact us at [sale@chg-bearing.com]. Our team is dedicated to helping you achieve efficient and reliable operations.

| Boundary dimensions | Basic load ratings | Designations | Mass | ||||||||

| mm | kN | Current | Original | kg | |||||||

| D | D1 | d1 | T | R | M1 | M2 | rmin | Coa | |||

| 150 | 148 | 127 | 48 | 228.6 | M12 | - | 1.5 | 1630 | TTSV150 | 4297/150 | 5 |

| 175 | 173 | 152 | 53 | 228.6 | M12 | - | 1.5 | 2180 | TTSV175 | 4297/175 | 8 |

| 203 | 201 | 178 | 65 | 254 | M12 | - | 1.5 | 2540 | TTSV203 | 4297/203 | 11 |

| 205 | 203 | 178 | 65 | 254 | M20 | - | 1.5 | 3370 | TTSV205 | 4297/205 | 15 |

| 235 | 233 | 208 | 73 | 280 | M20 | - | 1.5 | 3370 | TTSV235 | 4297/235 | 18 |

| 265 | 263 | 229 | 81 | 304.8 | M20 | - | 1.5 | 4130 | TTSV265 | 4297/265 | 24 |

| 320 | 318 | 280 | 95 | 380 | M24 | - | 1.5 | 7370 | TTSV320 | 4297/320 | 42 |

| 377 | 375 | 330 | 112 | 457.2 | M24 | - | 2.5 | 8230 | TTSV377 | 4297/377 | 86 |

| 380 | 378 | 330 | 112 | 457.2 | M24 | M30 | 1.5 | 8220 | TTSV380 | 4297/380 | 67 |

| 410 | 408 | 355 | 122 | 508 | M24 | M30 | 3 | 11300 | TTSV410 | 4297/410 | 115 |

| 440 | 438 | 380 | 130 | 508 | M24 | M36 | 3 | 18500 | TTSV440 | 4297/440 | 140 |

| 495 | 492 | 432 | 146 | 558.8 | M24 | M36 | 3 | 19100 | TTSV495 | 4297/495 | 198 |

| 525 | 522 | 460 | 155 | 635 | M24 | M36 | 3 | 20380 | TTSV525 | 4297/525 | 210 |

| 555 | 552 | 482 | 165 | 635 | M24 | M36 | 3 | 21380 | TTSV555 | 4297/555 | 275 |

| 580 | 577 | 510 | 165 | 710 | M24 | M42 | 3 | 23540 | TTSV580 | 4297/580 | 250 |

| 610 | 607 | 533 | 178 | 762 | M30 | M42 | 3 | 24170 | TTSV610 | 4297/610 | 350 |

| 640 | 637 | 550 | 185 | 762 | M30 | M42 | 3 | 28670 | TTSV640 | 4297/640 | 410 |

| Boundary dimensions | Basic load ratings | Designations | Mass | ||||||||

| mm | kN | Current | Original | kg | |||||||

| D | D1 | d1 | T | R | M1 | M2 | rmin | Coa | |||

| 150 | 148 | 127 | 55 | 457.2 | M12 | - | 1.5 | 1630 | TTSX150 | 4379/150 | 7 |

| 175 | 173 | 152 | 62 | 457 | M12 | - | 1.5 | 2180 | TTSX175 | 4379/175 | 11 |

| 205 | 203 | 178 | 76 | 508 | M20 | - | 1.5 | 2540 | TTSX205 | 4379/205 | 18 |

| 235 | 233 | 208 | 85 | 560 | M20 | - | 1.5 | 3370 | TTSX235 | 4379/235 | 26 |

| 265 | 263 | 229 | 95 | 609.6 | M20 | - | 1.5 | 4130 | TTSX265 | 4379/265 | 37 |

| 320 | 318 | 280 | 112 | 762 | M20 | - | 2.5 | 7370 | TTSX320 | 4379/320 | 62 |

| 380 | 378 | 330 | 129 | 914.4 | M24 | M30 | 1.5 | 8550 | TTSX380 | 4379/380 | 101 |

| 410 | 408 | 355 | 142 | 1016 | M24 | M30 | 3 | 11300 | TTSX410 | 4379/410 | 130 |

| 440 | 438 | 380 | 152 | 1016 | M24 | M36 | 3 | 18500 | TTSX440 | 4379/440 | 160 |

| 495 | 492 | 432 | 172 | 1066.8 | M24 | M36 | 3 | 19100 | TTSX495 | 4379/495 | 210 |

| 525 | 522 | 460 | 180 | 1270 | M24 | M36 | 3 | 20380 | TTSX525 | 4379/525 | 250 |

| 555 | 552 | 482 | 192 | 1270 | M24 | M36 | 3 | 21380 | TTSX555 | 4379/555 | 280 |

| 580 | 577 | 510 | 195 | 1422.4 | M24 | M36 | 3 | 21540 | TTSX580 | 4379/580 | 310 |

| 610 | 607 | 533 | 205 | 1520 | M30 | M42 | 3 | 24170 | TTSX610 | 4379/610 | 410 |

| 640 | 637 | 550 | 214.8 | 1740 | M30 | M42 | 3 | 28670 | TTSX640 | 4379/640 | 450 |

| 710 | 705 | 610 | 250 | 1600 | M30 | M42 | 4 | 31540 | TTSX710 | 4379/710 | 850 |

| 750 | 745 | 650 | 260 | 1600 | M30 | M48 | 4 | 38430 | TTSX750 | 4379/750 | 750 |

| 800 | 795 | 700 | 270 | 1700 | M30 | M48 | 5 | 40150 | TTSX800 | 4379/800 | 930 |