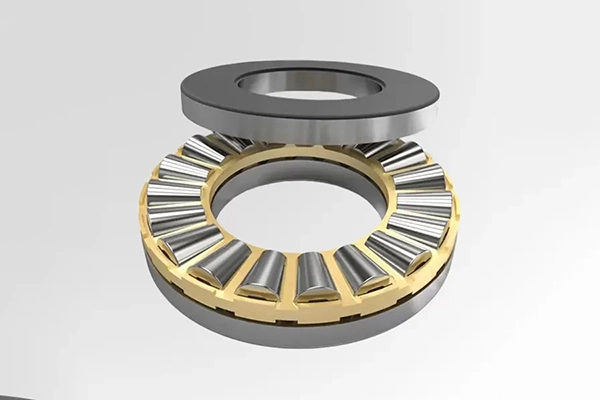

Taper Roller Thrust Bearings

Outer Diameter: 400-670mm

Weight: 75-274kg

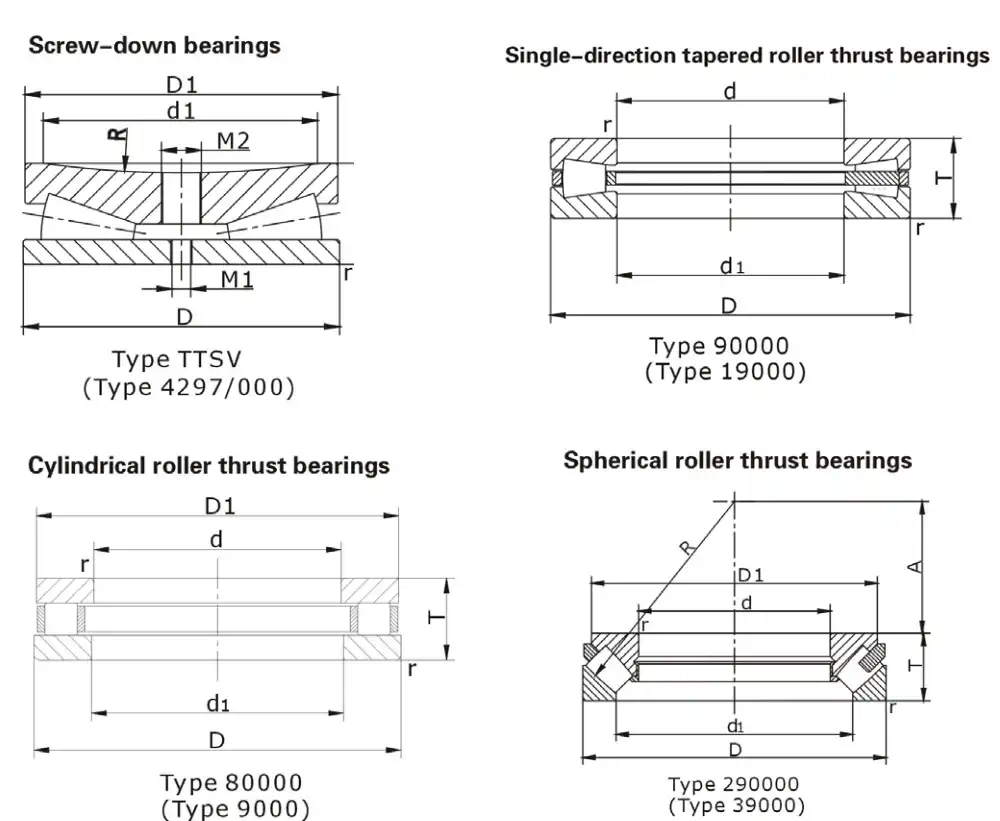

Tapered roller thrust bearings can only carry axial loads and limit axial displace-

ment in one direction, so they can be used as axial locating bearings in one

direction.Comparing with cylindrical roller thrust bearings, their loading capacity is

higher, relative slippage and limiting speed are lower.

Steel or brass solid cages are used in tapered roller thrust bearings.

Tapered roller thrust bearings are widely used in construction

machinery,automotives, generating equipment,etc.

What are Taper Roller Thrust Bearings?

Taper Roller Thrust Bearings are a type of bearing designed to handle axial loads and moderate radial loads. Unlike other bearing types, these bearings are uniquely engineered with tapered rolling elements, which help in distributing the load more effectively. This design allows them to manage higher thrust loads and ensure smooth operation in various machinery applications.

These bearings are essential for applications where heavy axial loads are present, and they offer a combination of durability and reliability. With their distinctive design, taper roller thrust bearings excel in performance and longevity, making them a popular choice in industries like metallurgy and mining.

CHG Bearing: Your Trusted Partner for Taper Roller Thrust Bearings

At CHG Bearing, we specialize in manufacturing high-quality tailored to meet diverse operational needs. Here’s why you should choose us:

- Customization and Solutions: We provide bespoke solutions for different working conditions, ensuring optimal performance and longevity of your bearings.

- Industry Experience: With over 30 years in the industry, our expertise is backed by collaborations with numerous large-scale companies.

- Innovative Edge: We hold more than 50 invention patents and are certified under ISO9001 for quality management and ISO14001 for environmental management.

Our commitment to quality and innovation ensures that our Taper Roller Thrust Bearings meet the highest standards.

For customized solutions and inquiries, feel free to contact us at sale@chg-bearing.com.

Technical Specifications

| Feature | Specification |

|---|---|

| Bearing Type | Taper Roller Thrust Bearing |

| Load Capacity | High axial load capacity |

| Design | Tapered rolling elements |

| Material | High-grade steel and alloys |

| Certification | ISO9001, ISO14001 |

| Customization Options | Size, structure, and lubrication |

| Applications | Metallurgy, mining, and machinery |

Taper Roller Thrust Bearings and Their Benefits

It offer several benefits:

- High Load Capacity: Designed to handle substantial axial loads, making them ideal for heavy-duty applications.

- Durability: With a robust construction, these bearings can withstand harsh operating conditions.

- Efficiency: They ensure smooth operation by reducing friction and wear in machinery.

- Longevity: High-quality materials and precision engineering contribute to a longer service life.

Applications

Taper Roller Thrust Bearings are used in various industries, including:

- Metallurgy: For blast furnaces, rolling mills, and steelmaking equipment.

- Mining: In jaw crushers, impact crushers, and vibrating screens.

- Machinery: Applied in diverse machinery where high axial loads are present.

Installation Guide

- Preparation: Ensure the bearing and shaft are clean and free of contaminants.

- Alignment: Align the bearing accurately with the housing to prevent misalignment issues.

- Assembly: Carefully place the bearing into the housing and press it into position without applying excessive force.

- Lubrication: Apply the recommended lubricant to the bearing for smooth operation.

Maintenance and Care

Proper maintenance extends the lifespan of your products:

- Regular Inspection: Check for signs of wear and tear, and ensure proper lubrication levels.

- Cleaning: Keep the bearings clean from contaminants and debris.

- Lubrication: Reapply lubrication as per manufacturer recommendations.

- Monitoring: Regularly monitor performance to identify any potential issues early.

FAQ

Q: What are the signs of a failing Taper Roller Thrust Bearing?

A: Common signs include unusual noise, vibration, and overheating. Regular maintenance can help identify issues before they become serious.

Q: Can Taper Roller Thrust Bearings be customized?

A: Yes, we offer customization options for size, structure, and lubrication methods to meet specific requirements.

Q: How often should Taper Roller Thrust Bearings be replaced?

A: The replacement frequency depends on usage and maintenance. Regular inspections can help determine the optimal replacement interval.

Q: What industries use Taper Roller Thrust Bearings?

A: They are widely used in metallurgy, mining, and various machinery applications that require handling of high axial loads.

Customer Reviews

John D. - "CHG Bearing's product have significantly improved the performance of our equipment. Their custom solutions are top-notch!"

Sarah L. - "The quality and durability of CHG's bearings are unmatched. We've seen a noticeable reduction in maintenance costs."

Michael T. - "Excellent customer service and fast delivery. The bearings meet our high standards and are reliable."

Contact Us

For more information about our Taper Roller Thrust Bearings or to request a quote, please contact us at:

Email: sale@chg-bearing.com