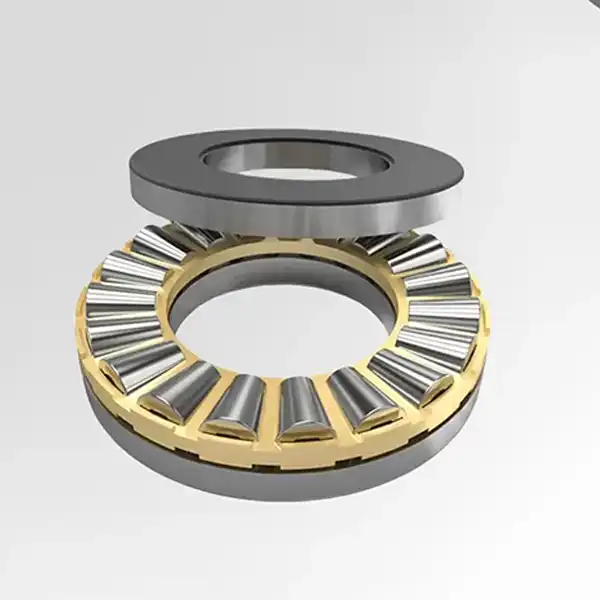

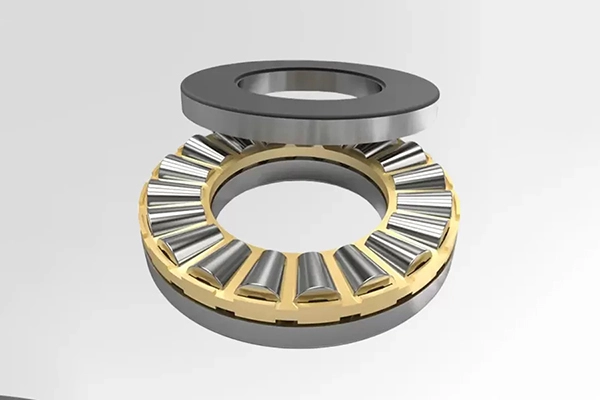

Tapered Roller Thrust Bearing

Outer Diameter: 400-670mm

Weight: 75-274kg

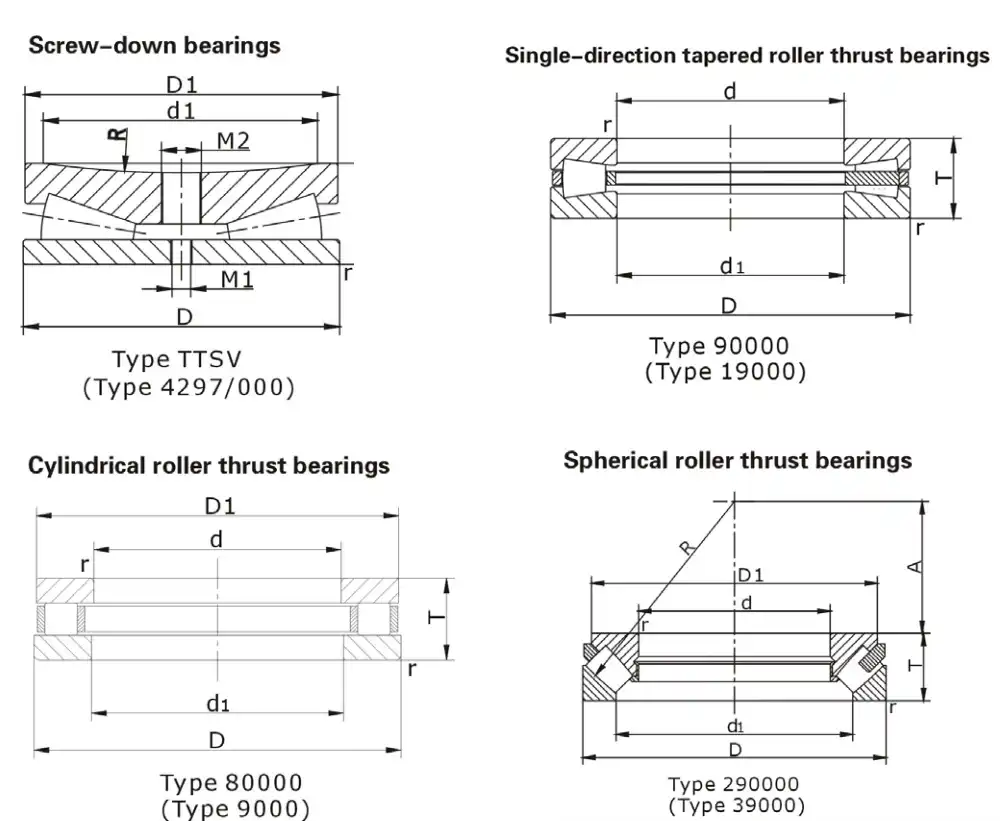

Tapered roller thrust bearings can only carry axial loads and limit axial displace-

ment in one direction, so they can be used as axial locating bearings in one

direction.Comparing with cylindrical roller thrust bearings, their loading capacity is

higher, relative slippage and limiting speed are lower.

Steel or brass solid cages are used in tapered roller thrust bearings.

Tapered roller thrust bearings are widely used in construction

machinery,automotives, generating equipment,etc.

What is a Tapered Roller Thrust Bearing?

A Tapered Roller Thrust Bearing is a specialized bearing designed to handle high axial loads and accommodate thrust forces. Unlike standard bearings, these are equipped with tapered rollers arranged in a specific angle to provide exceptional load-carrying capacity and precision. This unique design allows them to manage the heavy loads typically encountered in industries such as metallurgy and mining, where equipment must withstand extreme conditions.

CHG Bearing: Your Trusted Tapered Roller Thrust Bearing Manufacturer

At CHG Bearing, we pride ourselves on being a leading manufacturer and supplier of Tapered Roller Thrust Bearings. With over 30 years of experience in the industry, we have built a reputation for delivering high-quality, customized solutions tailored to various operational needs. Our extensive collaboration with major companies underscores our commitment to excellence and innovation.

Why Choose CHG Bearing?

Customization and Solutions: We offer tailored bearing solutions for diverse working conditions. Whether you need bearings for high-temperature environments or specific load requirements, we have the expertise to meet your needs.

Industry Experience: With three decades in the industry, our experience and knowledge ensure that you receive reliable and effective bearing solutions.

Innovative Capabilities: Our portfolio includes more than 50 invention patents, reflecting our commitment to technological advancement and continuous improvement.

Certifications: We adhere to international standards with certifications such as ISO9001 for quality management and ISO14001 for environmental management, ensuring that our products meet the highest quality and safety standards.

For more information or to discuss your specific requirements, feel free to contact us at sale@chg-bearing.com.

Technical Specifications

| Specification | Details |

|---|---|

| Bearing Type | Tapered Roller Thrust Bearing |

| Load Capacity | High axial load capacity |

| Material | GCr15/G20Cr2Ni4A |

| Operating Temperature | Up to 150°C (302°F) |

| Precision Rating | P0, P6, P5, P4 (customizable) |

| Lubrication | Grease or oil lubrication options |

Tapered Roller Thrust Bearing and Its Benefits

Enhanced Load Capacity

Tapered Roller Thrust Bearings are designed to handle significant axial loads. This is particularly valuable in applications where heavy-duty performance is crucial, such as in steelmaking or mining equipment.

Durability and Reliability

Built to withstand harsh environments, these bearings offer superior durability and reliability. They are resistant to wear and tear, making them ideal for the demanding conditions of metallurgical and mining operations.

Customization Options

We provide customization to meet specific operational requirements, ensuring optimal performance in diverse applications. Custom sizes, materials, and lubrication methods are available to tailor the bearing to your needs.

Applications

Products are extensively used in various industries, including:

- Metallurgical Industry: Essential for equipment such as blast furnaces and rolling mills.

- Mining Machinery: Utilized in crushers, screens, and feeders where high load-bearing and impact resistance are required.

- Heavy Machinery: Common in large-scale industrial machinery and equipment.

Installation Guide

- Preparation: Ensure that the bearing seat and shaft are clean and free of debris.

- Alignment: Properly align the bearing to avoid uneven wear and potential failure.

- Lubrication: Apply the recommended lubrication to ensure smooth operation and reduce friction.

- Sealing: Ensure that seals are properly installed to prevent contamination.

For detailed installation instructions, refer to our technical documentation or contact our support team.

Maintenance and Care

To ensure the longevity and optimal performance of your Tapered Roller Thrust Bearing:

- Regular Inspection: Check for signs of wear, damage, or misalignment.

- Proper Lubrication: Maintain proper lubrication levels and use high-quality lubricants.

- Clean Environment: Keep the operating environment clean to prevent contamination.

- Timely Replacement: Replace bearings that show signs of significant wear or damage.

FAQ

Q1: What types of loads can Tapered Roller Thrust Bearings handle? A1: They are designed to handle high axial loads and are ideal for applications with significant thrust forces.

Q2: Can Tapered Roller Thrust Bearings be customized? A2: Yes, we offer various customization options including size, material, and lubrication methods to meet specific needs.

Q3: What is the typical operating temperature range for these bearings? A3: They can operate effectively at temperatures up to 150°C (302°F).

Q4: How do I know if my bearing needs maintenance? A4: Regular inspections for signs of wear, damage, or misalignment can indicate when maintenance or replacement is necessary.

Customer Reviews

"CHG Bearing's Tapered Roller Thrust Bearings have been a game-changer for our production line. The quality and durability have significantly improved our equipment's performance." – [Customer Name], Production Manager

"Exceptional service and high-quality bearings. CHG Bearing's expertise and customization options have been invaluable to our mining operations." – [Customer Name], Technical Engineer

Contact Us

For inquiries, orders, or further information, please reach out to us:

- Email: sale@chg-bearing.com

We look forward to assisting you with your bearing needs and providing solutions that enhance your operations.

| Boundary dimensions | Basic load ratings | Designations | Mass | ||||||||

| mm | kN | Current | Original | kg | |||||||

| D | D1 | d1 | T | R | M 1 | M 2 | rmin | Coa | |||

| 150 | 148 | 127 | 48 | 228.6 | M12 | - | 1.5 | 1630 | TTSV150 | 4297/150 | 5 |

| 175 | 173 | 152 | 53 | 228.6 | M12 | - | 1.5 | 2180 | TTSV175 | 4297/175 | 8 |

| 203 | 201 | 178 | 65 | 254 | M12 | - | 1.5 | 2540 | TTSV203 | 4297/203 | 11 |

| 205 | 203 | 178 | 65 | 254 | M20 | - | 1.5 | 3370 | TTSV205 | 4297/205 | 15 |

| 235 | 233 | 208 | 73 | 280 | M20 | - | 1.5 | 3370 | TTSV235 | 4297/235 | 18 |

| 265 | 263 | 229 | 81 | 304.8 | M20 | - | 1.5 | 4130 | TTSV265 | 4297/265 | 24 |

| 320 | 318 | 280 | 95 | 380 | M24 | - | 1.5 | 7370 | TTSV320 | 4297/320 | 42 |

| 377 | 375 | 330 | 112 | 457.2 | M24 | - | 2.5 | 8230 | TTSV377 | 4297/377 | 86 |

| 380 | 378 | 330 | 112 | 457.2 | M24 | M30 | 1.5 | 8220 | TTSV380 | 4297/380 | 67 |

| 410 | 408 | 355 | 122 | 508 | M24 | M30 | 3 | 11300 | TTSV410 | 4297/410 | 115 |

| 440 | 438 | 380 | 130 | 508 | M24 | M36 | 3 | 18500 | TTSV440 | 4297/440 | 140 |

| 495 | 492 | 432 | 146 | 558.8 | M24 | M36 | 3 | 19100 | TTSV495 | 4297/495 | 198 |

| 525 | 522 | 460 | 155 | 635 | M24 | M36 | 3 | 20380 | TTSV525 | 4297/525 | 210 |

| 555 | 552 | 482 | 165 | 635 | M24 | M36 | 3 | 21380 | TTSV555 | 4297/555 | 275 |

| 580 | 577 | 510 | 165 | 710 | M24 | M42 | 3 | 23540 | TTSV580 | 4297/580 | 250 |

| 610 | 607 | 533 | 178 | 762 | M30 | M42 | 3 | 24170 | TTSV610 | 4297/610 | 350 |

| 640 | 637 | 550 | 185 | 762 | M30 | M42 | 3 | 28670 | TTSV640 | 4297/640 | 410 |