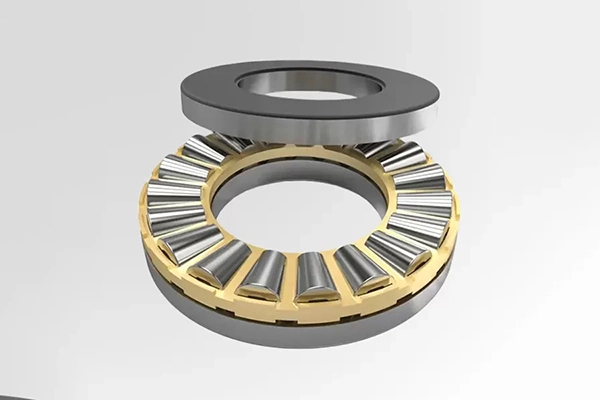

Thrust Roller Bearing

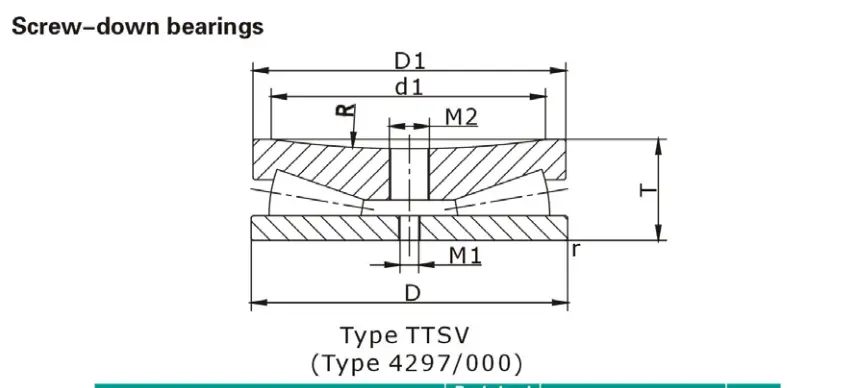

screw-down-bearings

2. Sizes: Inner Diameter; 200-380mm

Outer Diameter: 400-670mm Weight: 75-274kg

3. Feature:Cylindrical roller thrust bearings are separable. They only carry axial loads in one direction and slight shock loads, but their loading capacity is much higher than thrust ball bearings with same dimensions. They can limit axial displacement of shafts or housing in one direction, so can be as axial locating bearings in one direction. the slippage will formed on the raceways because of the linear velocity differences of two ends of rollers while rolling. So the Limiting speed of these bearings is lower than thrust ball bearings, and they are usually applied to low speed applications.

Tapered roller thrust bearings can only carry axial loads and limit axial displacement in one direction, so they can be used as axial locating bearings in one direction. Comparing with cylindrical roller thrust bearings, their loading capacity is higher, relative slippage and limiting speed are lower.

4. Cage: Metal machined solid cages are used for cylindrical roller thrust bearings which are standard design, but otehr cages also can be provided according to customers.

Steel or brass cages are used in tapered roller thrust bearings

5. Application:Cylindrical roller thrust bearings mainly used in heavy machine tools, large power gear boxed for ships, oil rigs, vertical machines, etc.

Tapered roller thrust bearing are widely used in construction machinery, automotives, generating equipments, etc.

6. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

Thrust Roller Bearing: Essential Components for Reliable Equipment

Welcome to our comprehensive guide on thrust roller bearing! Whether you're a purchasing manager, technical engineer, production manager, or company boss, understanding the product is crucial for maintaining and improving the efficiency of your equipment.

What is a Thrust Roller Bearing?

A bearing is a specialized type of bearing designed to handle axial loads—forces that act parallel to the shaft. Unlike other bearings, they are constructed to accommodate significant thrust loads and ensure smooth rotational movement. They are typically used in applications with high axial forces, such as in gearboxes, thrust blocks, and other machinery components.

Why Choose CHG Bearing?

At CHG Bearing, we take pride in being a leading manufacturer and supplier of the product. Here’s why we stand out:

- Customization and Solutions: We offer tailor-made solutions for various working conditions. Whether you need a specific size, structure, or material, our team can provide a customized bearing that meets your exact requirements.

- Experience: With over 30 years in the industry, CHG Bearing has built a solid reputation for quality and reliability. We have successfully partnered with numerous large companies, ensuring our bearings meet the highest standards.

- Innovative Technology: Our commitment to innovation is evident in our portfolio of more than 50 invention patents. We adhere to strict quality standards and have earned certifications such as ISO9001 for quality management and ISO14001 for environmental management.

For more information or to request a quote, feel free to contact us at sale@chg-bearing.com.

Technical Specifications

| Specification | Details |

|---|---|

| Bearing Type | Thrust Roller Bearing |

| Load Capacity | High axial load capacity |

| Materials | Chrome steel , stainless steel , and custom materials |

| Dimensions | Customizable to fit specific requirements |

| Temperature Range | Suitable for high-temperature environments |

| Certification | ISO9001, ISO14001, GJB9001C-2017 |

Benefits of Thrust Roller Bearings

The product offers several key advantages:

- High Load Capacity: Designed to support significant axial loads, making them ideal for heavy-duty applications.

- Durability: Built to withstand harsh conditions, including high temperatures and heavy loads.

- Reduced Maintenance: With high wear resistance, these bearings minimize the need for frequent replacements.

- Customization: Can be tailored to specific needs, including size, material, and lubrication methods.

Applications

Thrust roller bearing is used in a variety of industrial applications, including:

- Metallurgical Equipment: Essential in blast furnaces, rolling mills, and steelmaking equipment.

- Mining Machinery: Commonly used in crushers, vibrating screens, and feeders.

- Gearboxes: Supports thrust loads in various types of gearboxes.

- Thrust Blocks: Provides reliable support for rotating shafts in thrust blocks.

Installation Guide

Proper installation is crucial for the performance and longevity of the product. Follow these steps:

- Preparation: Ensure the bearing and housing are clean and free of contaminants.

- Alignment: Check the alignment of the bearing and shaft to avoid misalignment issues.

- Assembly: Carefully place the bearing into the housing and secure it using appropriate tools.

- Lubrication: Apply the correct lubricant based on the operating conditions and manufacturer recommendations.

For detailed installation instructions, refer to the product manual provided with your bearing.

Maintenance and Care

To ensure optimal performance and extend the life of your bearings, follow these maintenance tips:

- Regular Inspections: Periodically check for signs of wear, contamination, or misalignment.

- Lubrication: Maintain proper lubrication to reduce friction and prevent overheating.

- Cleaning: Keep the bearings clean and debris-free to avoid damage.

- Monitoring: Track the operating conditions and adjust maintenance schedules accordingly.

FAQ

Q: What is the maximum load capacity of a bearing?

A: The maximum load capacity depends on the specific design and size of the bearing. Consult the technical specifications for detailed information.

Q: Can the bearings be customized?

A: Yes, CHG Bearing offers customization options to meet your specific needs, including size, material, and lubrication methods.

Q: How often should the product be replaced?

A: The replacement frequency depends on the operating conditions and maintenance practices. Regular inspections can help determine when replacement is necessary.

Customer Reviews

John D., Production Manager

"CHG Bearings has consistently delivered high-quality thrust roller bearings that have improved the efficiency of our production equipment. Their customization options and quick response time are exceptional."

Sarah L., Technical Engineer

"The precision and durability of CHG Bearings' products have been invaluable for our projects. Their technical support and customization services are top-notch."

Contact Us

For more information or to discuss your specific requirements, contact us at Email: sale@chg-bearing.com. Thank you for choosing CHG Bearing. We look forward to supporting your equipment needs with our high-quality thrust roller bearing!

| Boundary dimensions | Basic load ratings | Part number | Mass | ||||||||

| mm | kN | Current | Original | kg | |||||||

| D | D1 | d1 | T | R | M 1 | M 2 | rmin | Coa | |||

| 150 | 148 | 127 | 48 | 228.6 | M12 | - | 1.5 | 1630 | TTSV150 | 4297/150 | 5 |

| 175 | 173 | 152 | 53 | 228.6 | M12 | - | 1.5 | 2180 | TTSV175 | 4297/175 | 8 |

| 203 | 201 | 178 | 65 | 254 | M12 | - | 1.5 | 2540 | TTSV203 | 4297/203 | 11 |

| 205 | 203 | 178 | 65 | 254 | M20 | - | 1.5 | 3370 | TTSV205 | 4297/205 | 15 |

| 235 | 233 | 208 | 73 | 280 | M20 | - | 1.5 | 3370 | TTSV235 | 4297/235 | 18 |

| 265 | 263 | 229 | 81 | 304.8 | M20 | - | 1.5 | 4130 | TTSV265 | 4297/265 | 24 |

| 320 | 318 | 280 | 95 | 380 | M24 | - | 1.5 | 7370 | TTSV320 | 4297/320 | 42 |

| 377 | 375 | 330 | 112 | 457.2 | M24 | - | 2.5 | 8230 | TTSV377 | 4297/377 | 86 |

| 380 | 378 | 330 | 112 | 457.2 | M24 | M30 | 1.5 | 8220 | TTSV380 | 4297/380 | 67 |

| 410 | 408 | 355 | 122 | 508 | M24 | M30 | 3 | 11300 | TTSV410 | 4297/410 | 115 |

| 440 | 438 | 380 | 130 | 508 | M24 | M36 | 3 | 18500 | TTSV440 | 4297/440 | 140 |

| 495 | 492 | 432 | 146 | 558.8 | M24 | M36 | 3 | 19100 | TTSV495 | 4297/495 | 198 |

| 525 | 522 | 460 | 155 | 635 | M24 | M36 | 3 | 20380 | TTSV525 | 4297/525 | 210 |

| 555 | 552 | 482 | 165 | 635 | M24 | M36 | 3 | 21380 | TTSV555 | 4297/555 | 275 |

| 580 | 577 | 510 | 165 | 710 | M24 | M42 | 3 | 23540 | TTSV580 | 4297/580 | 250 |

| 610 | 607 | 533 | 178 | 762 | M30 | M42 | 3 | 24170 | TTSV610 | 4297/610 | 350 |

| 640 | 637 | 550 | 185 | 762 | M30 | M42 | 3 | 28670 | TTSV640 | 4297/640 | 410 |

| Boundary dimensions | Basic load ratings | Part number | Mass | ||||||||

| mm | kN | Current | Original | kg | |||||||

| D | D1 | d1 | T | R | M 1 | M 2 | rmin | Coa | |||

| 150 | 148 | 127 | 55 | 457.2 | M12 | - | 1.5 | 1630 | TTSX150 | 4379/150 | 7 |

| 175 | 173 | 152 | 62 | 457 | M12 | - | 1.5 | 2180 | TTSX175 | 4379/175 | 11 |

| 205 | 203 | 178 | 76 | 508 | M20 | - | 1.5 | 2540 | TTSX205 | 4379/205 | 18 |

| 235 | 233 | 208 | 85 | 560 | M20 | - | 1.5 | 3370 | TTSX235 | 4379/235 | 26 |

| 265 | 263 | 229 | 95 | 609.6 | M20 | - | 1.5 | 4130 | TTSX265 | 4379/265 | 37 |

| 320 | 318 | 280 | 112 | 762 | M20 | - | 2.5 | 7370 | TTSX320 | 4379/320 | 62 |

| 380 | 378 | 330 | 129 | 914.4 | M24 | M30 | 1.5 | 8550 | TTSX380 | 4379/380 | 101 |

| 410 | 408 | 355 | 142 | 1016 | M24 | M30 | 3 | 11300 | TTSX410 | 4379/410 | 130 |

| 440 | 438 | 380 | 152 | 1016 | M24 | M36 | 3 | 18500 | TTSX440 | 4379/440 | 160 |

| 495 | 492 | 432 | 172 | 1066.8 | M24 | M36 | 3 | 19100 | TTSX495 | 4379/495 | 210 |

| 525 | 522 | 460 | 180 | 1270 | M24 | M36 | 3 | 20380 | TTSX525 | 4379/525 | 250 |

| 555 | 552 | 482 | 192 | 1270 | M24 | M36 | 3 | 21380 | TTSX555 | 4379/555 | 280 |

| 580 | 577 | 510 | 195 | 1422.4 | M24 | M36 | 3 | 21540 | TTSX580 | 4379/580 | 310 |

| 610 | 607 | 533 | 205 | 1520 | M30 | M42 | 3 | 24170 | TTSX610 | 4379/610 | 410 |

| 640 | 637 | 550 | 214.8 | 1740 | M30 | M42 | 3 | 28670 | TTSX640 | 4379/640 | 450 |

| 710 | 705 | 610 | 250 | 1600 | M30 | M42 | 4 | 31540 | TTSX710 | 4379/710 | 850 |

| 750 | 745 | 650 | 260 | 1600 | M30 | M48 | 4 | 38430 | TTSX750 | 4379/750 | 750 |

| 800 | 795 | 700 | 270 | 1700 | M30 | M48 | 5 | 40150 | TTSX800 | 4379/800 | 930 |