Bearings For Wind Turbines

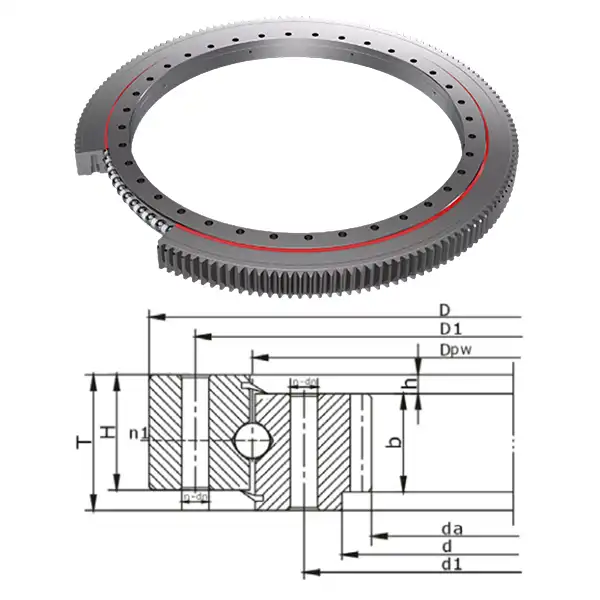

There are various structures of slewing ring bearings, such as four point contact ball slewing bearing, double row angular contact ball slewing bearings, crossed cylindrical roller slewing bearings, crossed tapered roller bearings and three row cylindrical roller slewing bearings, with gears or no gears.

Four point contact ball slewing bearings possess high static loading capacity; crossed cylindrical roller slewing bearings can carry high dynamic loads; crossed tapered roller slewing bearings have high stiffness and rotation accuracy by preloading.

Slewing ring bearings are widely used in cranes, excavation machines, construction machinery, port cargo handling machinery, large turnplates of high precision radars and missile launchers, etc.

Bearings for Wind Turbines: Precision Engineering for Optimal Performance

Bearings for wind turbines are specialized components designed to support and facilitate the rotation of turbine blades. These bearings are critical to the efficient operation of wind turbines, ensuring that the blades can rotate smoothly in response to changing wind directions, thereby maximizing energy capture. Typically, wind turbine bearings must withstand heavy loads, harsh environmental conditions, and continuous operation to ensure long-term reliability and performance.

CHG Bearing: Your Trusted Partner in Wind Turbine Bearings

CHG Bearing is a leading manufacturer and supplier of high-performance bearings. With over 30 years of industry experience and partnerships with major global companies, CHG Bearing offers customized solutions tailored to the specific demands of wind turbine applications. Our company is committed to quality and innovation, holding more than 50 invention patents and certifications including ISO9001 for quality management and ISO14001 for environmental management.

We understand the critical role bearings play in wind turbines, and our products are designed to meet the highest standards of performance and reliability. Whether you need bearings for wind turbines or smaller installations, CHG Bearing has the expertise and technology to provide the ideal solution.

For more information or to discuss your specific requirements, please contact us at sale@chg-bearing.com.

Technical Specifications

| Specification | Description |

|---|---|

| Load Capacity | Customization |

| Rotation Speed | Customization |

| Temperature Range | Customization |

| Material | 42CrMo, 50Mn |

| Lubrication | Advanced grease or oil lubrication |

| Sealing System | Triple-layer sealing for maximum protection |

Benefits of CHG Wind Turbine Bearings

- Durability: Engineered to endure extreme conditions, our bearings for wind turbines offer long service life and minimal maintenance needs.

- Efficiency: Optimized for low friction and smooth rotation, enhancing the overall efficiency of wind turbines.

- Custom Solutions: We provide tailored solutions that meet the specific requirements of different wind turbine models and operational conditions.

- Cost-Effective: High-quality materials and advanced manufacturing techniques ensure competitive pricing without compromising performance.

- Environmental Resistance: Our bearings are designed to resist corrosion, wear, and other environmental challenges.

Applications

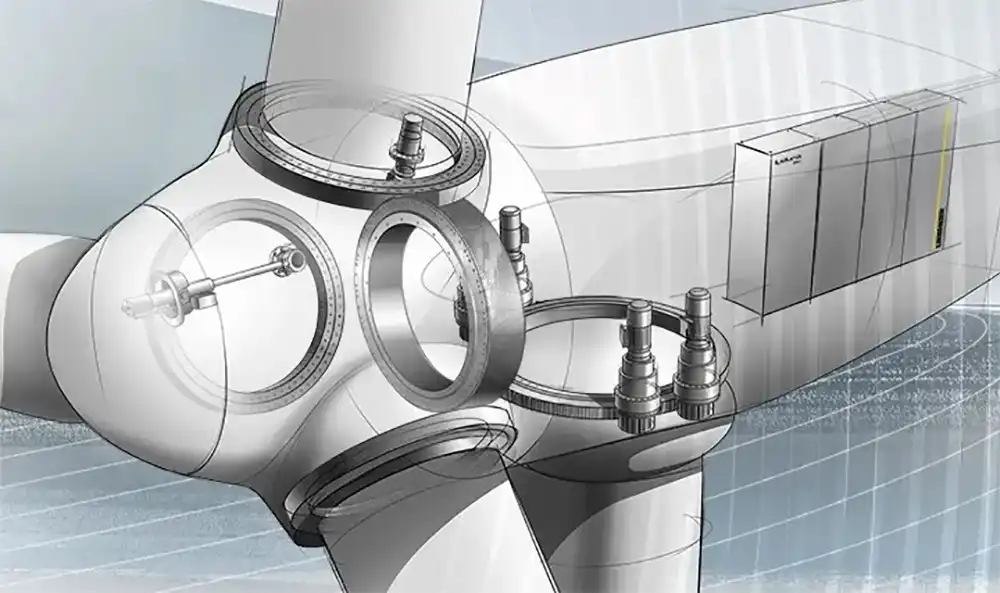

CHG wind turbine bearings are used in various components of wind turbines, including:

- Main Shaft Bearings: Support the main shaft, ensuring smooth and stable rotation.

- Yaw Bearings: Enable the nacelle to rotate and align with the wind direction.

- Pitch Bearings: Adjust the angle of the blades for optimal energy capture.

These bearings are essential for the reliable operation of wind turbines in various environments, from offshore installations to desert wind farms.

Installation Guide

Proper installation of wind turbine bearings is crucial for their performance and longevity. Here’s a brief guide:

- Pre-Installation Check: Ensure all components are clean and free from contaminants.

- Alignment: Carefully align the bearing with the shaft and housing.

- Mounting: Use the appropriate tools to mount the bearing without applying excessive force.

- Lubrication: Apply the recommended lubricant to reduce friction and wear.

- Inspection: After installation, inspect the bearing to ensure proper fit and operation.

Maintenance and Care

To ensure the long-term performance of wind turbine bearings, regular maintenance is essential. Key maintenance practices include:

- Regular Lubrication: Keep the bearings well-lubricated to prevent wear and overheating.

- Routine Inspections: Conduct regular inspections for signs of wear, corrosion, or damage.

- Seal Maintenance: Ensure that seals are intact and functioning properly to protect against contaminants.

By following these maintenance practices, you can extend the lifespan of your wind turbine bearings for wind turbines and minimize the risk of costly downtime.

Frequently Asked Questions (FAQ)

Q: What types of bearings are used in wind turbines?

A: Wind turbines typically use main shaft bearings, yaw bearings, and pitch bearings, each serving a specific function in the turbine's operation.

Q: How long do wind turbine bearings last?

A: With proper maintenance, wind turbine bearings can last up to 20 years, depending on environmental conditions and usage.

Q: Can CHG Bearing provide custom solutions?

A: Yes, we specialize in providing customized bearing solutions tailored to the specific needs of our customers.

Customer Reviews

John D., Wind Farm Manager:

"CHG Bearing has been our go-to supplier for wind turbine bearings for years. Their products are reliable, and their customer service is excellent."

Anna S., Mechanical Engineer:

"We appreciate the technical support CHG provides. Their bearings have significantly improved the efficiency of our turbines."

Contact Us

For inquiries or to request a quote, please contact CHG Bearings For Wind Turbines at sale@chg-bearing.com. Our team is ready to assist you with your wind turbine bearing needs.