Thin Wall Bearing

Thin section bearings are designed to save space, decrease the overall weight, dramatically reduce friction, and provide excellent running accuracy. The special features of the thin section bearings enable customers to downsize their design and cut manufacturing costs without sacrificing bearing performance or life.

Thin Wall Bearing: Your Solution for Precision and Reliability

A Thin Wall Bearing is a high-performance bearing designed to offer precision and durability in applications where space and weight are critical constraints. These bearings are characterized by their reduced thickness, making them ideal for industries where every millimeter counts. They are engineered to handle radial and axial loads while maintaining excellent performance under high-speed conditions.

Why Choose CHG Bearing?

CHG Bearing is a leading manufacturer and supplier of Thin Wall Bearings, committed to providing top-quality solutions tailored to your specific needs. Here's why you should consider partnering with us:

Customization and Solutions: We offer tailored solutions to meet the unique requirements of different working conditions, ensuring optimal performance in your application.

30 Years of Experience: With three decades of industry experience, we have a proven track record of excellence and innovation. We have successfully collaborated with numerous large enterprises, delivering reliable and efficient bearing solutions.

Innovative Expertise: Our company holds over 50 invention patents and has achieved ISO9001 quality management system, ISO14001 environmental management system certifications, and more. These credentials underscore our commitment to quality and innovation.

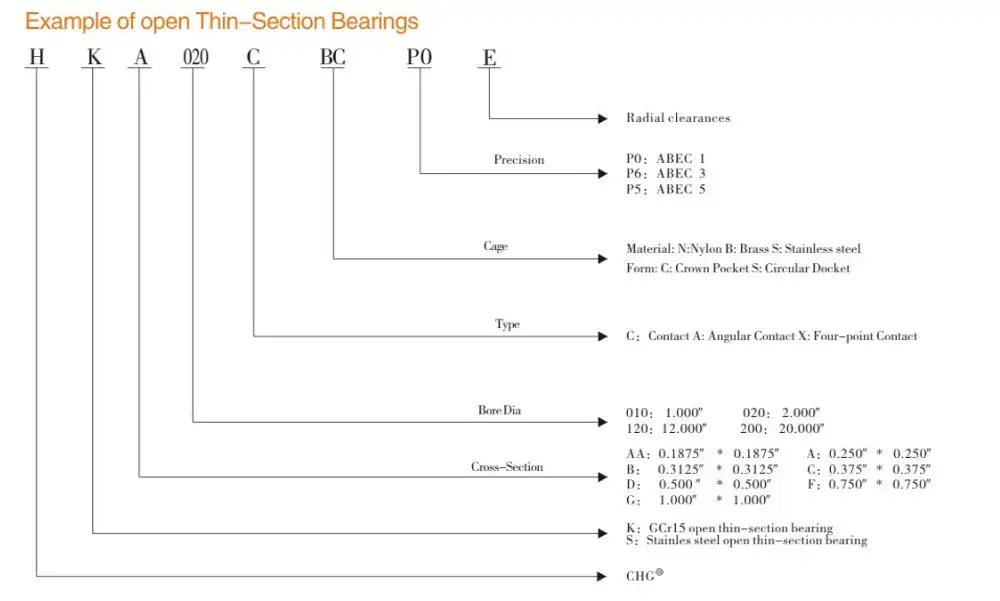

Technical Specifications

| Feature | Specification |

|---|---|

| Material | High-quality steel or stainless steel |

| Thickness | Customized to meet specific needs |

| Load Capacity | Designed for both radial and axial loads |

| Temperature Range | -40°C to +150°C |

| Speed Capability | High-speed operation |

| Certification | ISO9001, ISO14001 |

Benefits of Thin Wall Bearings

- Space Efficiency: Their reduced thickness allows for compact design, making them perfect for applications with limited space.

- Lightweight: Ideal for lightweight machinery and applications where reducing weight is crucial.

- High Precision: Delivers exceptional accuracy and smooth operation, enhancing the performance of high-precision equipment.

- Versatility: Suitable for a range of industries including aerospace, medical equipment, automation, automotive, and consumer electronics.

Applications

Thin Wall Bearings are versatile components used in various high-tech and demanding industries:

- Aerospace: Essential for high-precision applications in aircraft and satellites.

- Medical Equipment: Used in surgical instruments and diagnostic tools requiring reliability and precision.

- Automation and Robotics: Ideal for industrial robots and automation systems that demand lightweight and efficient components.

- Automotive Industry: Perfect for electric vehicles and high-performance automotive parts.

- Consumer Electronics: Found in motion systems for precision instruments and high-end electronic products.

Installation Guide

- Preparation: Ensure the mounting surfaces are clean and free from debris.

- Alignment: Properly align the bearing with the shaft and housing to avoid misalignment issues.

- Insertion: Carefully insert the bearing into the housing. Use appropriate tools to ensure it fits securely without damaging the bearing.

- Lubrication: Apply the recommended lubricant as per the manufacturer's specifications.

- Testing: After installation, test the assembly to ensure smooth operation and proper performance.

Maintenance and Care

- Regular Inspections: Periodically check for signs of wear or damage.

- Lubrication: Maintain proper lubrication to ensure smooth operation and extend bearing life.

- Cleanliness: Keep the bearing and surrounding areas clean to prevent contamination.

- Proper Handling: Avoid exposing the bearing to extreme conditions or misuse.

FAQ

Q: What is the maximum load capacity of Thin Wall Bearings?

A: The load capacity varies depending on the specific design and material. Contact us for details on load capacities for your application.

Q: Can the product handle high-speed applications?

A: Yes, they are designed for high-speed operations. Ensure you select the correct type for your speed requirements.

Q: How do I choose the right product for my application?

A: Consider factors such as load requirements, speed, temperature, and space constraints. Our team can assist in selecting the ideal bearing for your needs.

Q: What industries use our product?

A: They are used in aerospace, medical equipment, automation, automotive, and consumer electronics.

Customer Reviews

"CHG Bearing has consistently delivered high-quality Wall Bearings for our aerospace projects. Their attention to detail and customization options are second to none." – Aerospace Engineer

"We rely on CHG Bearing for all our medical equipment needs. Their Wall Bearings are reliable, precise, and meet all our requirements." – Medical Device Manufacturer

Contact Us

For more information, product inquiries, or to discuss your specific needs, please reach out to us at:

Email: sale@chg-bearing.com

We look forward to providing you with top-notch Thin Wall Bearings and exceptional customer service!