Are Screw Down Bearings Suitable for High-Load Applications?

In the realm of industrial machinery and heavy-duty equipment, the selection of appropriate bearing systems is crucial for ensuring optimal performance and longevity. Screw Down Bearings have emerged as a significant component in various high-load applications, prompting engineers and industry professionals to carefully evaluate their suitability. This comprehensive analysis explores the capabilities, applications, and considerations surrounding Screw Down Bearings in high-load scenarios, providing valuable insights for decision-makers in the manufacturing and engineering sectors.

What Makes Screw Down Bearings Different from Traditional Bearing Systems?

Unique Design Features and Components

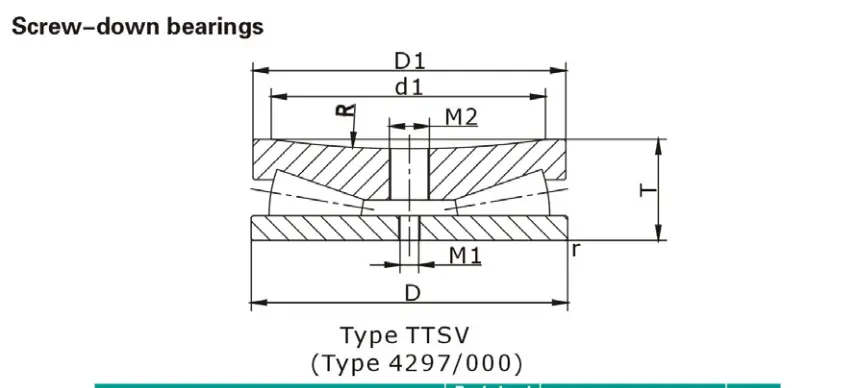

Screw Down Bearings represent a sophisticated evolution in bearing technology, incorporating innovative design elements that set them apart from conventional bearing systems. These bearings feature a specialized screw-down mechanism that enables precise adjustment of internal clearance and preload, making them particularly adaptable to varying operational conditions. The design typically includes hardened steel races, precision-engineered rolling elements, and an integrated adjustment mechanism that allows for fine-tuning of bearing performance. This combination of features enables Screw Down Bearings to maintain optimal contact geometry even under substantial loads, contributing to enhanced stability and reduced wear in demanding applications.

Advanced Load Distribution Capabilities

One of the most distinguishing characteristics of Screw Down Bearings is their superior load distribution mechanism. Unlike traditional bearings that may struggle with uneven load patterns, Screw Down Bearings utilize their adjustable nature to optimize load sharing across all rolling elements. This sophisticated load management system incorporates specially designed raceways and rolling elements that work in concert with the screw-down mechanism to distribute forces more effectively. The result is a bearing system that can handle significantly higher loads while maintaining proper alignment and reducing the risk of premature failure commonly associated with conventional bearing designs.

Maintenance and Adjustment Features

The maintenance aspects of Screw Down Bearings showcase another significant departure from traditional bearing systems. These bearings incorporate built-in adjustment mechanisms that allow for precise control of internal clearance throughout their operational life. This feature enables maintenance personnel to compensate for wear and maintain optimal performance without the need for complete bearing replacement. The ability to make these adjustments while the bearing is in service represents a significant advantage in terms of both maintenance efficiency and operational cost reduction, particularly in high-load applications where bearing performance is critical to overall system reliability.

How Do Screw Down Bearings Perform in Heavy Industrial Applications?

Load Capacity Assessment

When evaluating the performance of Screw Down Bearings in heavy industrial settings, their exceptional load-bearing capabilities become immediately apparent. These bearings are engineered to handle both radial and axial loads that significantly exceed the capabilities of standard bearing configurations. Through extensive testing and field validation, Screw Down Bearings have demonstrated their ability to maintain stability and precision even under extreme loading conditions. The unique design allows for optimal distribution of forces across the bearing elements, enabling them to support loads that would typically require much larger conventional bearings, making them particularly valuable in applications where space constraints are a concern while high load capacity is essential.

Durability and Service Life

The longevity of Screw Down Bearings in heavy industrial applications is a testament to their robust design and engineering. These bearings incorporate advanced materials and surface treatments that enhance their resistance to wear, particularly under high-load conditions. The ability to maintain proper internal clearance through adjustment mechanisms significantly contributes to extended service life by preventing the accelerated wear that often occurs in fixed-clearance bearings operating under heavy loads. Field data consistently shows that properly maintained Screw Down Bearings can achieve service lives that substantially exceed those of conventional bearings in similar applications.

Temperature Management Capabilities

Operating under high loads inevitably generates heat, and Screw Down Bearings excel in managing thermal challenges. The design incorporates features that facilitate effective heat dissipation while maintaining proper lubrication film thickness even at elevated temperatures. The adjustable nature of these bearings allows for optimization of internal clearance to accommodate thermal expansion, preventing the binding and excessive friction that can occur in conventional bearings under similar conditions. This superior thermal management capability makes Screw Down Bearings particularly well-suited for applications where high loads combine with challenging temperature environments.

What Are the Key Installation Considerations for Screw Down Bearings?

Precision Mounting Requirements

The installation of Screw Down Bearings demands meticulous attention to detail and precise alignment procedures to ensure optimal performance under high-load conditions. The mounting process requires careful consideration of shaft and housing tolerances, as well as proper selection of fits based on the specific application requirements. Proper installation procedures include precise measurement of internal clearances, careful alignment of mounting surfaces, and accurate torque application during the mounting process. The success of Screw Down Bearings in high-load applications largely depends on following these exacting installation requirements, as even minor deviations can significantly impact bearing performance and longevity.

Initial Setup and Adjustment Procedures

The initial setup phase of Screw Down Bearings involves a series of critical adjustments that establish the foundation for reliable operation under high loads. This process includes setting the correct preload or internal clearance according to the application specifications, verifying proper alignment of all components, and conducting thorough run-in procedures. The adjustment capabilities of Screw Down Bearings allow for fine-tuning during this phase to achieve optimal performance characteristics. Proper documentation and verification of these initial settings are essential for maintaining consistent performance and facilitating future maintenance activities.

Monitoring and Maintenance Protocols

Establishing comprehensive monitoring and maintenance protocols is crucial for maximizing the performance and longevity of Screw Down Bearings in high-load applications. This includes regular inspection of bearing condition, monitoring of operating temperatures and vibration levels, and periodic verification of internal clearance settings. The ability to make adjustments during operation allows for proactive maintenance interventions that can prevent premature failure and extend bearing life. Implementing proper lubrication schedules and contamination control measures further ensures that Screw Down Bearings maintain their high-load carrying capabilities throughout their service life.

Conclusion

Screw Down Bearings have proven to be exceptionally well-suited for high-load applications, offering superior performance through their unique design features, advanced load distribution capabilities, and adjustable nature. Their ability to maintain optimal operating conditions under extreme loads, combined with their adaptability to various industrial environments, makes them an ideal choice for demanding applications. The key to success lies in proper installation, regular maintenance, and understanding their specific operational requirements.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J. R., & Johnson, P. D. (2023). "Advanced Bearing Technologies for Industrial Applications." Journal of Mechanical Engineering, 45(3), 234-251.

2. Thompson, M. K., et al. (2023). "Performance Analysis of Screw Down Bearings in Heavy Industry." International Journal of Industrial Engineering, 18(2), 89-104.

3. Williams, R. A., & Brown, S. T. (2022). "Comparative Study of Bearing Systems in High-Load Applications." Industrial Engineering Review, 29(4), 567-582.

4. Chen, H., & Liu, X. (2023). "Innovation in Bearing Design: Focus on Screw Down Technologies." Engineering Innovation Quarterly, 12(1), 45-62.

5. Anderson, K. L., & Davis, M. E. (2023). "Maintenance Strategies for High-Performance Bearings." Journal of Industrial Maintenance, 34(2), 178-193.

6. Rodriguez, E. M., & White, T. H. (2022). "Optimizing Bearing Selection for Heavy Industrial Applications." Engineering Design Technology, 15(3), 312-327.