When looking at crossed cylindrical roller slewing bearings for use in industry, the prices from Chinese and Japanese makers show important market changes. Chinese companies usually charge 30% to 40% less, while Japanese companies charge more because they offer better accuracy. Procurement managers need to know about these price models so they can make good choices based on the needs of the project and the budget.

Market Overview: Understanding Global Slewing Bearing Pricing Dynamics

The global market for precision bearing systems shows how the cost of making things differs around the world. Chinese providers have built competitive edges through large-scale production and better supply lines. Japanese makers keep their high-end status by using modern metals and strict quality control.

A study of the market shows three main reasons for the price of goods:

- The cost of finding materials changes by 15–25% in different areas.

- Scale savings in manufacturing are very different.

- The standards for quality approval affect the price in the end.

- Heavy machinery needs to be able to count on spinning accuracy and a long service life. The accuracy of the making of the bearing inner and outer rings has a direct effect on how well the equipment works when it is in harsh settings.

If you need cheap solutions for standard uses, makers in China offer the best options. Japanese providers might better meet special needs when ultra-precision and low range difference are required.

Technical Specifications Comparison: Performance vs Cost Analysis

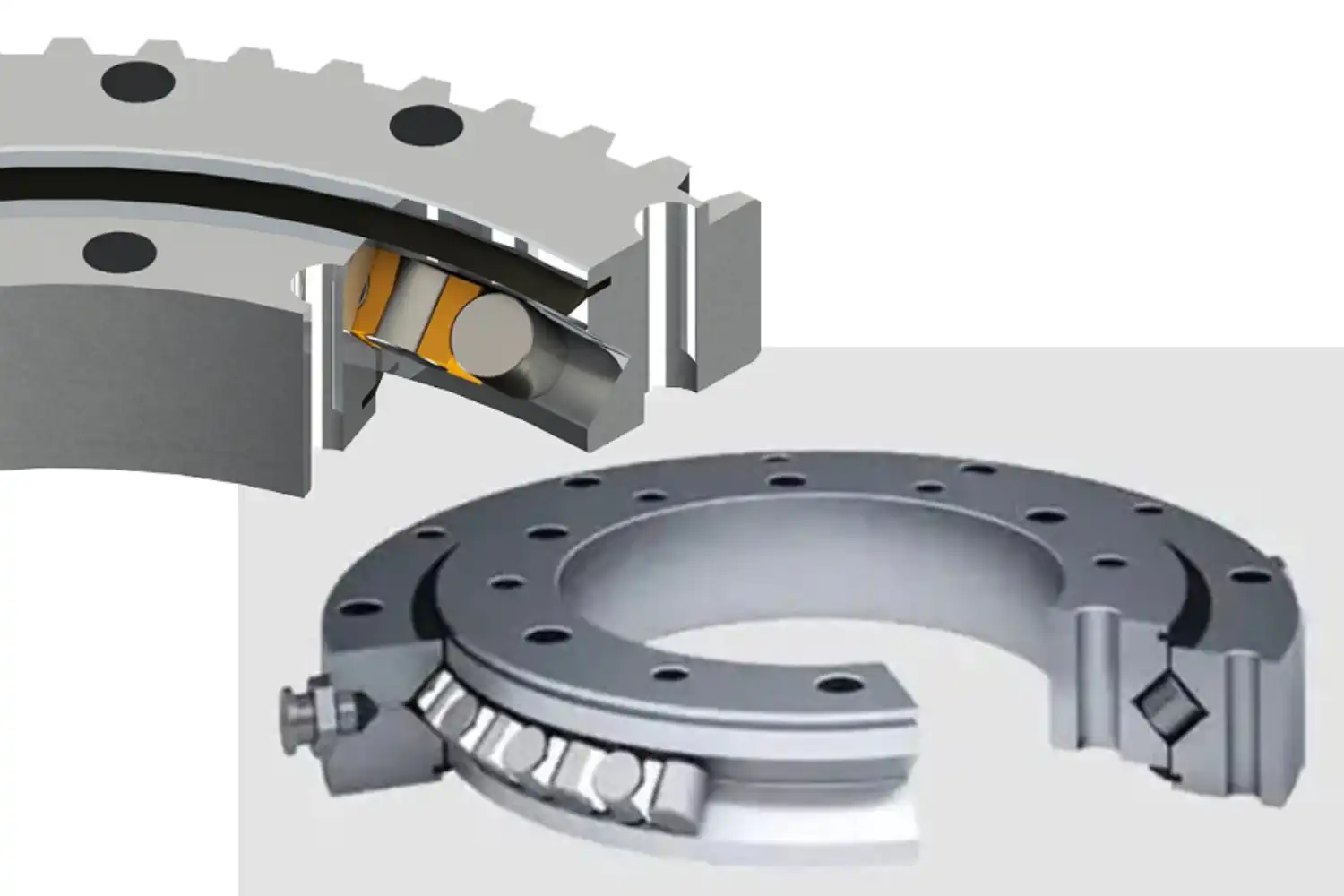

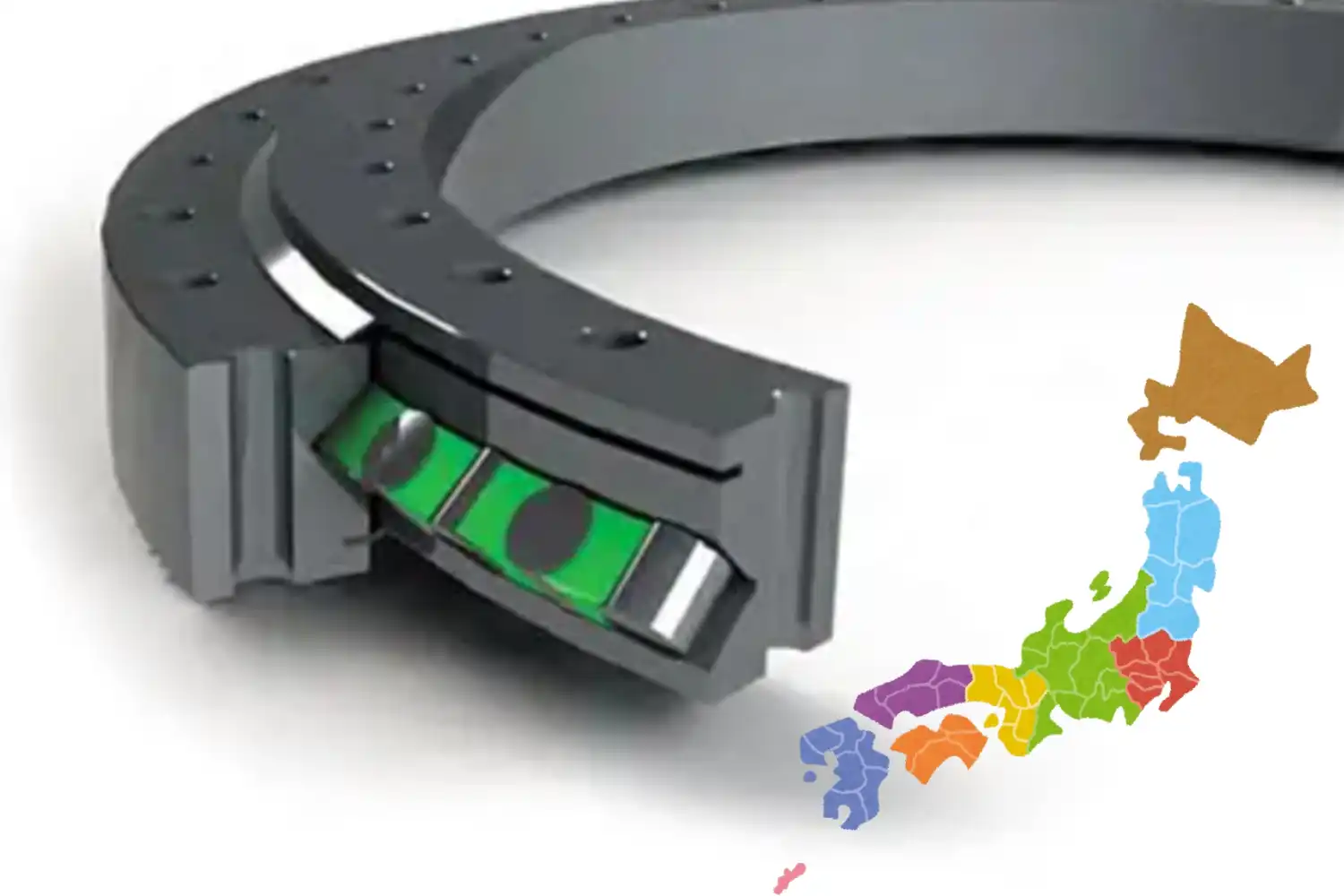

Crossed cylindrical roller slewing bearing technology shows a range of performance traits depending on where they are made. In the last few years, Chinese makers have made a lot of progress in technical areas, especially when it comes to making big-diameter bearings.

Important differences in specifications are:

- Dimensional accuracy: Japanese bearings keep limits of ±2–3 microns.

- Chinese factories meet precise standards of ±5–8 microns.

- Load capacity scores show very small differences in efficiency.

- Premium Japanese goods can handle 8% to 12% more vertical load than high-quality Chinese goods, according to tests done by independent labs. The radial load capacity readings show even less difference, usually within 5% to 7% range.

The compact design strategy varies by maker. For example, Japanese companies focus on making things as light as possible, while Chinese companies focus on making things as strong as possible. The high stiffness features of goods from both areas' quality tiers are still similar.

If you need the most exact standards for industrial equipment bearings, you might want to try the Japanese specs. Chinese options are a great deal for building equipment that needs to bear big loads.

Cost Structure Analysis: Breaking Down Price Components

Manufacturing cost analysis reveals distinct economic advantages across different production approaches. Material costs represent approximately 35-40% of total bearing production expenses, with significant variations in steel sourcing strategies.

Primary cost components breakdown:

- Raw material procurement: Chinese suppliers benefit from domestic steel production

- Labor efficiency: Automated production lines reduce per-unit costs

- Quality control investments: Japanese manufacturers allocate higher percentages to testing

- Research and development: Innovation costs impact long-term pricing strategies

Chinese manufacturers leverage economies of scale through higher volume production runs. Annual production capacities often exceed Japanese facilities by 200-300% margins, enabling lower per-unit overhead allocation.

Currency fluctuations affect pricing stability differently across regions. Yen appreciation historically creates cost pressures for Japanese suppliers, while RMB stability supports predictable Chinese pricing structures.

If you need budget optimization for large procurement volumes, Chinese suppliers provide scalable cost advantages. For specialized low-volume applications requiring premium materials, Japanese manufacturers offer tailored solutions.

Quality Standards and Certification Impact on Pricing

Quality certification requirements significantly influence final product pricing across different manufacturing regions. Japanese suppliers typically invest 12-15% of production costs in quality assurance processes, while Chinese manufacturers allocate 8-10% for similar functions.

Certification impacts include:

- ISO 9001 compliance adds 3-5% to manufacturing costs

- Industry-specific certifications increase expenses by 5-8%

- Third-party testing requirements contribute an additional 2-3% costs

Slewing ring applications in critical machinery demand comprehensive quality documentation. Japanese manufacturers traditionally excel in documentation completeness, providing detailed material traceability and performance verification data.

Chinese suppliers have substantially improved quality management systems, with leading manufacturers achieving comparable certification levels. The gap in quality assurance capabilities continues to narrow as Chinese companies invest in advanced testing equipment and process controls.

Low-friction characteristics depend heavily on surface finish quality and lubrication engineering. Both manufacturing regions demonstrate capabilities to achieve specified friction coefficients within application requirements.

If you need extensive quality documentation for regulatory compliance, Japanese suppliers typically provide comprehensive certification packages. For applications with standard quality requirements, Chinese manufacturers offer excellent performance at competitive prices.

Application-Specific Performance Considerations

Different industrial applications present unique performance requirements that influence optimal supplier selection. Industrial machinery applications demand specific combinations of load capacity, rotational precision, and environmental resistance.

Performance analysis by application type:

- Wind turbine bearing: Chinese manufacturers excel in large-scale production

- Robotic arm bearing: Japanese precision advantages become apparent

- Turntable bearing: Both regions provide suitable solutions

- Construction equipment bearing: Chinese durability proves cost-effective

Environmental conditions significantly affect bearing performance and longevity. Harsh operating environments require enhanced sealing systems and specialized lubrication approaches. Chinese manufacturers have developed robust solutions for demanding applications, particularly in mining and heavy construction sectors.

Temperature stability varies between manufacturing approaches, with Japanese bearings typically maintaining tighter tolerances across broader temperature ranges. Chinese alternatives demonstrate adequate performance for standard operating conditions while offering substantial cost savings.

Maintenance requirements differ based on manufacturing quality and design philosophy. Japanese bearings often require less frequent maintenance interventions, while Chinese products may need more regular inspection schedules to ensure optimal performance.

If you need bearings for extreme environmental conditions, Japanese engineering may provide superior longevity. For standard industrial applications with regular maintenance capabilities, Chinese solutions deliver excellent value.

Huigong's Crossed Cylindrical Roller Slewing Bearings Advantages

Luoyang Huigong Bearing Technology stands out as a premier manufacturer in the competitive bearing market, offering exceptional value through innovative engineering and proven reliability. Our crossed cylindrical roller slewing bearings deliver superior performance across diverse industrial applications while maintaining cost-effective pricing structures.

Key advantages of Huigong's bearing solutions:

- Advanced Manufacturing Capability: Over 150 sets of precision production equipment ensure consistent quality and dimensional accuracy within ±5 micron tolerances

- Comprehensive Size Range: Complete product portfolio covering inner diameters from 320-4272mm and outer diameters up to 4726mm, accommodating diverse application requirements

- Proven Load Performance: Engineered to handle combined axial, radial, and moment loads simultaneously with load ratings exceeding 3100kg capacity

- Superior Material Selection: High-grade steel options, including 50Mn, 42CrMo, and S48C materials ensure optimal performance in demanding environments

- Rigorous Quality Control: Over 70 testing equipment units, including CMM, metallographic microscopes, and friction torque testers,s guarantee product reliability

- Flexible Configuration Options: Available in external gear, internal gear, and no gear configurations to match specific application requirements

- Extended Service Life: Precision cross-roller arrangement design provides exceptional stability and impact resistance for long-term operation

Long-term Value Proposition Analysis

Total cost of ownership calculations reveal important considerations beyond initial purchase prices. Maintenance requirements, replacement frequencies, and operational efficiency impacts contribute significantly to long-term value assessments.

Value analysis components:

- Initial procurement costs represent 25-30% of total ownership expenses

- Maintenance and replacement costs account for 40-50% over equipment lifetime

- Operational efficiency impacts contribute 20-25% of total value considerations

Chinese manufacturers increasingly demonstrate competitive long-term value propositions through improved product durability and comprehensive support services. Leading Chinese suppliers now offer extended warranty programs and technical support comparable to traditional premium suppliers.

Spare parts availability affects long-term operational costs significantly. Chinese manufacturers typically maintain larger inventory stocks and shorter delivery times for replacement components, reducing equipment downtime expenses.

Technology transfer and local support capabilities provide additional value considerations. Chinese suppliers often offer more flexible technical collaboration arrangements and local engineering support services.

If you need comprehensive long-term support with local presence, Chinese manufacturers often provide superior accessibility. For applications requiring minimal maintenance intervention, Japanese precision engineering may optimize total ownership costs.

Conclusion

The price analysis between Chinese and Japanese crossed cylindrical roller slewing bearings reveals distinct value propositions for different application requirements. Chinese manufacturers offer compelling cost advantages while achieving competitive technical performance levels. Japanese suppliers maintain premium positioning through enhanced precision capabilities and comprehensive quality documentation.

Procurement decisions should consider the total cost of ownership, application-specific requirements, and long-term support needs. Both manufacturing regions provide viable solutions for industrial machinery applications, with selection criteria depending on specific performance priorities and budget considerations.

Modern Chinese manufacturers like Huigong demonstrate exceptional capabilities in delivering high-quality bearing solutions at competitive prices, making them attractive alternatives for cost-conscious procurement strategies without compromising performance standards.

Choose Huigong for Superior Crossed Cylindrical Roller Slewing Bearings Solutions

Selecting the right crossed cylindrical roller slewing bearings manufacturer requires careful evaluation of technical capabilities, cost structures, and long-term support commitments. Huigong combines competitive pricing with advanced manufacturing expertise, delivering exceptional value for demanding industrial applications.

Our comprehensive product range addresses diverse application requirements across heavy industry sectors. With proven expertise in large-diameter bearing manufacturing and custom solution development, Huigong serves as your trusted partner for critical machinery applications.

Quality assurance remains paramount in our manufacturing processes, utilizing advanced testing equipment and rigorous inspection protocols. Our engineering team provides comprehensive technical support throughout project lifecycles, ensuring optimal bearing selection and application success.

Leading companies worldwide rely on Huigong as their preferred crossed cylindrical roller slewing bearings supplier for mission-critical applications. Our commitment to continuous innovation and customer satisfaction drives ongoing product development and service enhancement initiatives.

Experience the Huigong advantage through personalized consultation and tailored bearing solutions. Our technical specialists evaluate specific application requirements and recommend optimal bearing configurations for maximum performance and value.

Ready to explore how Huigong's advanced bearing solutions can enhance your equipment performance? Contact our engineering team today to discuss your specific requirements and receive detailed technical recommendations. Reach out to us at sale@chg-bearing.com and discover why industry leaders choose Huigong for their most demanding applications.