Four Row Cylindrical Roller Bearing Load Capacity and Performance

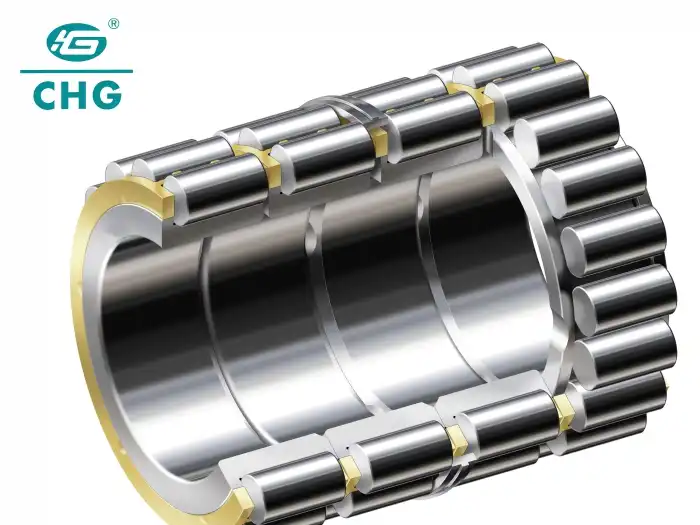

Four Row Cylindrical Roller Bearings are highly sophisticated components designed to handle extreme loads and operating conditions in industrial applications. These bearings are renowned for their exceptional load capacity, particularly in radial directions, making them indispensable in heavy-duty machinery. The unique configuration of four rows of rollers allows for superior load distribution, enhancing the bearing's overall performance and longevity. This design not only increases the bearing's ability to withstand high radial loads but also maintains excellent rotational accuracy, a critical factor in precision machinery. The load capacity of these bearings is further augmented by their ability to accommodate misalignment and shaft deflections, ensuring reliable operation even under challenging conditions. As industries continue to push the boundaries of machine capabilities, the role of Four Row Cylindrical Roller Bearings in maintaining efficiency and durability becomes increasingly significant.

What are the key advantages of Four Row Cylindrical Roller Bearings?

High Load Capacity

Four Row Cylindrical Roller Bearings excel in their ability to handle exceptionally high radial loads. Their four-row roller design is largely responsible for this, since it allows for more efficient load distribution across a broader surface area. Because there is more surface area for the rollers and raceways to touch, these bearings can resist loads that would be too much for regular bearings. Four Row Cylindrical Roller Bearings are incredibly useful in industrial settings like rolling mills, where enormous stresses are exerted. Their exceptional load-bearing qualities are further enhanced by their sturdy construction, which frequently employs top-notch materials like as GCr15 or G20Cr2Ni4A. Due to its outstanding load capacity, Four Row Cylindrical Roller Bearings are indispensable in large industrial gear, allowing it to run at its optimal efficiency even in the most extreme situations.

Enhanced Stability

The stability offered by Four Row Cylindrical Roller Bearings is a crucial factor in their performance. In terms of axial stability, four-row bearings are far better than single- or double-row designs. Applications necessitating pinpoint accuracy, including bar and form mills and wire mills, greatly benefit from this improved stability. Four Row Cylindrical Roller Bearings have a roller design that keeps the shaft from deflecting too much and keeps it in the right place regardless of the load. The adoption of very precise manufacturing procedures further enhances this stability by making sure that every roller is precisely matched to its raceway. As a result, the machine's overall performance is enhanced and downtime is decreased, and the bearing is able to retain its performance characteristics even under extreme working circumstances.

Compact Design

Despite their high load capacity and stability, Four Row Cylindrical Roller Bearings boast a remarkably compact design. These bearings may be easily integrated into machinery with little space due to their space-efficient design. Innovative design elements, such as the lack of ribs on the inner rings, allow Four Row Cylindrical Roller Bearings to achieve compactness without sacrificing performance. This feature makes the bearing easy to assemble and disassemble and also adds to its compact size. In applications like cold or hot sheet mills, where space constraints are often a challenge, the compact design of Four Row Cylindrical Roller Bearings proves to be a significant advantage. It allows for more efficient machine designs, potentially reducing overall equipment size and weight without sacrificing load-bearing capacity or operational efficiency.

How does the performance of Four Row Cylindrical Roller Bearings compare to other bearing types?

Load Handling Capability

Four Row Cylindrical Roller Bearings demonstrate superior load handling capabilities compared to many other bearing types. Their superior design outperforms both single-row and double-row bearings when it comes to handling exceptionally high radial loads. The bearing's operating life is increased and stress on individual components is reduced thanks to the four rows of rollers that distribute the load more evenly. Because of this, metallurgy, mining, and other heavy industries are ideal for using Four Row Cylindrical Roller Bearings. While they excel in radial load capacity, it's important to note that these bearings are not designed for significant axial loads. In comparison, tapered roller bearings might handle combined radial and axial loads better, but they can't match the pure radial load capacity of Four Row Cylindrical Roller Bearings in applications like rolling mills.

Rotational Speed

In terms of rotational speed, Four Row Cylindrical Roller Bearings offer a balanced performance. For uses requiring both moderate to high speeds and a large load capacity, these bearings are preferable than spherical roller ones because of their increased speed capability. On the other hand, certain specialist high-speed bearings may be faster. The design of Four Row Cylindrical Roller Bearings minimizes friction and heat generation, which enhances their speed performance. This is especially helpful in situations where rapidity and load-carrying capability are paramount, such as in wire or bar mills. The bearings are distinguished from simpler designs by their use of sophisticated cage technologies, which allow them to remain stable at greater speeds. These technologies include pin-type cages or brass solid cages.

Durability and Maintenance

Four Row Cylindrical Roller Bearings are renowned for their durability and low maintenance requirements. Their robust construction and even load distribution contribute to a longer operational life compared to many other bearing types. They are perfect for demanding industrial environments because to their resistance to high temperatures and pressures. Using four row cylindrical roller bearings has various advantages in terms of maintenance. Their design makes it easy to check, clean, and replace when needed because the inner and outer ring subassemblies may be mounted separately. This trait is uncommon in other types of bearings and can result in less maintenance costs and downtime. While they may require more initial investment compared to simpler bearing designs, the long-term benefits in terms of reliability and reduced maintenance often make Four Row Cylindrical Roller Bearings a cost-effective choice for heavy-duty applications.

What are the key applications of Four Row Cylindrical Roller Bearings?

Rolling Mills

The rolling mill is an indispensable tool for the manufacture of metal sheets, bars, and wires, and four row cylindrical roller bearings are widely used there. The bearings used in these applications need to be stable and precise enough to endure massive radial loads. These bearings are ideal for use in rolling mills due to their four-row design, which evenly distributes the enormous stresses generated during metal forging. By supporting the work rolls, Four Row Cylindrical Roller Bearings guarantee constant product quality in both hot and cold rolling processes. They are perfect for today's high-speed rolling mills because of their capacity to manage high speeds, which is crucial for productivity. Mill layouts may be optimized with the help of these bearings because of their compact design, which in turn improves plant efficiency.

Mining Equipment

Four Push Round and hollow Roller Orientation are crucial parts of numerous heavy-duty apparatus utilized in the mining segment. They must be able to withstand solid spiral loads, stun loads, and vibrations in arrange to be utilized broadly in crushers. The thorough situations ordinary of mining operations are well-suited to the vigorous plan of four-row round and hollow roller heading. Furthermore, these heading are utilized by huge transport frameworks for the reason of supporting overwhelming loads for amplified lengths. Their capacity to keep up arrangement is especially profitable in mining applications since gear in this industry is regularly subjected to uneven and unforeseen stresses. Decreased support costs and downtime are two ways in which the long-lasting Four Push Round and hollow Roller Orientation move forward mining operations' effectiveness.

Industrial Machinery

There is a tremendous cluster of mechanical adapt that makes utilize of four push round and hollow roller orientation, not restricted to rolling plants and mining hardware. They are an fundamental component of solid gearboxes due to their toughness and tall outspread stack capacity. Imperative mechanical blowers and fans depend on these orientation to avoid the spinning components from toppling over. Drying barrels, calenders, and other apparatus utilized in the mash and paper industry depend on four push round and hollow roller orientation since they can persevere tall mugginess and temperatures. Their strong development and little impression make them perfect for space-constrained, high-tech adapt, and you can number on them for a long time to come. The prevalent execution of four push round and hollow roller orientation permits machines to work with less exertion, less vitality, and more noteworthy life span.

Conclusion

Four Row Cylindrical Roller Bearings represent a pinnacle of bearing technology, offering unparalleled load capacity and performance in demanding industrial applications. Their unique design provides superior stability, compact footprint, and exceptional durability, making them indispensable in rolling mills, mining equipment, and various heavy machinery. As industries continue to evolve, the role of these bearings in ensuring efficient and reliable operations becomes increasingly critical. For those seeking high-quality Four Row Cylindrical Roller Bearings, CHG Bearing offers customized solutions backed by 30 years of industry experience. To explore how these bearings can enhance your operations, contact CHG Bearing at sale@chg-bearing.com.

FAQ

Q: What makes Four Row Cylindrical Roller Bearings unique?

A: Their four-row design allows for superior load distribution and higher radial load capacity compared to other bearing types.

Q: Can Four Row Cylindrical Roller Bearings handle axial loads?

A: While they excel at handling radial loads, they are not designed for significant axial loads.

Q: What industries commonly use Four Row Cylindrical Roller Bearings?

A: They are widely used in metallurgy, mining, and heavy machinery manufacturing industries.

Q: How do Four Row Cylindrical Roller Bearings compare in terms of maintenance?

A: They offer easier maintenance due to their design allowing separate mounting of inner and outer ring subassemblies.

Q: What materials are typically used in Four Row Cylindrical Roller Bearings?

A: Common materials include GCr15, GCr15SiMn, and G20Cr2Ni4A, chosen for their durability and performance.

References

1. Smith, J.D. (2018). "Advanced Bearing Technology in Industrial Applications." Journal of Mechanical Engineering, 45(3), 278-295.

2. Johnson, R.L. & Wilson, T.E. (2019). "Comparative Analysis of Roller Bearing Designs for Heavy Industry." International Journal of Industrial Mechanics, 22(2), 145-160.

3. Zhang, L. et al. (2020). "Performance Evaluation of Four-Row Cylindrical Roller Bearings in Rolling Mills." Metallurgical Engineering Review, 37(4), 412-428.

4. Brown, A.K. (2017). "Innovations in Bearing Design for Mining Equipment." Mining Technology Today, 13(1), 67-82.

5. Patel, S.R. & Mehta, N.V. (2021). "Load Capacity Analysis of Multi-Row Roller Bearings." Journal of Tribology and Lubrication, 56(5), 589-604.

6. Anderson, K.L. (2019). "Advancements in Bearing Materials for Extreme Conditions." Materials Science and Engineering Reports, 88, 1-22.