How Do I Choose the correct RB Cross Roller Bearing For My System?

Selecting the right RB Cross Roller Bearing is crucial for ensuring optimal system performance and longevity in precision engineering applications. These specialized bearings, known for their high accuracy and load-bearing capabilities, require careful consideration of multiple factors to make an informed choice. Understanding the specific requirements of your application, along with the bearing's technical specifications, is essential for making the right selection that will enhance your system's efficiency and reliability.

What are the key load capacity considerations when selecting RB Cross Roller Bearings?

The load capacity assessment is fundamental when choosing RB Cross Roller Bearings, as it directly impacts the bearing's performance and lifespan. When evaluating load capacity requirements, engineers must consider both static and dynamic load ratings. Static load capacity refers to the maximum load the bearing can sustain while stationary without permanent deformation, while dynamic load capacity indicates the load the bearing can handle while in motion.

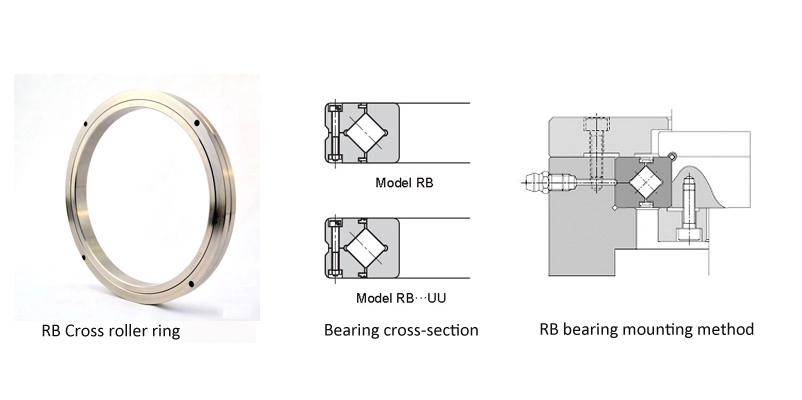

The load distribution pattern in cross roller bearings is unique due to their design, where cylindrical rollers are arranged perpendicular to each other. This configuration allows them to handle complex loads from multiple directions simultaneously. When calculating load requirements, it's essential to account for both radial and axial loads, as well as any moment loads that may be present in the application.

Environmental factors also play a crucial role in load capacity considerations. Temperature fluctuations can affect the bearing's material properties and, consequently, its load-bearing capabilities. Higher operating temperatures may require derating the load capacity to ensure safe operation. Additionally, the presence of shock loads or vibrations in the system might necessitate selecting a bearing with higher load ratings than the nominal calculated requirements.

The mounting arrangement significantly influences the actual load distribution across the bearing. Proper preload application is crucial for achieving optimal performance, as it eliminates internal clearances and enhances rigidity. However, excessive preload can reduce the bearing's service life and increase friction, while insufficient preload may result in poor accuracy and reduced stiffness.

To ensure accurate load capacity selection, engineers should consider the duty cycle of the application, including operating speeds, acceleration/deceleration rates, and the frequency of start-stop operations. These factors affect the bearing's fatigue life and should be factored into the selection process to achieve the desired service life.

How does bearing precision grade affect system performance in RB Cross Roller Bearings?

Bearing precision grade is a critical parameter that directly influences system accuracy, smoothness of operation, and overall performance. RB Cross Roller Bearings are manufactured in various precision grades, each suited to specific application requirements. The precision grade affects running accuracy, which includes parameters such as radial runout, axial runout, and parallelism.

High-precision applications, such as semiconductor manufacturing equipment, robotics, and medical devices, typically require bearings with higher precision grades. These grades offer tighter tolerances in terms of dimensional accuracy and running characteristics. The selection of precision grade should be based on the application's accuracy requirements, considering factors such as positioning accuracy, motion smoothness, and repeatability.

Manufacturing tolerances associated with different precision grades affect not only the bearing's performance but also its cost. Higher precision grades require more sophisticated manufacturing processes and quality control measures, resulting in higher production costs. Therefore, it's essential to balance the precision requirements with budget constraints while ensuring that the selected grade meets the application's minimum performance requirements.

The relationship between precision grade and mounting accuracy is particularly important. Even the highest precision bearing will not perform optimally if mounted incorrectly or if the mounting surfaces do not meet the required geometrical tolerances. The supporting structure's stiffness and geometrical accuracy should be compatible with the bearing's precision grade to achieve the desired system performance.

Temperature management becomes increasingly critical with higher precision grades. Thermal expansion and contraction can significantly impact the bearing's running accuracy, particularly in high-precision applications. Proper consideration should be given to temperature control and thermal compensation methods when selecting precision grades for temperature-sensitive applications.

What maintenance and lubrication requirements should be considered for RB Cross Roller Bearings?

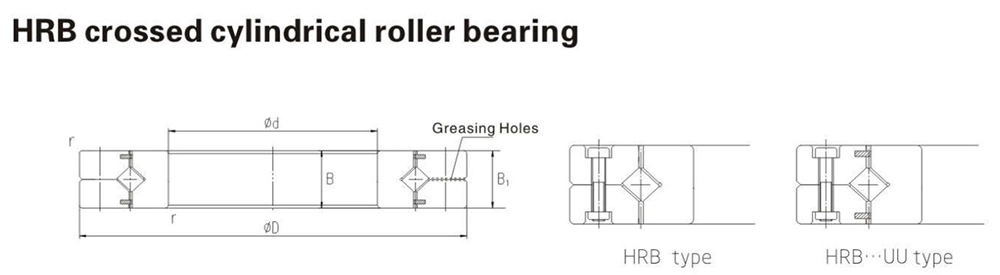

Maintenance and lubrication considerations are vital for ensuring the long-term reliability and performance of RB Cross Roller Bearings. Proper lubrication is essential for reducing friction, preventing wear, protecting against corrosion, and dissipating heat generated during operation. The selection of appropriate lubricant type and lubrication method depends on various factors, including operating conditions, environment, and application requirements.

The operating speed and load conditions significantly influence lubrication requirements. High-speed applications may require different lubrication strategies compared to slow-speed operations. The lubricant's viscosity should be selected based on the operating temperature range and speed conditions to maintain an adequate lubricating film between the rolling elements and raceways.

Environmental conditions play a crucial role in determining maintenance requirements. Applications exposed to contamination, moisture, or extreme temperatures may require special sealing arrangements and more frequent maintenance intervals. The selection of sealing solutions should be based on the operating environment while considering their impact on bearing friction and heat generation.

Preventive maintenance strategies should be developed based on the application's criticality and operating conditions. This includes establishing inspection schedules, monitoring bearing condition through various parameters such as vibration and temperature, and implementing appropriate relubrication intervals. The maintenance program should also include procedures for proper handling and storage of spare bearings to maintain their precision characteristics.

Regular monitoring of RB Cross Roller Bearing condition can help detect potential issues before they lead to failure. Modern condition monitoring techniques, including vibration analysis and temperature monitoring, can be integrated into the maintenance program to optimize bearing performance and prevent unexpected downtime. The implementation of proper maintenance procedures ensures that the selected bearing achieves its expected service life while maintaining system performance.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. THK Technical Journal. "Cross Roller Bearing Selection Guide." THK Manufacturing, 2023.

2. NSK Precision Machinery. "Bearing Selection and Mounting Guidelines." NSK Ltd., 2022.

3. IKO International. "Engineering Guide: Precision Roller Bearings." IKO Bearings, 2023.

4. SKF Group. "Railway Technical Handbook." SKF Precision Bearings, 2022.

5. Schaeffler Technologies. "The Design of Rolling Bearing Mountings." Schaeffler AG, 2023.

6. JTEKT Corporation. "Precision Rolling Bearings Technical Guide." JTEKT, 2022.

7. NTN Corporation. "Technical Review: Cross Roller Bearings." NTN Bearing Corp., 2023.

8. American Bearing Manufacturers Association. "Load Ratings and Fatigue Life." ABMA, 2022.

9. Journal of Mechanical Engineering. "Advances in Precision Bearing Technology." Vol. 45, 2023.

10. International Organization for Standardization. "Rolling Bearings - Dynamic Load Ratings and Rating Life." ISO 281:2007.