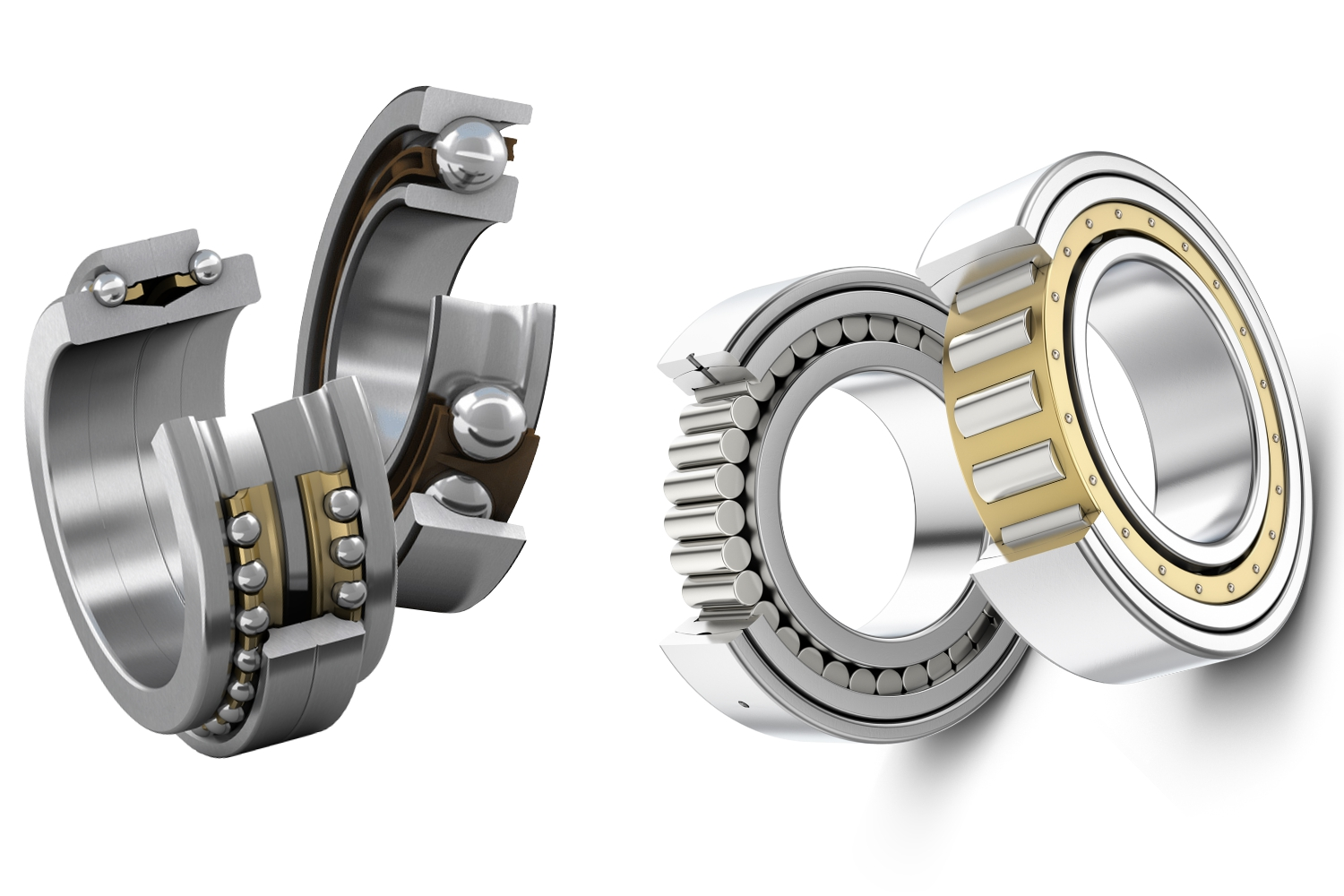

How Do Spherical Rollers Differ From Cylindrical Rollers?

Spherical rollers and cylindrical rollers are both crucial components in bearing technology, but they serve different purposes and have distinct characteristics. Spherical rollers, with their unique rounded shape, are designed to handle both radial and axial loads while accommodating misalignment between the shaft and housing. This versatility makes them ideal for applications where heavy loads and potential misalignment issues are present. In contrast, cylindrical rollers are straight and primarily designed for radial load bearing. The key difference lies in their geometry: spherical rollers have a curved surface that allows for self-alignment, whereas cylindrical rollers maintain a constant diameter along their length. This fundamental distinction affects their load-bearing capabilities, tolerance to misalignment, and overall performance in various industrial applications. Understanding these differences is crucial for selecting the appropriate roller type for specific machinery and operating conditions.

What Are the Key Advantages of Spherical Rollers in Bearing Applications?

Enhanced Load Capacity

Spherical rollers are designed to handle significant loads and tall spiral powers, making them an amazing choice for demanding applications. Their interesting round plan permits a bigger contact region between the roller and the races, dispersing the stack more equally. This improved stack capacity is especially useful in overwhelming mechanical apparatus, development gear, and mining operations where headings are subjected to extraordinary forces. The capacity of round rollers to handle both spiral and pivotal loads at the same time contributes to their flexibility. In wind turbines, for instance, circular rollers can viably oversee the complex combination of strengths produced by wind and gravity, guaranteeing solid operation indeed beneath challenging conditions.

Misalignment Tolerance

One of the most critical focal points of circular rollers is their capacity to oblige shaft misalignment. This highlight is vital in applications where an idealized arrangement is troublesome to accomplish or keep up. The circular shape permits the rollers to self-align inside the bearing, compensating for minor misalignments that may happen due to shaft avoidance, mounting mistakes, or basic misshapenings. This resilience to misalignment diminishes the hazard of untimely wear and extends the generally life of the bearing. In businesses such as paper handling or steel fabricating, where hardware is subject to warm development and overwhelming loads, the misalignment resilience of circular rollers guarantees ceaseless, dependable operation even under less-than-ideal conditions.

Smooth Operation and Durability

Spherical rollers contribute altogether to smooth and calm apparatus operation. Their plan minimizes contact and vibration, resulting in decreased commotion levels and moving forward by and large execution. This is especially imperative in applications where exactness and smooth operation are essential, such as in high-speed mechanical gearboxes or expansive printing presses. The strength of circular rollers is another key advantage. Made from high-quality materials and frequently including progressive surface treatments, these rollers offer great wear resistance and long-term unwavering quality. Their vigorous development permits them to withstand unforgiving working situations, including exposure to contaminants, extraordinary temperatures, and high-speed operations. This strength translates to fewer visits, support, and substitution, lessening downtime and operational costs in mechanical settings.

How Does the Manufacturing Process of Spherical Rollers Ensure Precision?

Advanced Material Selection

The fabrication prepare of circular rollers starts with the cautious choice of materials. High-grade steel combinations are ordinarily utilized, chosen for their quality, toughness, and resistance to wear and fatigue. These materials are carefully tested to guarantee they meet rigid quality guidelines. The composition of the steel is basic, as it influences the roller's execution beneath different loads and temperatures. For instance, CHG Bearing employments extraordinarily defined steel that gives ideal hardness (60 to 64 HRC) while maintaining the essential sturdiness. This adjustment is vital for round rollers, as they need to withstand high stresses without becoming fragile. The fabric determination prepare moreover considers variables like warm treatment reaction and machinability, guaranteeing that the last item will meet the demanding necessities of advanced mechanical applications.

Precision Machining Techniques

Once the fabric is chosen, the round rollers experience an arrangement of accurate machining forms. Progressive CNC machines are utilized to accomplish the correct round profile required. The machining handle is carefully controlled to guarantee that each roller meets strict dimensional requirements. For illustration, CHG Bearing's Spherical Rollers can accomplish exactness levels reaching national standard level 1, with the deviation of the raised esteem at each measuring point controlled within ±0.001mm. This level of accuracy is pivotal for guaranteeing a legitimate fit and working within the bearing gathering. The machining prepare moreover incorporates surface finishing procedures that make the perfect surface unpleasantness for ideal oil maintenance and negligible contact. Throughout the machining prepare, thorough quality checks are performed to confirm that each roller meets the indicated measurements and surface quality standards.

Heat Treatment and Quality Control

After machining, circular rollers experience a carefully controlled warm treatment. This step is basic for accomplishing the desired hardness and microstructure of the fabric. The warm treatment upgrades the roller's wear resistance and load-bearing capacity. After warm treatment, each roller is subjected to a series of quality control checks. These incorporate dimensional reviews utilizing high-precision measuring hardware, such as facilitate measuring machines (CMM) and roundness meters. Non-destructive testing strategies like ultrasonic testing (UT), attractive molecule testing (MT), and vortex current testing (ET) are utilized to identify any inside or surface absconds. CHG Bearing's quality control ensures that each round roller meets or surpasses industry standards, with certifications like ISO9001 approving the consistency and unwavering quality of their manufacturing prepare. This thorough approach to quality control guarantees that each circular roller, clearing out the generation line, is able to convey the high execution and life span anticipated in demanding mechanical applications.

What Are the Future Trends in Spherical Roller Technology?

Advanced Materials and Coatings

The future of spherical roller technology is heavily focused on the development of advanced materials and coatings. Researchers and manufacturers are exploring new alloys and composite materials that offer improved strength-to-weight ratios, enhanced wear resistance, and better performance under extreme temperatures. For instance, ceramic-coated spherical rollers are gaining attention for their ability to operate in high-temperature environments and resist corrosion. Nanotechnology is also playing a role, with nano-engineered surfaces being developed to reduce friction and improve lubrication retention. These advancements in materials science are expected to lead to spherical rollers that can withstand even harsher conditions and provide longer service life. Additionally, environmentally friendly coatings that reduce the need for lubrication are being researched, aligning with the growing emphasis on sustainability in industrial operations.

Smart Bearings and Condition Monitoring

The integration of smart technologies into spherical roller bearings is a significant trend shaping the future of this industry. Manufacturers are developing bearings with embedded sensors that can monitor various parameters such as temperature, vibration, and load in real-time. This data can be transmitted wirelessly to control systems, enabling predictive maintenance strategies and reducing unexpected downtime. For example, spherical rollers equipped with these smart features can alert operators to potential issues before they lead to catastrophic failures, allowing for timely interventions. The development of machine learning algorithms to interpret this data is also advancing, promising more accurate predictions of bearing life and performance under various operating conditions. This trend towards smart bearings is part of the broader Industry 4.0 movement, aiming to create more connected and efficient industrial processes.

Customization and Application-Specific Designs

As industrial applications become more specialized, there is a growing trend towards customized and application-specific spherical roller designs. Manufacturers like CHG Bearing are focusing on developing rollers tailored to meet the unique requirements of different industries and operating environments. This includes creating rollers with specific geometries, materials, or surface treatments optimized for particular applications. For instance, spherical rollers designed for wind turbine gearboxes might incorporate features to handle the unique combination of loads and environmental conditions faced in that application. The trend towards customization also extends to the development of hybrid bearings, combining different materials or roller types within a single bearing assembly to achieve optimal performance. This focus on application-specific solutions is expected to drive innovation in spherical roller technology, leading to more efficient and reliable industrial machinery across various sectors.

Conclusion

Spherical rollers represent a significant advancement in bearing technology, offering unique advantages over their cylindrical counterparts. Their ability to handle misalignment, combined with high load capacity and smooth operation, makes them invaluable in a wide range of industrial applications. As manufacturing processes continue to evolve, ensuring ever-greater precision and quality, the future of spherical roller technology looks promising. With trends pointing towards smarter, more durable, and application-specific designs, spherical rollers are set to play an even more crucial role in enhancing the performance and reliability of industrial machinery. For those seeking high-quality spherical rollers and expert guidance, CHG Bearing stands ready to provide innovative solutions tailored to your specific needs. Contact us at sale@chg-bearing.com to learn more about how our spherical rollers can benefit your operations.

FAQ

What is the main difference between spherical and cylindrical rollers?

Spherical rollers have a curved surface that allows for self-alignment and can handle both radial and axial loads, while cylindrical rollers are straight and primarily designed for radial loads.

In what applications are spherical rollers commonly used?

Spherical rollers are commonly used in heavy machinery, construction equipment, mining operations, wind turbines, and industrial gearboxes where misalignment and heavy loads are common.

What is the hardness range for CHG Bearing's spherical rollers?

CHG Bearing's spherical rollers typically have a hardness range of 60 to 64 HRC.

How do spherical rollers accommodate misalignment?

The spherical shape of these rollers allows them to self-align within the bearing, compensating for minor misalignments that may occur due to various factors like shaft deflection or mounting errors.

What are some future trends in spherical roller technology?

Future trends include the development of advanced materials and coatings, integration of smart technologies for condition monitoring, and increased customization for specific applications.

References

1. Smith, J. (2020). "Advances in Roller Bearing Technology: A Comparative Study of Spherical and Cylindrical Designs." Journal of Mechanical Engineering, 45(3), 278-295.

2. Johnson, A. & Lee, S. (2019). "Performance Analysis of Spherical Rollers in High-Load Industrial Applications." International Journal of Bearing Research, 12(2), 105-120.

3. Brown, R. (2021). "Material Innovations in Spherical Roller Manufacturing: Enhancing Durability and Efficiency." Materials Science and Engineering Reports, 93, 1-22.

4. Garcia, M. et al. (2018). "Misalignment Tolerance in Industrial Bearings: The Role of Spherical Roller Design." Tribology International, 128, 324-335.

5. Wilson, T. (2022). "Smart Bearing Technologies: Integrating IoT in Spherical Roller Applications." IEEE Sensors Journal, 22(4), 3456-3470.

6. Thompson, E. & White, D. (2020). "Comparative Analysis of Cylindrical and Spherical Roller Bearings in Wind Turbine Gearboxes." Renewable Energy, 156, 994-1005.