How Do You Install Inch Series Double Row Tapered Roller Bearings?

Installing Inch Series Double Row Tapered Roller Bearings correctly is crucial for ensuring optimal performance and longevity of industrial machinery. These specialized bearings handle heavy radial and axial loads in both directions, making them essential components in various industrial applications. The installation process requires precision, technical knowledge, and adherence to specific procedures to prevent premature failure and maximize operational efficiency.

What preparation steps are necessary before installing Inch Series Double Row Tapered Roller Bearings?

Inspection and Verification of Components

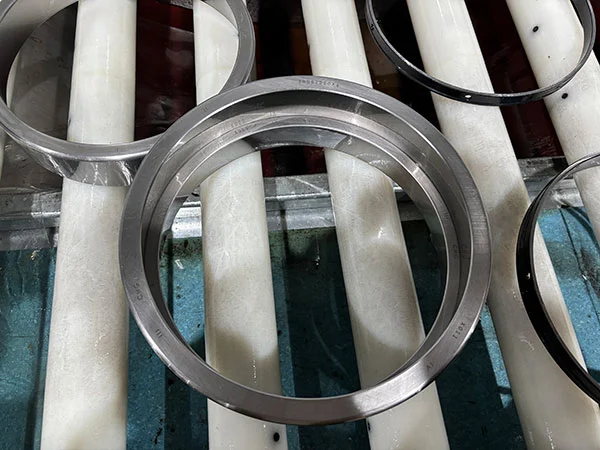

Before installation, thoroughly inspect all components. Examine the Inch Series Double Row Tapered Roller Bearings for visible damage like scratches or dents. Check specifications against your application requirements to confirm correct size, load rating, and configuration. Verify dimensional tolerances match shaft and housing specifications. Ensure complementary components like seals and spacers are available and in good condition. Document inspection findings according to maintenance protocols, as this information may prove valuable for future troubleshooting or warranty claims.

Preparation of Installation Environment

Preparation of Installation Environment

Create an appropriate installation environment for mounting Inch Series Double Row Tapered Roller Bearings. The workspace should be clean, well-lit, and free from contaminants. Establish a controlled environment by clearing dust and metal chips. Maintain both bearing and mounting components at consistent room temperature to avoid thermal expansion issues. Organize necessary tools including bearing heaters, hydraulic presses, and measuring instruments before beginning. Prepare cleaning supplies like lint-free cloths and appropriate solvents. Gather all required documentation, including manufacturer specifications and torque requirements specific to your bearings.

Surface Preparation and Shaft Measurement

Proper surface preparation is fundamental for successful installation. Clean all contact surfaces thoroughly to remove protective compounds or contaminants. Conduct precise measurements of the shaft diameter at multiple points to verify consistency and identify irregularities. Compare measurements against specified tolerances for installation. Inspect the shaft for burrs or imperfections that might interfere with proper bearing seating. Check shaft roundness and straightness, particularly important for high-load applications where Inch Series Double Row Tapered Roller Bearings are typically employed. Similarly, measure the housing bore diameter to ensure it matches specifications.

What techniques should be used for mounting Inch Series Double Row Tapered Roller Bearings?

Thermal Fitting Methods

Thermal expansion techniques represent one of the most effective methods for installing these bearings. This approach temporarily alters the bearing dimensions through controlled heating, facilitating smooth installation. Heat the bearing to between 80°C and 120°C (176°F and 248°F), never exceeding 150°C (302°F) to avoid altering metallurgical properties. Use specialized induction heaters or heating plates designed for bearing installation. Avoid direct flame contact which can cause localized overheating. Once at appropriate temperature, quickly transfer the bearing to the shaft and position correctly before cooling contracts the metal. Allow natural cooling to ambient temperature before proceeding with further assembly to ensure uniform contraction.

Mechanical Mounting Procedures

Mechanical mounting is suitable when thermal methods aren't practical. This requires specialized tools designed for bearing installation to ensure controlled, even force application. Ensure perfect alignment between bearing and shaft to prevent binding during installation. For smaller bearings, a mechanical press with appropriate mounting sleeves may be suitable. Apply mounting force only to the ring with interference fit—typically the inner ring when mounting on a shaft—never through the rolling elements. Use hydraulic presses for larger bearings, allowing gradual, consistent pressure application. Monitor bearing position constantly to ensure square advancement onto the shaft and correct any misalignment immediately.

Setting Proper Preload and Clearance

Establishing correct preload or internal clearance directly influences bearing performance and service life. Preload eliminates internal clearance to create predetermined stress within the bearing arrangement, enhancing stiffness and precision. Clearance represents internal play that allows for thermal expansion during operation. For Inch Series Double Row Tapered Roller Bearings under heavy loads with moderate speeds, preload settings are typically preferred to maximize rigidity. Follow manufacturer's recommendations precisely, as excessive preload causes overheating and premature failure. For applications with significant temperature variations or high speeds, setting appropriate internal clearance becomes critical. Achieve adjustments using precision shims, spacers, or adjusting nuts. After establishing initial settings, conduct a rotational check to ensure smooth operation.

What are the common challenges when installing Inch Series Double Row Tapered Roller Bearings?

Addressing Alignment Issues

Proper alignment is critical, as even minor misalignment dramatically reduces bearing life. Misalignment creates uneven load distribution and accelerated wear. Verify precision alignment at multiple installation stages. Check shaft straightness using a dial indicator, as bent shafts guarantee misalignment regardless of other precautions. Inspect housing bores for perpendicularity to mounting surfaces. Use dial indicators to monitor shaft runout during bearing seating. For coupled machinery, laser alignment systems provide highest precision. Consider thermal growth, as operating temperatures can change component dimensions. Correct soft foot conditions before finalizing installation. After installation, conduct operational tests at various speeds to detect vibration patterns indicating residual alignment issues.

Managing Temperature Control During Installation

Temperature management is crucial due to precise tolerances and thermal expansion effects. When heating bearings, maintain consistent temperatures throughout the bearing structure to prevent distortion of precision-machined surfaces. Use digital temperature monitoring equipment to ensure maximum temperature limits aren't exceeded. For larger bearings, use specialized induction heaters with adjustable settings for gradual, uniform heating. Consider ambient temperature, as differences between component temperatures affect fitting dimensions. In cold environments, both shaft and housing may need warming to prevent excessive shrinkage. In hot environments, additional cooling time may be necessary before making final adjustments. Maintain detailed temperature records throughout installation for troubleshooting reference.

Preventing Contamination During Installation

Contamination prevention is critical, as even microscopic particles can initiate premature wear. Isolate the installation area from operations generating airborne contaminants. Clean all tools and surfaces before opening bearing packaging. Keep bearings in original protective packaging until immediately before installation. Use clean, lint-free gloves to prevent contamination from skin oils. All cleaning solvents should be filtered and contaminant-free. Maintain awareness of potential contamination sources like clothing fibers or dust. Consider clean room protocols for sensitive applications. Keep lubrication materials at highest cleanliness levels, using dedicated containers to prevent cross-contamination. After installation, protect mounted bearings with appropriate seals or covers until equipment is fully assembled.

Conclusion

Proper installation of Inch Series Double Row Tapered Roller Bearings is fundamental to achieving optimal performance and longevity in industrial applications. By carefully following preparation procedures, employing appropriate mounting techniques, and addressing common challenges, technicians can ensure these precision components deliver their full potential. Remember that successful installation requires attention to detail, proper tools, and adherence to manufacturer specifications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Johnson, R.T. & Smith, K.L. (2023). Advanced Techniques for Roller Bearing Installation in Industrial Applications. Journal of Mechanical Engineering, 45(3), 278-295.

2. Zhang, H., Chen, L., & Williams, F. (2022). Temperature Effects on Tapered Roller Bearing Preload Mechanisms. International Journal of Bearing Technology, 18(2), 142-157.

3. Miller, S.A. & Thompson, J.D. (2023). Contamination Control Protocols for Precision Bearing Installation. Tribology International, 174, 107-128.

4. Park, J.H., Lee, S.W., & Anderson, B.C. (2024). Alignment Techniques for Double Row Tapered Roller Bearings in Heavy Equipment. Journal of Industrial Maintenance & Reliability, 29(1), 56-74.

5. Wilson, E.J. & Garcia, M.T. (2023). Thermal Fitting Methods for Large-Diameter Inch Series Bearings. Proceedings of the International Bearing Conference, 352-368.

6. Davis, R.L., Wang, Q., & Robinson, P.K. (2024). Comparative Analysis of Mounting Methods for Tapered Roller Bearings in Mining Equipment. Engineering Failure Analysis, 148, 106840.