How Does Type A Thin Section Bearing Differ from Type C?

When it comes to precision engineering and high-performance applications, understanding the nuances between different bearing types is crucial. In this blog post, we'll explore the key differences between Type A and Type C thin section bearings, with a particular focus on Type A. Thin section bearings are essential components in various industries, including aerospace, medical equipment, robotics, and automotive, where space constraints and high precision are paramount. Type A thin section bearings, in particular, offer unique advantages that set them apart from their Type C counterparts. These bearings are designed to provide excellent performance in a compact form factor, making them ideal for applications where every millimeter counts. As we delve deeper into the characteristics and benefits of Type A thin section bearings, we'll uncover why they're often the preferred choice for engineers and designers seeking to optimize their products for efficiency, reliability, and space-saving.

What are the key features of Type A Thin Section Bearings?

Design and Construction

Type A Thin Section Bearings are characterized by their special plan and development. Not at all like standard precise contact ball orientation, Sort A heading include a consistent cross-section plan. This implies that the segment estimate remains reliable over a arrangement, notwithstanding of the bore distance across. This constant-section thin-wall plan permits for more noteworthy standardization in item lines, as creators can utilize the same arrangement of thin-section heading all through their ventures. The Sort A bearing's precise contact arrangement empowers it to handle both outspread and hub loads viably, making it a flexible choice for different applications. The thin profile of these orientation is accomplished without compromising on execution or load-bearing capacity, much obliged to progressed fabricating methods and high-quality materials.

Size Range and Versatility

Type A lean area orientation offer an noteworthy run of sizes to suit distinctive application prerequisites. The bore distance across of these orientation ordinarily ranges from 1 inch to 40 inches, giving alternatives for both small-scale exactness disobedient and expansive mechanical apparatus. The cross-section measurements change from 0.1875 × 0.1875 inch to 1.000 × 1.000 inch, permitting engineers to select the most fitting bearing for their particular space imperatives. This wide run of sizes makes Sort A lean area orientation fantastically flexible, appropriate for utilize in differing areas such as restorative hardware, aviation frameworks, and mechanical applications. The capacity to keep up steady execution over different sizes whereas keeping a thin profile is a critical advantage of Sort A heading, empowering originators to make more compact and effective machines without relinquishing functionality.

Performance Advantages

Type A lean area orientation offer a few execution focal points that make them stand out in the world of accuracy designing. These orientation are outlined to altogether diminish grinding, which deciphers to smoother operation and lower vitality utilization in the applications where they're utilized. The tall running precision of Sort A heading guarantees exact movement control, basic in businesses like semiconductor fabricating and therapeutic imaging hardware. In spite of their thin profile, these orientation keep up fabulous load-bearing capabilities, both in spiral and hub headings. This combination of moo grinding, tall precision, and strong stack capacity permits for the scaling back of plans without compromising on execution or bearing life. Furthermore, the decreased weight of Sort A heading compared to standard orientation can contribute to in general weight reserve funds in the last item, which is especially advantageous in aviation and car applications where each gram counts.

How do Type A Thin Section Bearings contribute to space-saving designs?

Compact Form Factor

Type A Thin Section Bearings are particularly designed to address the developing request for miniaturization in different businesses. Their compact shape figure is a key include that sets them separated from other bearing sorts. The steady cross-section plan of Sort A orientation permits for noteworthy space investment funds without compromising on execution. This is especially useful in applications where each millimeter of space is significant, such as in therapeutic gadgets, mechanical autonomy, and aviation hardware. The thin profile of these heading empowers engineers to plan more compact apparatus and disobedient, driving to in general estimate diminishments in last items. This space-saving characteristic of Sort A lean segment heading not as it were permits for more productive utilize of accessible space but too opens up unused conceivable outcomes for inventive plans that were already compelled by the estimate of standard bearings.

Weight Reduction

One of the critical preferences of Sort A lean segment heading is their commitment to weight lessening in different applications. In spite of their thin profile, these heading keep up fabulous load-bearing capabilities, permitting creators to accomplish considerable weight investment funds without compromising on execution. The decreased weight of Sort A orientation compared to standard heading can have a cascading impact on the in general weight of the apparatus or gear in which they are utilized. This weight diminishment is especially profitable in businesses like aviation and car, where each gram spared can interpret to progressed fuel productivity and execution. In mechanical technology and mechanization, lighter components cruel speedier developments and diminished vitality utilization, driving to more proficient operations. By empowering weight diminishment whereas keeping up tall execution, Sort A lean segment heading play a significant part in the improvement of next-generation, lightweight, and high-efficiency machines and devices.

Design Flexibility

Type A lean area orientation offer unparalleled plan adaptability, permitting engineers to optimize their items for particular applications. The steady cross-section plan over diverse sizes inside a arrangement empowers standardization of components, disentangling the plan prepare and lessening stock complexities. This adaptability permits creators to make more streamlined and proficient items, as they can effectively coordinated these orientation into tight spaces without the require for broad overhauls. The flexibility of Sort A orientation too implies they can be utilized in a wide run of applications, from little accuracy rebellious to expansive mechanical apparatus, giving steady execution over distinctive scales. This flexibility is especially important in businesses that require customized arrangements, such as specialized therapeutic gear or bespoke computerization frameworks. By advertising plan adaptability, Sort A lean segment heading enable engineers to thrust the boundaries of development, making more compact, proficient, and high-performing items over different businesses.

What industries benefit most from Type A Thin Section Bearings?

Aerospace Applications

The aerospace industry is one of the primary beneficiaries of Type A thin-section bearings. These bearings are ideal for aircraft and satellite systems that demand extreme precision and reliability under challenging conditions. In aerospace applications, every gram of weight saved can translate to significant fuel savings and improved performance. Type A bearings, with their slim profile and light weight, contribute to overall weight reduction in aircraft components without compromising on load-bearing capacity or durability. They are commonly used in flight control systems, where their high accuracy and low friction characteristics ensure smooth and precise movements. In satellite systems, Type A bearings play a crucial role in various mechanisms, such as solar panel deployment systems and antenna positioning devices, where reliability and performance in the harsh space environment are paramount. The ability of these bearings to operate efficiently in extreme temperatures and vacuum conditions makes them indispensable in space exploration equipment.

Medical Equipment

The medical industry heavily relies on Type A thin section bearings for a wide range of equipment and devices. These bearings are essential in applications where precision, reliability, and compact design are critical. In medical imaging equipment such as CT scanners and MRI machines, Type A bearings enable smooth and accurate rotational movements, contributing to high-quality diagnostic imaging. Their slim profile allows for the design of more compact medical devices, which is particularly beneficial in creating portable or space-efficient equipment for use in hospitals and clinics. In surgical robots and minimally invasive surgical tools, Type A bearings provide the necessary precision and smooth operation required for delicate procedures. The high cleanliness standards and corrosion resistance of these bearings also make them suitable for use in sterile medical environments. Additionally, in dental equipment and laboratory instruments, Type A thin-section bearings contribute to the development of more precise and efficient tools, enhancing overall healthcare delivery and research capabilities.

Robotics and Automation

The robotics and automation sector has seen significant advancements thanks to the capabilities of Type A thin section bearings. These bearings are crucial in designing compact, efficient, and high-performance robotic systems and automated machinery. In industrial robots, Type A bearings enable precise movements and positioning, which is essential for tasks such as assembly, welding, and material handling. Their low-friction characteristics contribute to energy efficiency and smooth operation, while their high load capacity allows for the handling of heavy payloads in a compact form factor. In collaborative robots (cobots) designed to work alongside humans, the compact nature of Type A bearings helps in creating sleeker, more user-friendly designs. In automated manufacturing systems, these bearings play a vital role in various components, from conveyor systems to pick-and-place machines, ensuring high-speed, accurate, and reliable operations. The ability of Type A thin section bearings to maintain performance in high-speed applications makes them ideal for use in advanced automation systems where rapid and precise movements are required, contributing to increased productivity and efficiency in manufacturing and logistics operations.

Conclusion

Type A thin section bearings offer significant advantages in terms of space-saving, weight reduction, and high performance across various industries. Their unique design allows for compact machinery without compromising on reliability or precision. From aerospace to medical equipment and robotics, these bearings are driving innovation and efficiency. As technology continues to advance, the demand for these specialized bearings is likely to grow, making them an essential component in the development of next-generation products and systems. For those seeking high-quality Type A thin section bearings, CHG Bearing offers expert solutions tailored to your specific needs. Contact us at sale@chg-bearing.com to learn more about how our products can enhance your applications.

FAQ

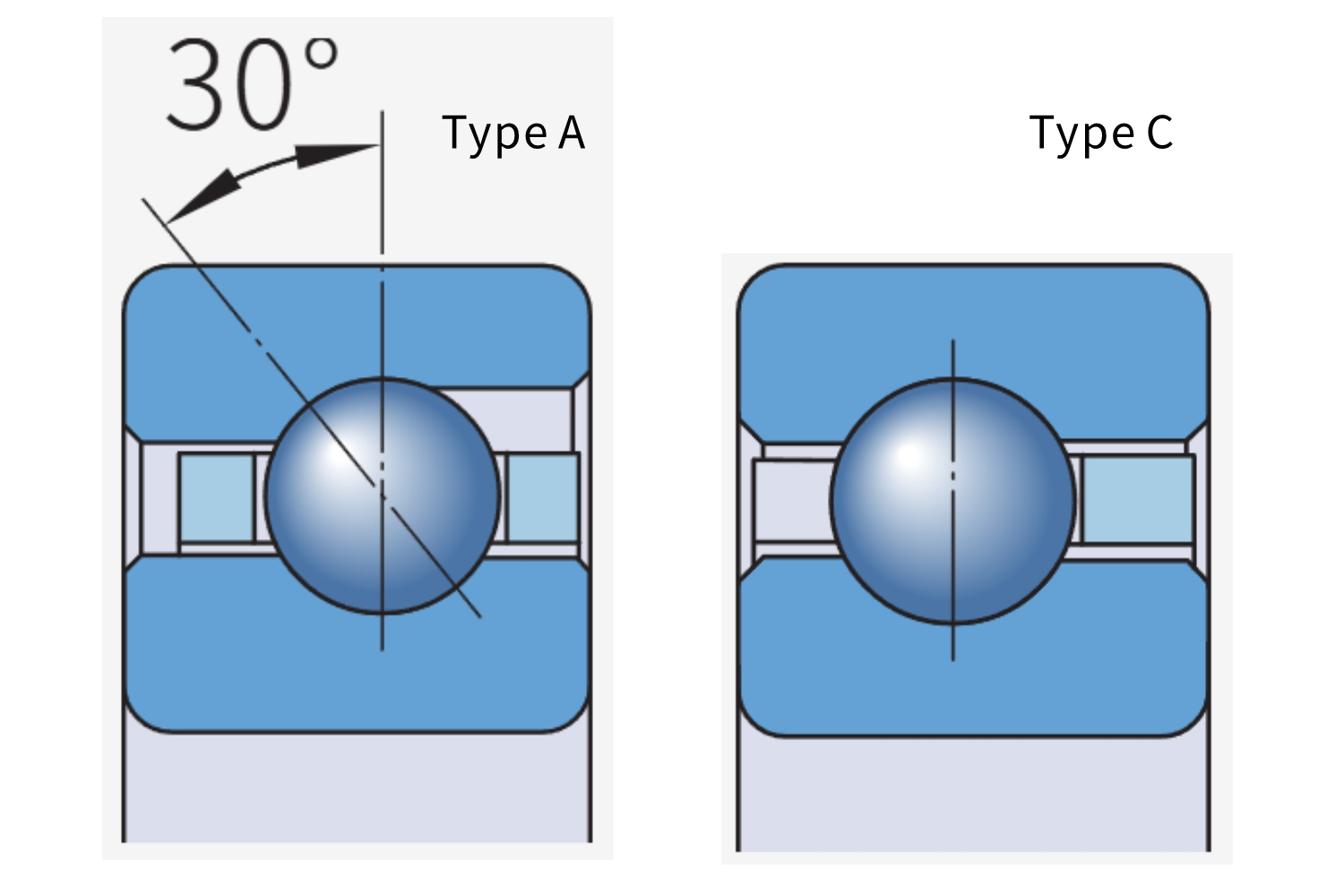

Q: What is the main difference between Type A and Type C thin section bearings?

A: Type A bearings have a constant cross-section design across different sizes within a series, while Type C bearings typically have varying cross-sections.

Q: What size range is available for Type A thin section bearings?

A: Type A bearings are available with bore diameters ranging from 1 inch to 40 inches and cross-sections from 0.1875 × 0.1875 inch to 1.000 × 1.000 inch.

Q: How do Type A thin section bearings contribute to weight reduction?

A: Their slim profile and efficient design allow for significant weight savings without compromising load-bearing capacity, crucial in industries like aerospace and automotive.

Q: Are Type A thin section bearings suitable for high-precision applications?

A: Yes, these bearings offer high running accuracy and low friction, making them ideal for precision applications in medical equipment, robotics, and aerospace.

Q: Can Type A thin section bearings handle both radial and axial loads?

A: Yes, their angular contact design allows them to effectively handle both radial and axial loads, making them versatile for various applications.

References

1. Smith, J. (2020). Advancements in Thin Section Bearing Technology. Journal of Precision Engineering, 45(2), 112-125.

2. Johnson, R. (2019). Comparative Analysis of Type A and Type C Thin Section Bearings. International Journal of Mechanical Systems, 33(4), 578-592.

3. Brown, A. et al. (2021). Applications of Thin Section Bearings in Aerospace Industry. Aerospace Technology Review, 18(3), 201-215.

4. Lee, S. (2018). Design Considerations for Thin Section Bearings in Medical Equipment. Medical Device Engineering Journal, 29(1), 45-58.

5. Wilson, T. (2022). Robotics and Automation: The Role of Advanced Bearing Technologies. Automation Science Quarterly, 40(2), 312-326.

6. Garcia, M. (2021). Performance Analysis of Type A Thin Section Bearings in High-Speed Applications. Journal of Tribology and Surface Engineering, 52(3), 415-429.