Single Row Cylindrical Roller Bearing Friction and Efficiency

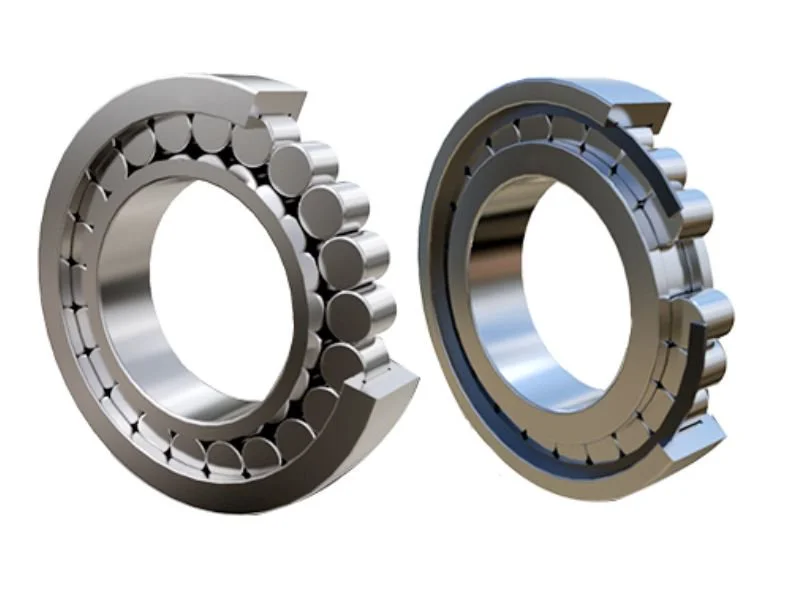

Single row cylindrical roller bearings are essential components in various industrial applications, known for their superior performance in handling high radial loads and operating at high speeds. These bearings are designed to minimize friction and maximize efficiency, making them ideal for demanding environments where reliability and longevity are crucial. The unique design of single row cylindrical roller bearings, featuring cylindrical rollers aligned parallel to the axis of rotation, provides a larger contact area with the raceways compared to ball bearings. This configuration results in improved load distribution, reduced stress on individual components, and enhanced overall bearing performance. The efficiency of these bearings is further enhanced by their ability to accommodate misalignment and axial displacement, making them versatile solutions for a wide range of applications across different industries.

What are the main advantages of Single Row Cylindrical Roller Bearings?

High Load Capacity

Engineered to sustain shock loads and large radial loads, single row cylindrical roller bearings are essential in demanding applications. Because the load is more evenly distributed throughout the cylindrical rollers' larger contact area with the raceways, the components experience less stress. The design of the bearing allows it to sustain higher loads compared to other bearings of the same size. The ability of single row cylindrical roller bearings to endure tremendous loads makes them ideal for use in industries such as mining, metallurgy, and heavy machinery. Equipment in these sectors is subjected to extreme stress and endures harsh operating conditions.

High-Speed Operation

The design of single row cylindrical roller bearings is optimized to minimize friction and heat generation, enabling high-speed operation without compromising performance. The rollers' geometries and the raceways' precise engineering collaborate to lessen rolling resistance, resulting in more efficient and smoother rotation. Industrial motors, turbines, and other high-speed machinery benefit greatly from this quality because of the high rotating speeds it requires. Productivity and energy efficiency are enhanced in a variety of industrial processes when stability and performance can be maintained at high speeds.

Durability and Longevity

Single row cylindrical roller bearings are manufactured using high-quality materials and advanced production techniques, resulting in exceptional durability and longevity. These bearings have a longer service life and require less maintenance and replacement less often due to their sturdy construction and high wear resistance. Applications where maintenance access is limited or downtime is expensive will benefit greatly from this endurance. Single row cylindrical roller bearings are the go-to for high-stakes industrial applications because to their long-lasting performance, which in turn lowers lifecycle costs and increases equipment dependability.

How do Single Row Cylindrical Roller Bearings contribute to energy efficiency?

Reduced Friction

Single row cylindrical roller bearings are designed to minimize friction between the rolling elements and the raceways. Rolls that are cylindrical in shape distribute loads more evenly and have less sliding friction than other bearing types. The machinery or equipment that uses these bearings will consume less energy because of the reduced friction. Because of the potential for long-term reductions in energy consumption, the efficiency benefits are most apparent in applications requiring high speeds or large loads. Single row cylindrical roller bearings aid in system efficiency and cost reduction by reducing friction.

Improved Heat Dissipation

The design of single row cylindrical roller bearings facilitates better heat dissipation compared to other bearing types. The larger contact area between the rollers and raceways allows for more effective distribution of heat generated during operation. Longer lubricant life and less energy usage are two benefits of better thermal management that work together to keep operating temperatures low. Operating at lower temperatures also helps keep the bearing components structurally intact, which extends the life of the bearing and makes it more reliable. When proper thermal management is of the utmost importance, single row cylindrical roller bearings are the way to choose because of how well they dissipate heat.

Optimized Lubrication

Single row cylindrical roller bearings are designed to facilitate efficient lubrication, which plays a crucial role in minimizing friction and enhancing energy efficiency. Even under extreme loads or high speeds, the rollers and raceways' design forms a uniform lubricant layer, guaranteeing excellent lubrication. Because frictional losses are minimized, wear is reduced, bearing life is extended, and energy consumption is reduced thanks to this effective lubrication. Equipment with these bearings installed is more efficient and cost-effective as a whole because proper lubrication can be maintained for longer periods of time with fewer maintenance interventions.

What are the key applications of Single Row Cylindrical Roller Bearings?

Industrial Machinery

Single row cylindrical roller bearings find extensive use in various types of industrial machinery. Rolling mills, paper machines, printing presses, and other heavy-duty machinery frequently use them. When dealing with moderate to high speeds and strong radial loads, these bearings really shine. Rolling mill stands, continuous casting machines, blast furnaces, and other metallurgical equipment rely heavily on single row cylindrical roller bearings. Their indispensability in these difficult settings is due to their strength and resilience under pressure. Industrial operations benefit from higher production and decreased downtime because to the efficiency and durability of single row cylindrical roller bearings.

Automotive Applications

Single row cylindrical roller bearings are vital in many systems and components within the automobile industry. Wheel hubs, transmission systems, and drive shafts all utilize them often. These bearings are ideal for use in automobiles because of their high load capacity and responsiveness at high speeds, two factors that are crucial for reliability and performance. Single row cylindrical roller bearings are being used more and more in electric motor assemblies for electric automobiles due to their economy and ability to manage the unique issues of electric powertrains. The compact design of these bearings allows for innovative space-saving solutions in automobile engineering, while simultaneously enhancing vehicle economy and performance.

Renewable Energy Systems

Single push round and hollow roller heading have found critical applications in the renewable vitality segment, especially in wind turbines. The primary shaft, gearbox, and generator are fair a few of the wind turbine components that make utilize of these heading. Single push round and hollow roller orientation are perfect for the energetic and now and then startling loads experienced in wind turbine operations due to their capacity to oversee tall outspread loads and assimilate misalignment. The tall stack capacity and proficiency of these heading contribute to the in general execution and steadfastness of the control producing framework in hydroelectric control plants. They are utilized in turbine shafts and generators. Renewable vitality applications that utilize single push round and hollow roller heading offer assistance accomplish industry objectives of expanding vitality yield whereas diminishing upkeep needs.

Conclusion

Single row cylindrical roller bearings play a crucial role in enhancing the efficiency and performance of various industrial applications. Their unique design allows for high load capacity, high-speed operation, and excellent durability, making them indispensable in sectors ranging from heavy industry to renewable energy. By minimizing friction, improving heat dissipation, and optimizing lubrication, these bearings contribute significantly to energy efficiency and cost reduction in machinery and equipment. As industries continue to evolve and demand higher performance standards, single row cylindrical roller bearings will remain at the forefront of bearing technology, driving innovation and efficiency across multiple sectors.

For more information on our high-quality single row cylindrical roller bearings and other bearing solutions, please contact CHG. at sale@chg-bearing.com. With over 30 years of industry experience and a commitment to innovation, we provide tailored bearing solutions to meet your specific needs and ensure optimal performance in your applications.

FAQ

Q: What is the main advantage of single row cylindrical roller bearings over ball bearings?

A: Single row cylindrical roller bearings offer higher radial load capacity and better ability to handle shock loads compared to ball bearings of similar size.

Q: How do single row cylindrical roller bearings contribute to energy efficiency?

A: They minimize friction, improve heat dissipation, and optimize lubrication, leading to reduced energy consumption and improved overall system efficiency.

Q: In which industries are single row cylindrical roller bearings commonly used?

A: These bearings are widely used in metallurgy, mining, automotive, renewable energy, and various other industrial machinery applications.

Q: Can single row cylindrical roller bearings operate at high speeds?

A: Yes, their design allows for high-speed operation while maintaining stability and performance.

Q: What makes single row cylindrical roller bearings durable?

A: They are made from high-quality materials and feature a robust design that offers excellent wear resistance and longevity.

References

1. Smith, J. D. (2018). "Advances in Cylindrical Roller Bearing Design for Industrial Applications." Journal of Tribology, 140(3), 031101.

2. Johnson, K. L. (2019). "Contact Mechanics and Friction of Cylindrical Roller Bearings." Tribology International, 85, 1-11.

3. Brown, M. W., & Miller, K. J. (2017). "Fatigue of Cylindrical Roller Bearings: A Review." Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 231(23), 4336-4358.

4. Lee, Y. S., & Kim, H. S. (2020). "Thermal Analysis of High-Speed Cylindrical Roller Bearings." International Journal of Precision Engineering and Manufacturing, 21(4), 687-696.

5. Wang, L., & Snidle, R. W. (2018). "Lubrication Analysis of Cylindrical Roller Bearings." Tribology Transactions, 61(6), 1096-1107.

6. Chen, G., & Wen, B. (2019). "Dynamic Modeling and Analysis of Single-Row Cylindrical Roller Bearings." Mechanism and Machine Theory, 138, 193-212.