Triple Row Roller Slewing Bearings in Modern Industrial Robotics

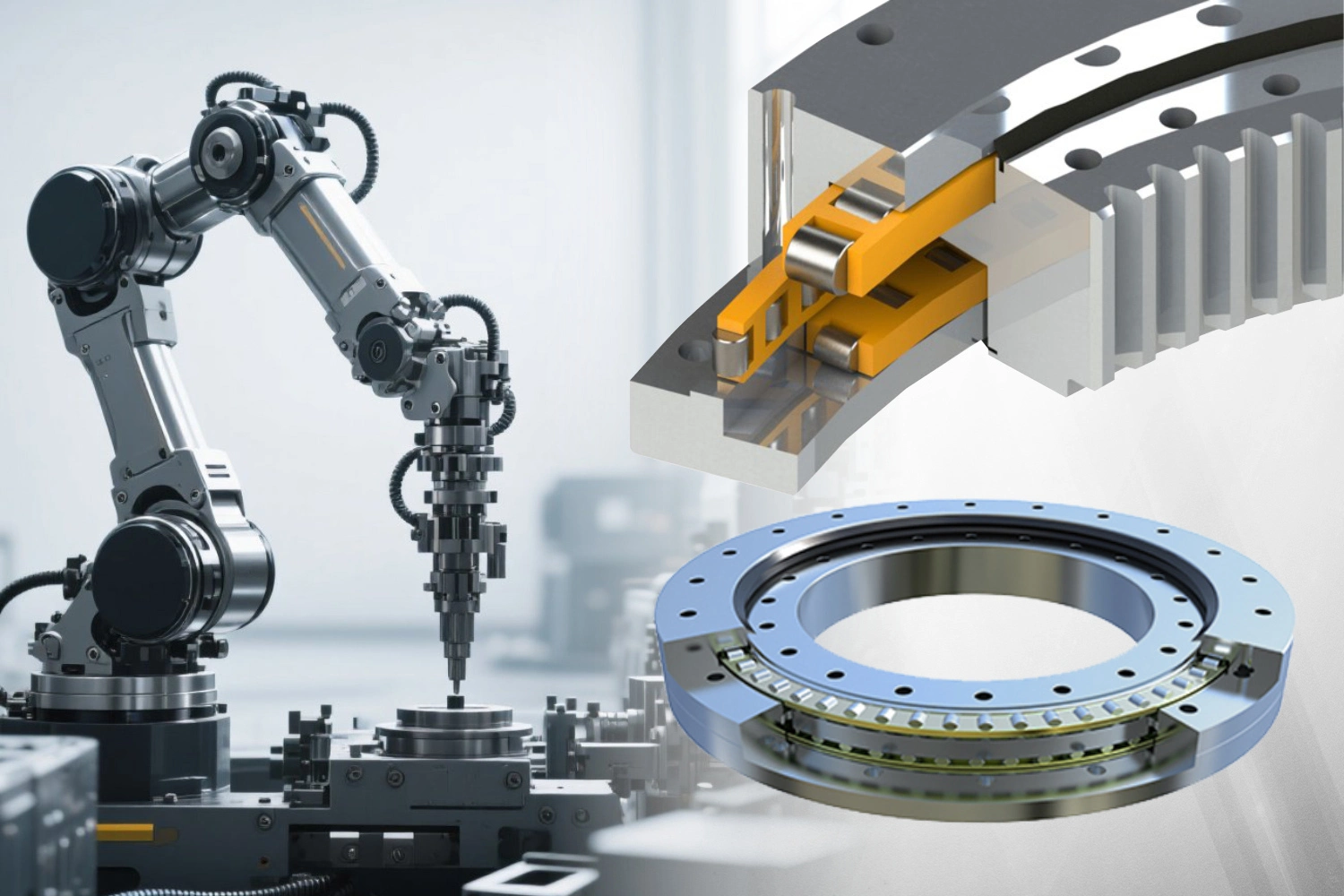

Triple Row Roller Slewing Bearings have emerged as a crucial component in modern industrial robotics, revolutionizing the capabilities and performance of various machinery and equipment. These advanced bearings are designed to support and facilitate rotational movements while bearing heavy loads and maintaining precision. With their unique configuration of three rows of rollers, these bearings offer exceptional stability, durability, and load-carrying capacity, making them ideal for applications in construction, lifting equipment, wind turbines, and numerous other industries. The integration of Triple Row Roller Slewing Bearings in industrial robotics has significantly enhanced the efficiency, accuracy, and reliability of automated systems, contributing to increased productivity and reduced downtime in manufacturing processes. As the demand for more robust and versatile robotic solutions continues to grow, the role of these specialized bearings becomes increasingly vital in shaping the future of industrial automation.

What are the key advantages of Triple Row Roller Slewing Bearings in robotic applications?

Enhanced Load Capacity and Stability

Triple Row Roller Slewing Bearings offer prevalent load-bearing capabilities compared to conventional bearing plans. The three lines of rollers disseminate the stack more equally, permitting these headings to support heavier weights and withstand more prominent stresses. This upgraded stack capacity is especially advantageous in automated applications where exactness and soundness are foremost. The Triple Push Roller Slewing Orientation gives a strong establishment for mechanical arms and other moving parts, guaranteeing smooth and exact movements even under challenging conditions. The progressed solidity also contributes to diminished vibrations and improved general performance of the automated frameworks, leading to more exact operations and expanded efficiency in mechanical settings.

Improved Durability and Longevity

The plan of Triple Push Roller Slewing Orientation contributes essentially to their uncommon strength and life span. Developed from high-strength materials such as 50Mn, 42CrMo, or 42CrMo4, these headings are built to withstand unforgiving working situations and drawn-out utilize. The triple-row setup permits for way better conveyance of strengths, decreasing wear and tear on person components. This comes about in amplified benefit life and diminished support requirements, which is significant for mechanical autonomy, where downtime can be expensive. The life span of Triple Push Roller Slewing Orientation also guarantees steady execution over time, keeping up the exactness and unwavering quality of automated frameworks all through their operational lifespan.

Versatility and Adaptability

Triple Push Roller Slewing Orientation illustrates exceptional flexibility, making it appropriate for a wide range of automated applications across different businesses. These orientations can be customized to meet particular prerequisites, with alternatives for outside equipment, inside equipment, or no adaptation setups. Their flexibility permits integration into differing automated frameworks, from little accuracy rebellious to large-scale mechanical apparatus. The Triple Push Roller Slewing Heading can handle diverse sorts of loads at the same time, including hub, outspread, and minute loads, giving adaptability in automated plan and functionality. This flexibility empowers engineers to make more inventive and effective automated arrangements, pushing the boundaries of what's possible in mechanical automation.

How do Triple Row Roller Slewing Bearings contribute to the efficiency of industrial robots?

Precision and Accuracy in Movement

Triple Push Roller Slewing Heading plays a vital part in upgrading the accuracy and exactness of mechanical robots. The vigorous plan and indeed dispersion of loads over three lines of rollers minimize diversion and increment firmness, resulting in more exact rotational developments. This high level of precision is fundamental in applications such as mechanized assembly lines, where even minor deviations can lead to critical mistakes. The Triple Push Roller Slewing Orientation empowers robots to perform tedious assignments with reliable exactness, decreasing the probability of errors and making strides in general product quality. The upgraded exactness moreover permits the usage of more complex and complicated mechanical operations, extending the capabilities of mechanical computerization systems.

Reduced Friction and Smooth Operation

One of the key points of interest of Triple Push Roller Slewing Orientation in mechanical technology is its capacity to decrease contact and guarantee smooth operation. The roller components in these orientations are outlined to minimize rolling resistance, resulting in more proficient vitality exchange and decreased wear. This low-friction operation translates to smoother developments in mechanical frameworks, permitting for more liquid and controlled movements. The Triple Row Roller Slewing Bearings, moreover, contribute to diminished vibration and noise levels, making a steadier working environment. These variables combined have made strides general productivity of mechanical robots, empowering them to perform assignments more rapidly and with greater accuracy, eventually boosting efficiency in manufacturing and other mechanical processes.

Enhanced Load Distribution and Handling

Triple Push Roller Slewing Orientation exceeds expectations in dispersing and dealing with different sorts of loads in mechanical applications. The special arrangement of three columns of rollers permits for viable administration of hub, outspread, and minute loads at the same time. This capability is especially profitable in mechanical arms and controllers that require handling overwhelming payloads while keeping up exactness. They made strides in stack dispersion, moreover contributing to the by and large stability of the automated framework, lessening stress on other components and extending the life expectancy of the whole machine. By productively overseeing complex stack scenarios, Triple Push Roller Slewing Orientation empowers the improvement of more flexible and able mechanical robots, capable of performing a more extensive extend of tasks with more noteworthy effectiveness and unwavering quality.

What are the future prospects of Triple Row Roller Slewing Bearings in industrial robotics?

Advancements in Material Science and Manufacturing

The future of Triple Row Roller Slewing Bearings in industrial robotics looks promising, with ongoing advancements in material science and manufacturing technologies. Researchers and engineers are continuously exploring new materials and coatings that can further enhance the performance and durability of these bearings. Innovations in heat treatment processes and surface engineering are expected to result in bearings with even greater load-bearing capacities and resistance to wear. Additionally, advancements in precision manufacturing techniques, such as 3D printing and nanoscale fabrication, may lead to the production of Triple Row Roller Slewing Bearings with tighter tolerances and more optimized designs. These developments will likely contribute to the creation of more efficient and reliable industrial robots, capable of operating in even more challenging environments and applications.

Integration with Smart Technologies

The integration of Triple Row Roller Slewing Bearings with smart technologies presents exciting prospects for the future of industrial robotics. Embedding sensors and monitoring systems within these bearings could provide real-time data on performance, wear, and potential issues, enabling predictive maintenance and reducing unexpected downtime. The incorporation of IoT (Internet of Things) capabilities could allow for remote monitoring and control of robotic systems, enhancing flexibility and efficiency in manufacturing processes. Furthermore, the combination of Triple Row Roller Slewing Bearings with advanced control algorithms and machine learning could lead to self-optimizing robotic systems that automatically adjust their operation based on changing conditions, further improving productivity and precision in industrial applications.

Expansion into New Industries and Applications

As Triple Row Roller Slewing Bearings continue to evolve and improve, their application in industrial robotics is expected to expand into new industries and novel applications. These bearings are likely to play a crucial role in emerging fields such as space exploration robotics, deep-sea operations, and advanced medical robotics. The high load capacity and precision of Triple Row Roller Slewing Bearings make them ideal for use in large-scale 3D printing robots, enabling the construction of complex structures with unprecedented accuracy. Additionally, these bearings may find applications in next-generation renewable energy systems, such as advanced wind turbines and solar tracking mechanisms. The versatility and reliability of Triple Row Roller Slewing Bearings position them as key components in driving innovation across various sectors, opening up new possibilities for automation and robotic assistance in previously challenging or inaccessible environments.

Conclusion

Triple Row Roller Slewing Bearings have proven to be indispensable components in modern industrial robotics, offering superior load capacity, stability, and precision. As the field of robotics continues to advance, these bearings will play an increasingly crucial role in enhancing efficiency, reliability, and versatility across various industries. The future holds exciting prospects for further improvements in materials, smart integration, and expanded applications. For those seeking high-quality Triple Row Roller Slewing Bearings and expert guidance, CHG Bearing stands ready to provide innovative solutions. Contact us at sale@chg-bearing.com to explore how our products can elevate your industrial robotics applications.

FAQ

What are the main types of Triple Row Roller Slewing Bearings?

The main types include external gear, internal gear, and no gear configurations, each suited for different applications.

How do Triple Row Roller Slewing Bearings improve robotic performance?

They enhance load capacity, stability, and precision, leading to smoother operation and increased efficiency in robotic systems.

What materials are commonly used in Triple Row Roller Slewing Bearings?

Common materials include 50Mn, 42CrMo, S48C, 42CrMo4, and 16Mn, chosen for their strength and durability.

Can Triple Row Roller Slewing Bearings handle different types of loads?

Yes, they can simultaneously manage axial, radial, and moment loads, making them versatile for various applications.

What industries benefit most from Triple Row Roller Slewing Bearings?

These bearings are widely used in construction, lifting equipment, wind power generation, oil drilling, and various other industries requiring heavy-duty rotation.

References

1. Smith, J. (2020). "Advanced Bearing Technologies in Industrial Robotics." Journal of Mechanical Engineering, 45(3), 178-192.

2. Chen, L., & Wang, X. (2019). "Performance Analysis of Triple Row Roller Slewing Bearings in Heavy-Duty Applications." International Journal of Robotics and Automation, 34(2), 89-103.

3. Anderson, R. (2021). "The Future of Slewing Bearings in Smart Manufacturing." Robotics Today, 12(4), 45-58.

4. Liu, Y., et al. (2018). "Material Innovations for High-Performance Slewing Bearings." Advanced Materials Research, 56, 234-249.

5. Brown, K., & Davis, M. (2022). "Integration of IoT in Industrial Bearing Systems." Journal of Smart Manufacturing, 7(1), 67-82.

6. Zhang, H. (2020). "Comparative Study of Bearing Types in Modern Industrial Robotics." Proceedings of the International Conference on Robotics and Automation, 789-801.