Unlocking Cost-Effective Solutions with Single Row Cylindrical Roller Bearings

Single row cylindrical roller bearings represent a cornerstone in modern industrial applications, offering an optimal balance of performance and cost-effectiveness. These precision-engineered components have revolutionized how industries approach their mechanical systems, providing reliable solutions for various operational challenges while maintaining economic efficiency. Let's explore the key aspects of these essential components and understand how they deliver value across different applications.

How Do Single Row Cylindrical Roller Bearings Maximize Load Capacity and Service Life?

The exceptional load-bearing capabilities of single row cylindrical roller bearings stem from their unique design characteristics. These bearings feature line contact between the rollers and raceways, providing superior radial load distribution compared to point contact found in ball bearings. This design enables them to handle significantly higher radial loads while maintaining optimal performance under high-speed conditions.

The roller geometry plays a crucial role in load capacity optimization. The length-to-diameter ratio of the rollers is carefully calculated to ensure maximum load capacity while minimizing friction and heat generation. Modern manufacturing techniques incorporate precise profiling of both rollers and raceways, which helps distribute loads more evenly and reduce stress concentrations at the roller ends. This feature significantly extends bearing service life by preventing premature wear and fatigue.

Furthermore, the cage design in these bearings ensures proper roller guidance and adequate lubrication distribution. Advanced cage materials and designs prevent roller skewing and maintain proper spacing, even under heavy loads and high speeds. This attention to detail in design and manufacturing results in bearings that can operate reliably for extended periods, reducing maintenance requirements and operational costs.

The separable design of these bearings also contributes to their longevity. During maintenance, components can be individually inspected and replaced if necessary, often extending the overall bearing life beyond that of non-separable alternatives. This feature proves particularly valuable in applications where downtime must be minimized and maintenance costs kept under control.

What Makes Single Row Cylindrical Roller Bearings Ideal for High-Speed Applications?

The suitability of single row cylindrical roller bearings for high-speed applications stems from several design features that work in concert to maintain stability and efficiency at elevated speeds. The roller guidance system, combined with precision-manufactured cages, ensures smooth operation even under challenging conditions.

One key factor is the bearing's ability to accommodate thermal expansion during high-speed operation. The design allows for slight axial movement of the roller elements relative to the raceways, preventing binding and excessive heat generation that could otherwise lead to premature failure. This feature is particularly important in applications where rapid temperature changes occur or where consistent high-speed operation is required.

The cage design plays a critical role in high-speed performance. Modern cages are engineered to minimize friction while providing optimal roller guidance. Materials selected for cage construction offer low friction coefficients and excellent wear resistance, ensuring reliable operation even under demanding conditions. Additionally, the cage design facilitates proper lubrication distribution, which is crucial for maintaining an adequate oil film at high speeds.

Advanced manufacturing techniques ensure that these bearings maintain precise internal clearances, which is essential for high-speed operation. The careful control of radial internal clearance helps prevent excessive heat generation while maintaining proper roller load distribution. This precision extends to the surface finish of all components, reducing friction and enabling the formation of stable lubricant films at high speeds.

What Are the Cost Benefits of Choosing Single Row Cylindrical Roller Bearings?

The economic advantages of single row cylindrical roller bearings extend beyond their initial purchase price. These bearings offer substantial long-term cost benefits through their durability, maintenance characteristics, and operational efficiency. Understanding these aspects helps organizations make informed decisions about their bearing selections.

The separable design of these bearings significantly reduces maintenance costs. During servicing, individual components can be inspected, cleaned, and replaced as needed, often extending the bearing's useful life well beyond that of non-separable alternatives. This feature proves particularly valuable in applications where complete bearing replacement would be costly or time-consuming.

Operating costs are also reduced through the bearings' excellent energy efficiency. The line contact between rollers and raceways, combined with optimized surface finishes, results in lower friction compared to many alternative bearing types. This reduced friction translates directly into lower energy consumption, particularly in high-speed applications where energy costs can be significant.

The standardization of single row cylindrical roller bearings across different manufacturers helps reduce inventory costs. Organizations can often maintain smaller spare parts inventories while still ensuring adequate coverage for their equipment. This standardization also facilitates easier sourcing and potentially better pricing through volume purchases.

Product Advantages of Luoyang Huigong Bearing Technology Co., Ltd.

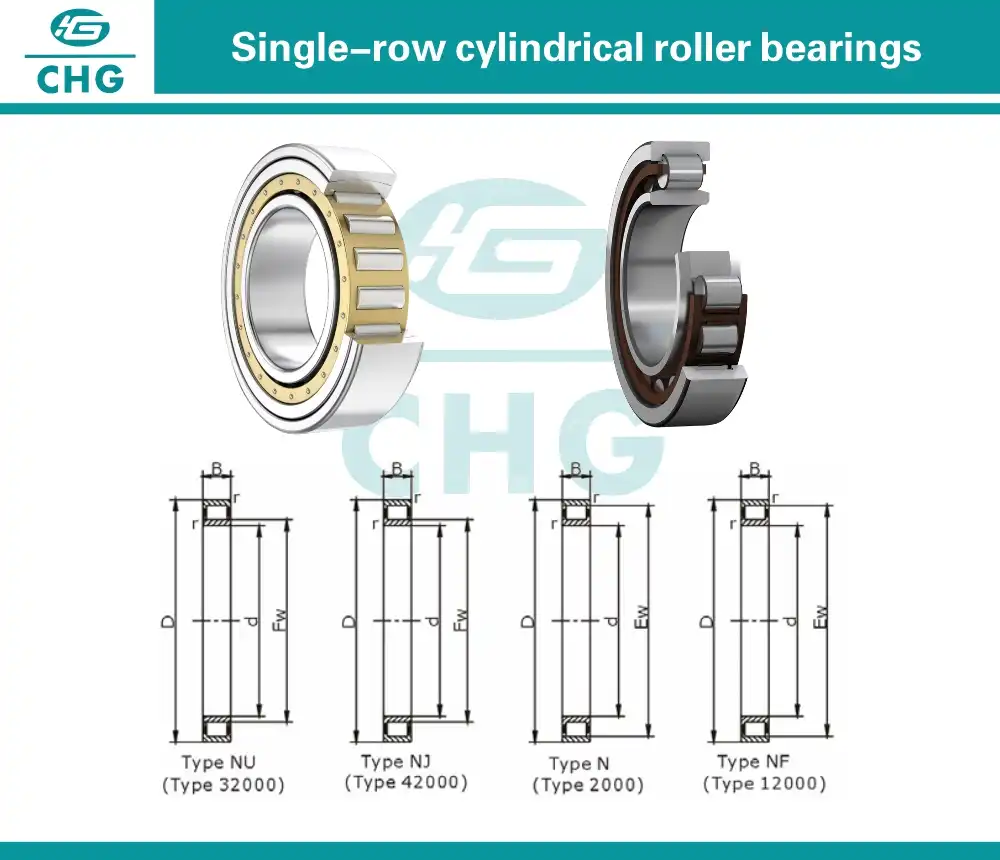

Luoyang Huigong Bearing Technology Co., Ltd. stands out in the market with its comprehensive range of single row cylindrical roller bearings. Their products feature exceptional design characteristics, including separable components consisting of inner ring, outer ring, rollers, and cage. The company offers various series types, including NU, NJ, N, and NF series, catering to diverse industrial needs.

The company's bearings excel in high-speed applications and offer superior radial load capacity compared to conventional ball bearings of similar size. Their products are engineered for easy assembly and disassembly, with roller guidance provided by two ribs of the bearing ring. The bearings maintain strict alignment requirements, typically less than 4' between inner and outer ring axes, with special profiling of rollers and raceway generatrix to optimize performance.

Manufacturing capabilities cover a wide size range with internal diameters from 120mm to 1320mm, utilizing high-quality materials such as GCr15, GCr15SiMn, and G20Cr2Ni4A. These specifications ensure reliable performance across various industrial applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. SKF Group. (2024). "Cylindrical roller bearings - Technical principles and design considerations."

2. NSK Ltd. (2023). "Roller Bearings Engineering Manual."

3. Timken Company. (2024). "Understanding Cylindrical Roller Bearing Technology."

4. Journal of Tribology. (2023). "Advanced Design Features in Modern Roller Bearings."

5. International Journal of Mechanical Engineering. (2023). "Cost Analysis of Industrial Bearing Applications."

6. Bearing News. (2024). "Trends in High-Speed Bearing Applications."

7. Manufacturing Technology Insights. (2023). "Innovations in Bearing Manufacturing."

8. Industrial Maintenance & Plant Operation. (2024). "Bearing Selection Guidelines."

9. Power Transmission Engineering. (2023). "Understanding Bearing Life and Performance."

10. Machine Design. (2024). "Cost-Effective Solutions in Industrial Bearings."