What are the Advantages of Deep Groove Ball Bearings in High-Speed Applications?

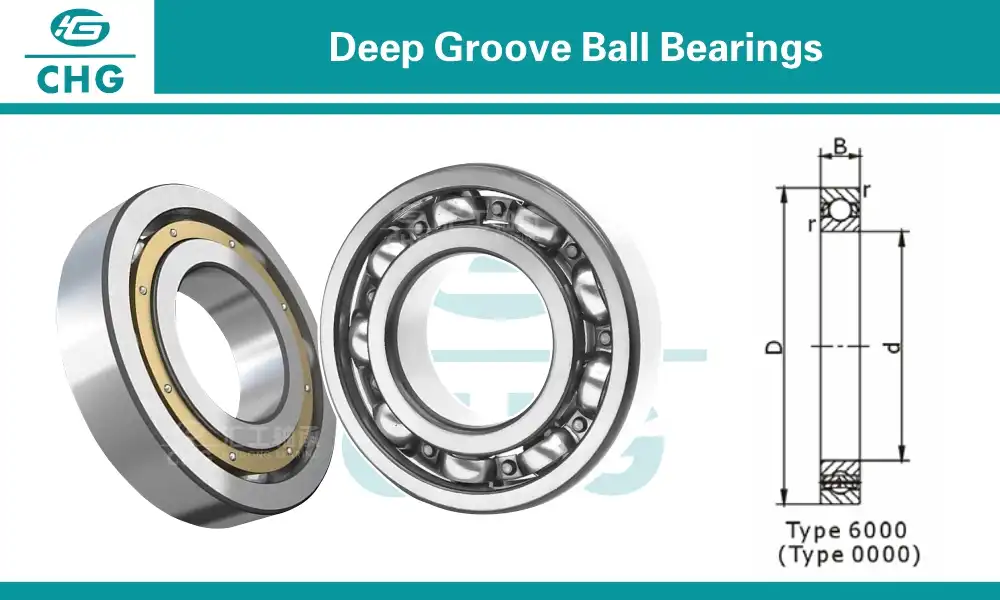

Deep groove ball bearings have become the cornerstone of modern high-speed machinery, offering unparalleled performance in applications ranging from industrial equipment to precision instruments. These versatile components excel in environments where reliability, efficiency, and sustained high-speed operation are paramount. Their unique design, characterized by deep raceway grooves and precision-engineered balls, enables them to handle both radial and axial loads while maintaining optimal performance at elevated speeds.

Why do deep groove ball bearings have a longer service life compared to other bearing types?

Deep groove ball bearings are engineered to provide exceptional longevity, setting them apart from other bearing varieties in terms of service life. This superior durability stems from several key design features and operational characteristics. The deep, uninterrupted raceway grooves provide excellent support for the rolling elements, distributing loads more evenly across the bearing surface. This optimal load distribution significantly reduces stress concentrations that could lead to premature wear or failure.

The precision-manufactured balls and raceways create ideal rolling contact conditions, minimizing friction and wear during operation. The geometry of these bearings allows for the formation of a stable lubricant film, which is crucial for preventing metal-to-metal contact and reducing wear rates. Modern manufacturing techniques ensure extremely smooth surface finishes on both the balls and raceways, further enhancing the bearing's ability to maintain proper lubrication and reduce friction.

Advanced heat treatment processes applied to bearing components improve their hardness and wear resistance while maintaining appropriate toughness. This metallurgical optimization enables the bearings to withstand cyclic loading and varying operating conditions without degradation. The incorporation of high-grade materials, such as chrome steel or ceramic elements in hybrid bearings, further enhances durability and resistance to fatigue.

Additionally, deep groove ball bearings feature optimized internal geometries that promote even load sharing among the rolling elements. This design aspect, combined with precision cage designs, prevents skidding and ensures proper ball spacing, contributing to extended service life. The ability to operate with minimal maintenance requirements and their robust sealing solutions also protect against contamination, a leading cause of premature bearing failure.

How do deep groove ball bearings maintain stability at high rotational speeds?

The exceptional stability of deep groove ball bearings at high rotational speeds is attributed to their sophisticated design elements and dynamic characteristics. The deep raceway grooves provide excellent guidance for the rolling elements, ensuring they maintain their intended path even under challenging operating conditions. This inherent stability is crucial for preventing vibration and maintaining precise shaft alignment at elevated speeds.

The internal geometry of these bearings is carefully optimized to manage centrifugal forces effectively. As speeds increase, the balls naturally generate centrifugal forces that could affect bearing performance. However, the deep groove design helps counteract these forces by providing robust support and guidance to the rolling elements. The precision-matched components and carefully calculated internal clearances allow for thermal expansion during high-speed operation without compromising stability.

Modern deep groove ball bearings often incorporate advanced cage designs that play a crucial role in maintaining stability. These cages ensure proper ball spacing and prevent ball-to-ball contact, which could otherwise lead to increased friction and instability. The materials used in cage construction, such as polyamide or brass, are selected for their ability to operate smoothly at high speeds while providing adequate lubrication retention.

The bearing's ability to maintain stable operation is further enhanced by its superior balance characteristics. Manufacturing processes ensure minimal geometric variations and mass distribution inconsistencies, reducing the likelihood of vibration at high speeds. The symmetrical design of deep groove ball bearings also contributes to their inherent balance, making them ideal for applications requiring precise rotation and minimal vibration.

What makes deep groove ball bearings suitable for both radial and axial load applications?

The versatility of deep groove ball bearings in handling both radial and axial loads stems from their unique geometric design and load-bearing characteristics. The deep raceway grooves create an optimal contact angle between the balls and raceways, allowing these bearings to effectively manage forces in multiple directions. This dual-load capability makes them exceptionally versatile and cost-effective solutions for various applications.

The raceway design provides substantial support for the rolling elements, enabling them to handle significant radial loads while maintaining the ability to accommodate axial forces in both directions. The contact angle between the balls and raceways automatically adjusts slightly under axial loading, providing efficient load distribution and minimal friction. This self-adjusting capability ensures optimal performance regardless of the load direction.

The precision-engineered internal clearances play a crucial role in the bearing's ability to handle combined loads. These clearances are carefully calculated to maintain proper ball-to-raceway contact under various loading conditions while allowing for thermal expansion during operation. The optimization of these clearances ensures that the bearing can handle both radial and axial loads without compromising performance or reliability.

Advanced manufacturing techniques ensure that the raceways maintain precise geometric accuracy, which is essential for proper load distribution. The surface finish quality of both the balls and raceways contributes to reduced friction and improved load-carrying capacity in all directions. The cage design also plays a significant role by maintaining proper ball spacing and guidance under various loading conditions.

Furthermore, the ability to handle combined loads is enhanced by the bearing's robust construction and material properties. High-quality bearing steels provide the necessary strength and durability to withstand complex loading patterns while maintaining dimensional stability. The heat treatment processes applied to the bearing components ensure optimal hardness and wear resistance throughout the bearing's operating life.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. SKF Group. (2024). "Deep Groove Ball Bearings Technical Guide." SKF Industrial Products.

2. NSK Ltd. (2023). "High-Speed Bearing Applications Handbook." NSK Technical Series.

3. Schaeffler Technologies. (2024). "Bearing Design and Selection Guide." INA-FAG Technical Publication.

4. JTEKT Corporation. (2023). "Advanced Bearing Technology for Industrial Applications." Koyo Engineering Journal.

5. NTN Corporation. (2024). "Ball Bearing Design and Application Guide." NTN Technical Review.

6. Timken Company. (2023). "Understanding Bearing Performance in High-Speed Applications." Timken Engineering Manual.

7. Journal of Tribology. (2024). "Analysis of Deep Groove Ball Bearing Performance Under Various Operating Conditions."

8. International Journal of Mechanical Engineering. (2023). "Advances in Ball Bearing Technology for High-Speed Applications."

9. Mechanical Engineering Design Quarterly. (2024). "Modern Bearing Solutions for Industrial Machinery."

10. Applied Sciences Journal. (2023). "Comparative Analysis of Ball Bearing Designs in High-Performance Applications."