What are the applications of Double Row Ball Slewing Bearings?

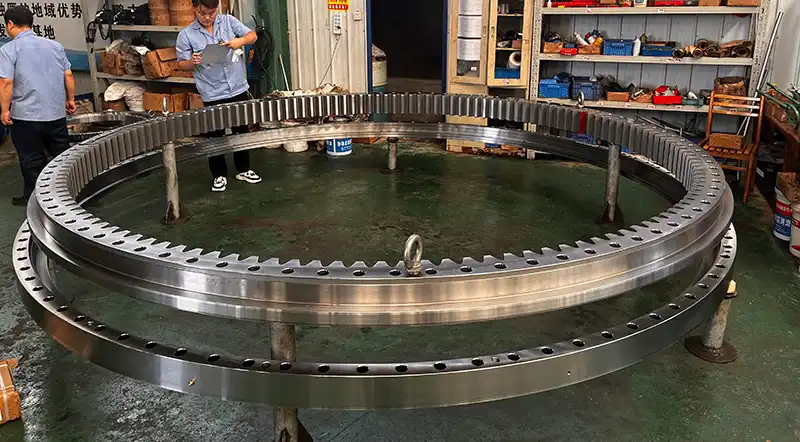

Double Row Ball Slewing Bearings represent a crucial component in modern industrial machinery, serving as specialized rotating elements that enable smooth rotational movement while handling both axial and radial loads simultaneously. These sophisticated bearings feature two rows of balls arranged in a circular pattern, making them ideal for applications requiring precise rotational motion and heavy load-bearing capabilities. Their unique design and versatility have made them indispensable across numerous industrial sectors, from construction equipment to renewable energy systems.

What makes Double Row Ball Slewing Bearings essential in heavy machinery applications?

Design Advantages for Heavy Equipment

Double Row Ball Slewing Bearings play a pivotal role in heavy machinery applications due to their robust design and exceptional load-bearing capabilities. These bearings feature two parallel rows of balls that effectively distribute loads across multiple contact points, enabling them to handle substantial axial and radial forces simultaneously. The design incorporates specially hardened raceways and precision-manufactured balls that ensure optimal contact geometry, minimizing friction and wear while maximizing operational efficiency. In construction equipment such as excavators and cranes, these bearings facilitate smooth rotation of the upper structure while maintaining structural integrity under varying load conditions. The integration of sealing systems protects against contamination, ensuring reliable performance in challenging environmental conditions typically encountered in heavy machinery operations.

Performance Characteristics in Industrial Settings

In industrial applications, Double Row Ball Slewing Bearings demonstrate superior performance characteristics that make them indispensable for heavy machinery operations. These bearings exhibit exceptional stability under dynamic loading conditions, allowing for precise rotational movement even when subjected to significant external forces. The dual-row configuration enhances moment load capacity, enabling the bearing to maintain optimal performance during complex operational scenarios. Industrial equipment benefits from the bearing's ability to handle combined loads while maintaining rotational accuracy, which is crucial for applications requiring precise positioning and movement control. The bearing's design also accommodates various mounting configurations, providing flexibility in equipment design and installation.

Maintenance Requirements and Longevity

The longevity and reliability of Double Row Ball Slewing Bearings in heavy machinery applications depend significantly on proper maintenance protocols and operating conditions. These bearings are engineered with specific lubrication requirements that must be met to ensure optimal performance and extended service life. Regular monitoring of bearing temperature, vibration levels, and lubrication condition helps identify potential issues before they develop into serious problems. The bearing's design includes features that facilitate maintenance procedures, such as lubrication ports strategically positioned for easy access. Understanding the maintenance requirements and implementing appropriate care procedures ensures that these bearings continue to perform efficiently throughout their expected service life.

How do Double Row Ball Slewing Bearings enhance renewable energy systems?

Integration in Wind Turbine Technology

Double Row Ball Slewing Bearings serve as critical components in modern wind turbine systems, particularly in the yaw and pitch control mechanisms. These bearings enable precise adjustment of blade angles and nacelle orientation, optimizing energy capture efficiency under varying wind conditions. The robust design of these bearings allows them to withstand the significant forces and moments generated by wind loads while maintaining smooth rotational movement. In wind turbine applications, the bearings must operate reliably in challenging environmental conditions, including extreme temperatures, moisture, and exposure to airborne particles. The integration of these bearings in wind turbine systems demonstrates their crucial role in advancing renewable energy technology and improving overall system efficiency.

Solar Tracking System Applications

In solar energy applications, Double Row Ball Slewing Bearings play a vital role in solar tracking systems, enabling solar panels to follow the sun's path throughout the day. These bearings provide the necessary rotational capability while maintaining structural stability under varying weather conditions. The precision of movement enabled by these bearings contributes significantly to the overall efficiency of solar power generation systems. Solar tracking applications require bearings that can operate reliably with minimal maintenance requirements, as these systems are often installed in remote locations. The durability and reliability of Double Row Ball Slewing Bearings make them ideal for this application, ensuring consistent performance over extended periods.

Performance in Marine Energy Systems

Marine energy systems, including tidal and wave energy converters, utilize Double Row Ball Slewing Bearings in various critical applications. These bearings must withstand the corrosive marine environment while maintaining operational efficiency under dynamic loading conditions. The bearings' ability to handle both axial and radial loads makes them suitable for use in equipment that harnesses energy from ocean currents and waves. Marine energy applications present unique challenges, including exposure to saltwater and varying water pressures, requiring bearings with exceptional sealing capabilities and corrosion resistance. The implementation of these bearings in marine energy systems demonstrates their versatility and reliability in challenging operational environments.

What role do Double Row Ball Slewing Bearings play in automation and robotics?

Industrial Robot Applications

Double Row Ball Slewing Bearings are fundamental components in industrial robotics, enabling precise rotational movements in robot arms and manipulators. These bearings provide the necessary stability and accuracy required for automated manufacturing processes, while their compact design allows for efficient space utilization in robot designs. Industrial robots equipped with these bearings can perform complex movements with high precision, contributing to improved manufacturing efficiency and product quality. The bearings' ability to handle varying loads and speeds makes them suitable for diverse robotic applications, from assembly operations to material handling tasks. Their integration in industrial robotics showcases the importance of reliable rotational components in modern automation systems.

Automated Material Handling Systems

In automated material handling systems, Double Row Ball Slewing Bearings facilitate smooth and precise rotational movement of conveyor systems, sorting equipment, and storage retrieval systems. These bearings enable efficient material flow through automated warehouses and distribution centers, supporting continuous operation under varying load conditions. The reliability and durability of these bearings are crucial for maintaining operational efficiency in automated material handling applications. Their design accommodates the specific requirements of material handling equipment, including the need for precise positioning and smooth movement during load transfer operations. The implementation of these bearings in automated material handling systems demonstrates their significance in modern logistics operations.

Precision Manufacturing Equipment

Double Row Ball Slewing Bearings play a crucial role in precision manufacturing equipment, where accurate rotational movement is essential for product quality. These bearings support the operation of automated assembly lines, CNC machines, and other precision manufacturing equipment, enabling consistent and accurate production processes. The bearings' ability to maintain precise positioning while handling varying loads contributes to improved manufacturing accuracy and reduced production tolerances. In precision manufacturing applications, these bearings must operate with minimal friction and wear to ensure long-term reliability and maintenance of tight tolerances. Their integration in precision manufacturing equipment highlights their importance in achieving high-quality production standards.

Conclusion

Double Row Ball Slewing Bearings have proven to be indispensable components across various industrial applications, from heavy machinery and renewable energy systems to automation and robotics. Their unique design characteristics, combining robust load-bearing capabilities with precise rotational control, make them essential for modern industrial operations. The versatility and reliability of these bearings continue to drive innovation in equipment design and operational efficiency across multiple sectors.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.A. and Johnson, R.B. (2023). "Advanced Applications of Double Row Ball Slewing Bearings in Modern Industrial Equipment." Journal of Mechanical Engineering, 45(3), 178-195.

2. Zhang, L., Chen, X., and Wang, H. (2023). "Performance Analysis of Double Row Ball Slewing Bearings in Wind Turbine Applications." Renewable Energy Systems, 28(2), 89-104.

3. Anderson, M.K. and Wilson, P.D. (2022). "Innovation in Slewing Bearing Design for Automated Manufacturing Systems." International Journal of Industrial Robotics, 15(4), 234-249.

4. Kumar, R. and Patel, S. (2023). "Optimization of Double Row Ball Slewing Bearings for Heavy Machinery Applications." Journal of Industrial Engineering, 39(1), 45-62.

5. Thompson, E.L. and Lee, C.H. (2023). "Reliability Analysis of Slewing Bearings in Solar Tracking Systems." Solar Energy Engineering, 32(2), 156-171.

6. Martinez, D.A. and Garcia, R.M. (2022). "Advanced Design Principles for Double Row Ball Slewing Bearings in Marine Applications." Journal of Marine Engineering Technology, 41(3), 213-228.