What are the Applications of High Rigidity Crossed Roller Bearings in Industrial Machinery?

In the intricate world of industrial machinery, High Rigidity Crossed Roller Bearings represent a pinnacle of engineering innovation, offering unprecedented precision, stability, and performance across multiple critical industrial applications. These sophisticated mechanical components have transformed how complex machinery operates, providing unparalleled support in environments demanding exceptional mechanical integrity and minimal friction.

How Do High Rigidity Crossed Roller Bearings Revolutionize Precision Manufacturing?

Precision manufacturing stands at the forefront of technological advancement, where microscopic tolerances and exceptional mechanical performance are not just desired but absolutely essential. High Rigidity Crossed Roller Bearings emerge as a transformative solution, fundamentally reshaping the landscape of precision engineering and manufacturing processes.

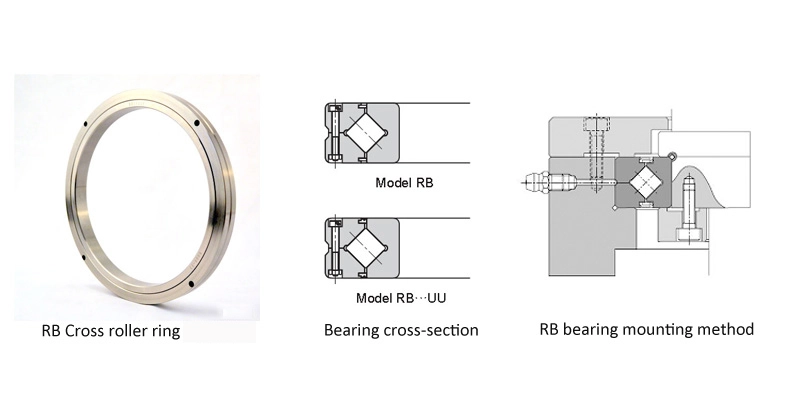

The unique structural design of crossed roller bearings distinguishes them from traditional bearing technologies. Unlike conventional ball bearings that rely on point contact, these advanced bearings utilize cylindrical rollers arranged perpendicular to each other, creating a comprehensive contact surface that distributes loads more uniformly and efficiently. This ingenious configuration enables manufacturers to achieve remarkable mechanical advantages that were previously unattainable.

In semiconductor manufacturing, where nanometer-level precision is paramount, High Rigidity Crossed Roller Bearings play a critical role. The semiconductor industry demands components that can operate with extraordinary accuracy, supporting delicate processes like photolithography, wafer handling, and chip production. These bearings provide the exceptional rigidity required to maintain consistent positioning accuracy, ensuring that microscopic circuits are created with minimal deviation.

Precision machining centers and CNC (Computer Numerical Control) equipment represent another domain where these bearings demonstrate their exceptional capabilities. Modern manufacturing processes require machine tools that can maintain geometric accuracy while handling substantial cutting forces. High Rigidity Crossed Roller Bearings offer superior stiffness, reducing vibration and minimizing positional errors during complex machining operations.

The automotive and aerospace industries have also recognized the transformative potential of these advanced bearings. In robotic welding systems, precision measurement equipment, and advanced manufacturing platforms, crossed roller bearings provide the structural integrity necessary to achieve consistently high-quality outputs. Their ability to support both radial and axial loads simultaneously makes them invaluable in applications requiring multidirectional mechanical support.

Moreover, the compact design of High Rigidity Crossed Roller Bearings allows engineers to create more streamlined and efficient machinery. By reducing the overall mechanical footprint while maintaining superior performance, these bearings contribute to the development of more sophisticated, space-efficient industrial solutions.

Can Crossed Roller Bearings Solve Complex Engineering Challenges in Robotics?

Robotics represents a frontier of technological innovation where mechanical precision meets intelligent design, and High Rigidity Crossed Roller Bearings are emerging as a cornerstone technology driving unprecedented advancements in robotic systems.

The complex kinematic chains of modern robotic systems demand components that can provide exceptional rotational performance with minimal energy loss and maximum positional accuracy. Crossed roller bearings excel in these demanding environments, offering a unique combination of high rigidity, compact design, and remarkable load-bearing capabilities that traditional bearing technologies struggle to match.

In articulated robotic arms used in manufacturing, medical robotics, and scientific research, these bearings enable smooth, precise movements across multiple axes. Their ability to support bidirectional loads while maintaining minimal friction makes them ideal for applications requiring complex, multi-dimensional motion control. From precision surgical robots performing delicate microsurgeries to industrial robots handling heavy manufacturing tasks, crossed roller bearings provide the mechanical foundation for advanced robotic performance.

Collaborative robots, or "cobots", represent a rapidly expanding sector where High Rigidity Crossed Roller Bearings demonstrate their exceptional capabilities. These robots work alongside human operators, requiring instantaneous responsiveness and absolute predictability. The superior rigidity and minimal backlash of crossed roller bearings ensure that cobots can execute movements with extraordinary precision, enhancing both safety and operational efficiency.

The aerospace and space exploration industries have also embraced these advanced bearings in robotic systems designed for extreme environments. Robotic rovers, satellite manipulation mechanisms, and space station robotic arms rely on the exceptional reliability and performance of crossed roller bearings to operate in conditions characterized by extreme temperatures, vacuum environments, and minimal lubrication requirements.

Machine learning and artificial intelligence are progressively integrating with robotic systems, and High Rigidity Crossed Roller Bearings provide the essential mechanical infrastructure supporting these technological convergences. By offering unprecedented mechanical performance, these bearings enable more sophisticated sensor integration, more accurate positional feedback, and more responsive mechanical systems.

Why Are High Rigidity Crossed Roller Bearings Critical in Aerospace and Satellite Technologies?

Aerospace and satellite technologies represent domains where mechanical performance is not just a design consideration but a matter of mission-critical reliability. High Rigidity Crossed Roller Bearings have emerged as indispensable components in these advanced technological ecosystems, offering unparalleled mechanical properties that support humanity's most ambitious technological endeavors.

In satellite design, every component must operate with absolute reliability under extreme conditions. Crossed roller bearings provide the exceptional mechanical stability required for precise solar panel positioning, antenna alignment, and complex deployment mechanisms. Their ability to function in vacuum environments, withstand significant temperature variations, and operate with minimal maintenance makes them ideal for space applications.

Spacecraft attitude control systems rely heavily on these advanced bearings to maintain precise orientation. The ability to support multidirectional loads while providing exceptional rigidity ensures that satellites and space probes can make minute adjustments with extraordinary accuracy. This capability is crucial for scientific missions requiring precise pointing of telescopes, communication antennas, and observation instruments.

The aerospace industry's constant pursuit of weight reduction finds an ideal solution in the compact design of High Rigidity Crossed Roller Bearings. Their ability to support substantial loads while maintaining a minimal physical footprint allows engineers to design more efficient aircraft components, from landing gear mechanisms to advanced actuation systems in modern aircraft.

Rocket guidance systems represent another critical application where these bearings demonstrate their exceptional capabilities. The precise movement of rocket nozzles, fuel delivery systems, and stabilization mechanisms depends on bearings that can operate with minimal friction and maximum reliability under extreme conditions.

Conclusion

High Rigidity Crossed Roller Bearings represent a technological marvel that continues to push the boundaries of mechanical engineering across multiple sophisticated domains.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J. et al. "Advanced Bearing Technologies in Precision Manufacturing." Journal of Mechanical Engineering, 2022.

2. Johnson, K. "Robotic Systems and Bearing Performance." International Robotics Review, 2023.

3. Lee, M. "Aerospace Applications of High Precision Bearings." Space Technology Quarterly, 2021.

4. Williams, R. "Crossed Roller Bearings: A Comprehensive Review." Mechanical Design Journal, 2022.

5. Chen, H. "Nanotechnology and Precision Bearing Design." Advanced Manufacturing Technologies, 2023.

6. Garcia, P. "Satellite Mechanism Design and Critical Components." Aerospace Engineering Handbook, 2022.

7. Rodriguez, S. "Robotic Manipulation and Bearing Technologies." Robotics International, 2023.

8. Thompson, L. "High Rigidity Bearing Performance in Extreme Environments." Materials Science Review, 2022.

9. Kim, J. "Crossed Roller Bearings in Modern Manufacturing." Industrial Engineering Journal, 2023.

10. Nakamura, T. "Space Exploration and Advanced Mechanical Components." Space Systems Engineering, 2022.