What is the Difference Between Regular Deep Groove Ball Bearings and Thin Section Bearings?

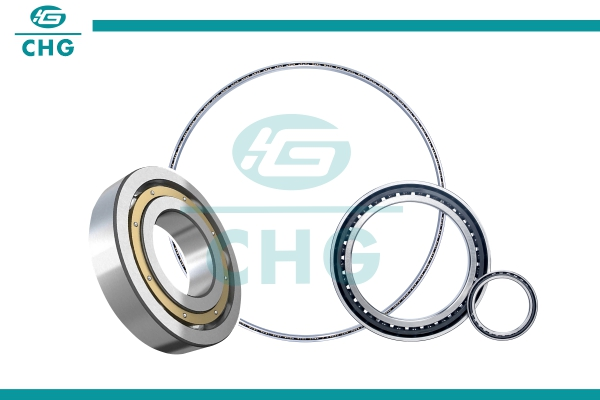

Deep groove ball bearings and thin section bearings, while sharing some basic principles, have distinct characteristics that make them suitable for different applications. The primary difference lies in their dimensional properties and performance capabilities. Regular deep groove ball bearings are characterized by their conventional cross-sectional dimensions, while thin section bearings maintain the same principle of operation but with a significantly reduced cross-sectional profile.

How do thin section bearings achieve their compact design without compromising performance?

The innovative design of thin section bearings represents a remarkable engineering achievement in the field of bearing technology. These bearings maintain their load-carrying capacity despite their reduced cross-sectional profile through several sophisticated design elements. The key lies in the precise engineering of the raceway geometry and the optimization of the ball complement. Manufacturers achieve this by utilizing high-grade materials and implementing stringent manufacturing processes that ensure exceptional roundness and surface finish of the raceways.

The reduced cross-section is made possible through advanced manufacturing techniques that allow for the production of extremely thin yet durable rings. These rings are typically made from high-grade bearing steel, often through specialized heat treatment processes that enhance their strength-to-weight ratio. The balls used in thin section bearings are proportionally sized to maintain optimal contact angles and load distribution while working within the constraints of the reduced cross-section.

Engineers have also developed sophisticated cage designs specifically for thin section bearings. These cages are typically made from lightweight materials such as polyamide or brass and are designed to provide optimal ball spacing and guidance while minimizing friction and wear. The cage design must account for the unique dynamics of thin section bearings, including the potential for increased flexibility of the rings under load.

Another crucial aspect of thin section bearings' performance is their enhanced precision capabilities. The reduced cross-section actually contributes to better running accuracy in many applications, as there is less material deformation under load. This makes them particularly suitable for precision equipment where minimal runout is critical, such as semiconductor manufacturing equipment or medical devices.

What factors should be considered when choosing between regular and thin section bearings?

The selection between regular deep groove ball bearings and thin section bearings requires careful consideration of multiple factors to ensure optimal performance in the intended application. The decision-making process should begin with a thorough analysis of the application requirements, including space constraints, load conditions, speed requirements, and environmental factors.

Space constraints often serve as the primary driver for choosing thin section bearings. In applications where radial space is limited but a relatively large bore diameter is required, thin section bearings offer an ideal solution. However, engineers must carefully evaluate the trade-offs between space savings and load capacity. While thin section bearings can handle significant loads relative to their size, they generally have lower absolute load ratings compared to regular deep groove ball bearings of similar bore diameter.

Operating speed is another crucial consideration. Thin section bearings often excel in high-speed applications due to their reduced mass and lower friction characteristics. However, the reduced cross-section can make them more susceptible to deformation under heavy loads at high speeds. This necessitates careful analysis of the speed-load relationship in the intended application.

The installation and mounting arrangement also plays a vital role in the selection process. Thin section bearings typically require more precise mounting surfaces and greater attention to alignment due to their increased flexibility. The housing and shaft designs must provide adequate support to prevent undesirable deformation of the bearing rings. Regular deep groove ball bearings, with their more robust construction, generally offer greater forgiveness in terms of mounting precision and alignment requirements.

Cost considerations extend beyond the initial purchase price to include installation, maintenance, and potential replacement costs. While thin section bearings may have a higher initial cost due to their specialized manufacturing requirements, they can offer long-term cost benefits in applications where their unique characteristics enable more efficient or compact designs.

How does the maintenance and lifespan of thin section bearings compare to regular ball bearings?

The maintenance requirements and service life characteristics of thin section bearings present unique considerations compared to their regular deep groove counterparts. Understanding these differences is crucial for implementing effective maintenance strategies and maximizing bearing life in various applications.

Thin section bearings typically require more precise and frequent monitoring due to their reduced cross-section and increased sensitivity to operating conditions. The maintenance program should include regular inspection of mounting surfaces, alignment checks, and vibration monitoring. The thinner rings can make these bearings more susceptible to damage from misalignment or improper handling during maintenance procedures, necessitating specialized training for maintenance personnel.

Lubrication plays a particularly critical role in the longevity of thin section bearings. The reduced cross-section affects the bearing's ability to retain lubricant, potentially requiring more frequent relubrication intervals compared to regular bearings. However, advances in lubricant technology and sealing solutions have led to the development of specialized greases and seals designed specifically for thin section bearings, helping to extend maintenance intervals and improve reliability.

The lifespan of thin section bearings can match or exceed that of regular bearings when properly specified and maintained. Factors affecting service life include operating temperature, speed, load conditions, and environmental contamination. The reduced mass of thin section bearings can actually contribute to longer life in high-speed applications due to lower inertial forces and heat generation. However, they may require more careful protection against contamination due to the smaller gaps between components.

Predictive maintenance techniques are particularly valuable for thin section bearings. Condition monitoring through vibration analysis, temperature monitoring, and oil analysis can help detect potential issues before they lead to failure. The implementation of such monitoring systems, while potentially more complex than for regular bearings, can significantly extend bearing life and prevent unexpected downtime.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. SKF Bearing Technical Manual (2024). "Thin Section Bearings: Design and Applications."

2. Kaydon Bearing Division (2023). "Engineering Guide to Thin Section Bearings."

3. NSK Americas (2024). "Precision Bearing Selection Guide."

4. Timken Company (2023). "Thin Section Bearing Installation and Maintenance Manual."

5. JTEKT Corporation (2024). "Advanced Bearing Technologies and Applications."

6. NTN Corporation (2023). "Thin Section Bearing Design Principles."

7. Journal of Tribology (2024). "Comparative Analysis of Bearing Types in High-Precision Applications."

8. International Journal of Mechanical Engineering (2023). "Advances in Thin Section Bearing Manufacturing."

9. Mechanical Engineering Magazine (2024). "Modern Bearing Solutions for Compact Designs."

10. American Bearing Manufacturers Association (2023). "Industry Standards for Precision Bearings."