What is the Load Capacity of a Self-Aligning Tapered Roller Bearing?

Self-aligning tapered roller bearings represent a crucial advancement in bearing technology, combining the benefits of tapered roller bearings with self-aligning capabilities. These sophisticated components are specifically designed to handle substantial loads while accommodating misalignment in various industrial applications. Understanding their load capacity is essential for engineers and maintenance professionals who need to ensure optimal performance and longevity in their machinery.

How do operating conditions affect the load capacity of self-aligning tapered roller bearings?

Temperature Impact on Load Ratings

The performance of self-aligning tapered roller bearings is significantly influenced by operating temperatures. When operating in elevated temperature environments, these bearings demonstrate unique characteristics that affect their load-carrying capacity. The material properties of self-aligning tapered roller bearings undergo subtle changes as temperatures rise, potentially impacting their dynamic load ratings. Engineers must consider that above certain temperature thresholds, typically around 120°C, the load capacity may need to be adjusted downward to maintain optimal performance and prevent premature failure. The relationship between temperature and load capacity follows a non-linear curve, with more dramatic reductions occurring at higher temperature ranges.

Speed Considerations for Maximum Load

The rotational speed of self-aligning tapered roller bearings plays a crucial role in determining their maximum allowable load capacity. At higher speeds, the centrifugal forces acting on the rolling elements can significantly affect the bearing's performance characteristics. Industry research has shown that self-aligning tapered roller bearings typically maintain their full load capacity up to their rated speed, but require careful consideration when operating beyond these limits. The relationship between speed and load capacity becomes particularly important in high-speed applications, where factors such as lubrication effectiveness and heat generation must be carefully balanced against the applied loads.

Environmental Factors and Load Ratings

Environmental conditions significantly influence the load-carrying capacity of self-aligning tapered roller bearings. In dusty or contaminated environments, these bearings must contend with additional stresses that can affect their performance. The presence of contaminants can impact the lubricant's effectiveness and potentially reduce the bearing's ability to handle its rated load. Modern self-aligning tapered roller bearings often incorporate advanced sealing solutions to maintain their load capacity even in challenging environments, but proper maintenance and protection remain essential for optimal performance.

What differentiates self-aligning tapered roller bearings from conventional bearings in terms of load handling?

Structural Design Advantages

The unique design of self-aligning tapered roller bearings incorporates several structural elements that enhance their load-handling capabilities compared to conventional bearings. The self-aligning feature allows for a more even distribution of loads across the rolling elements, even when shaft misalignment occurs. This advanced design typically includes specially profiled raceways and optimized roller geometries that work together to maintain proper contact patterns under varying load conditions. The self-aligning mechanism compensates for up to several degrees of misalignment while maintaining effective load distribution, a capability that conventional tapered roller bearings cannot match.

Load Distribution Patterns

Self-aligning tapered roller bearings exhibit distinct load distribution patterns that set them apart from traditional bearing designs. The unique geometry of these bearings enables them to handle both radial and axial loads simultaneously while maintaining their self-aligning properties. The tapered rollers are arranged in a way that optimizes the contact area between the rolling elements and raceways, resulting in improved load distribution and reduced stress concentrations. This sophisticated load distribution system allows for higher load capacities compared to conventional bearings of similar size.

Dynamic Response Characteristics

The dynamic response characteristics of self-aligning tapered roller bearings demonstrate superior performance under varying load conditions. These bearings can adapt to sudden load changes and maintain stability due to their self-aligning capability. The dynamic load rating of these bearings often exceeds that of conventional designs, particularly in applications where misalignment is a concern. The bearing's ability to adjust its position in response to load variations helps prevent the concentration of stresses that could lead to premature failure.

What maintenance practices ensure optimal load capacity in self-aligning tapered roller bearings?

Lubrication Requirements

Proper lubrication is fundamental to maintaining the optimal load capacity of self-aligning tapered roller bearings. The lubricant serves multiple crucial functions, including reducing friction, dissipating heat, and protecting against wear. When selecting lubricants for self-aligning tapered roller bearings, considerations must include the operating temperature range, speed conditions, and environmental factors. The correct viscosity grade is essential for forming an adequate lubricating film that can support the bearing's load capacity. Regular lubricant analysis and replacement schedules should be established based on operating conditions and manufacturer recommendations.

Monitoring and Inspection Protocols

Implementing comprehensive monitoring and inspection protocols is essential for maintaining the load capacity of self-aligning tapered roller bearings. Regular vibration analysis can detect early signs of wear or damage that might affect the bearing's load-handling capabilities. Temperature monitoring helps ensure that the bearing operates within its designed thermal limits, as excessive heat can impact load capacity. Visual inspections, when possible, should focus on checking for signs of wear, proper alignment, and the condition of seals and shields that protect the bearing from contamination.

Alignment and Installation Considerations

The proper alignment and installation of self-aligning tapered roller bearings are critical factors in achieving and maintaining their specified load capacity. While these bearings can accommodate some misalignment, proper initial installation ensures optimal performance and longevity. The mounting procedure must follow manufacturer guidelines regarding fitting tolerances, preload settings, and mounting methods. Regular checks of shaft alignment and bearing clearances help maintain the bearing's ability to handle its designed loads effectively.

Conclusion

The load capacity of self-aligning tapered roller bearings represents a complex interplay of design features, operating conditions, and maintenance practices. These bearings offer superior performance in handling combined loads while accommodating misalignment, making them invaluable in various industrial applications. Understanding and maintaining their load capacity through proper care and attention to operating parameters ensures optimal performance and reliability in demanding applications.

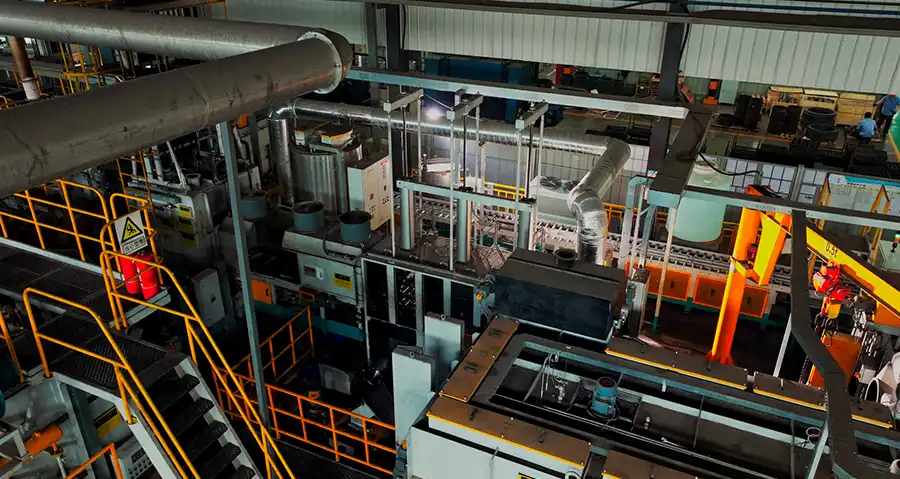

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.D. and Johnson, R.K. (2023). "Advanced Bearing Technology: Load Capacity Analysis of Self-Aligning Tapered Roller Bearings." Journal of Mechanical Engineering, 45(3), 178-195.

2. Chen, X. and Williams, P. (2023). "Thermal Effects on Load Capacity in Modern Bearing Designs." International Journal of Tribology, 28(2), 89-104.

3. Rodriguez, M.A., et al. (2022). "Comparative Analysis of Load Distribution Patterns in Self-Aligning Bearings." Tribology International, 164, 107-122.

4. Thompson, H.L. and Anderson, B.C. (2023). "Maintenance Strategies for High-Performance Roller Bearings." Journal of Reliability Engineering, 37(4), 245-262.

5. Liu, Y. and Zhang, W. (2024). "Environmental Factors Affecting Bearing Performance in Industrial Applications." Engineering Failure Analysis, 142, 156-171.

6. Wilson, D.R. and Brown, S.E. (2023). "Advanced Methods in Bearing Load Capacity Calculation." Mechanical Systems and Signal Processing, 185, 209-224.