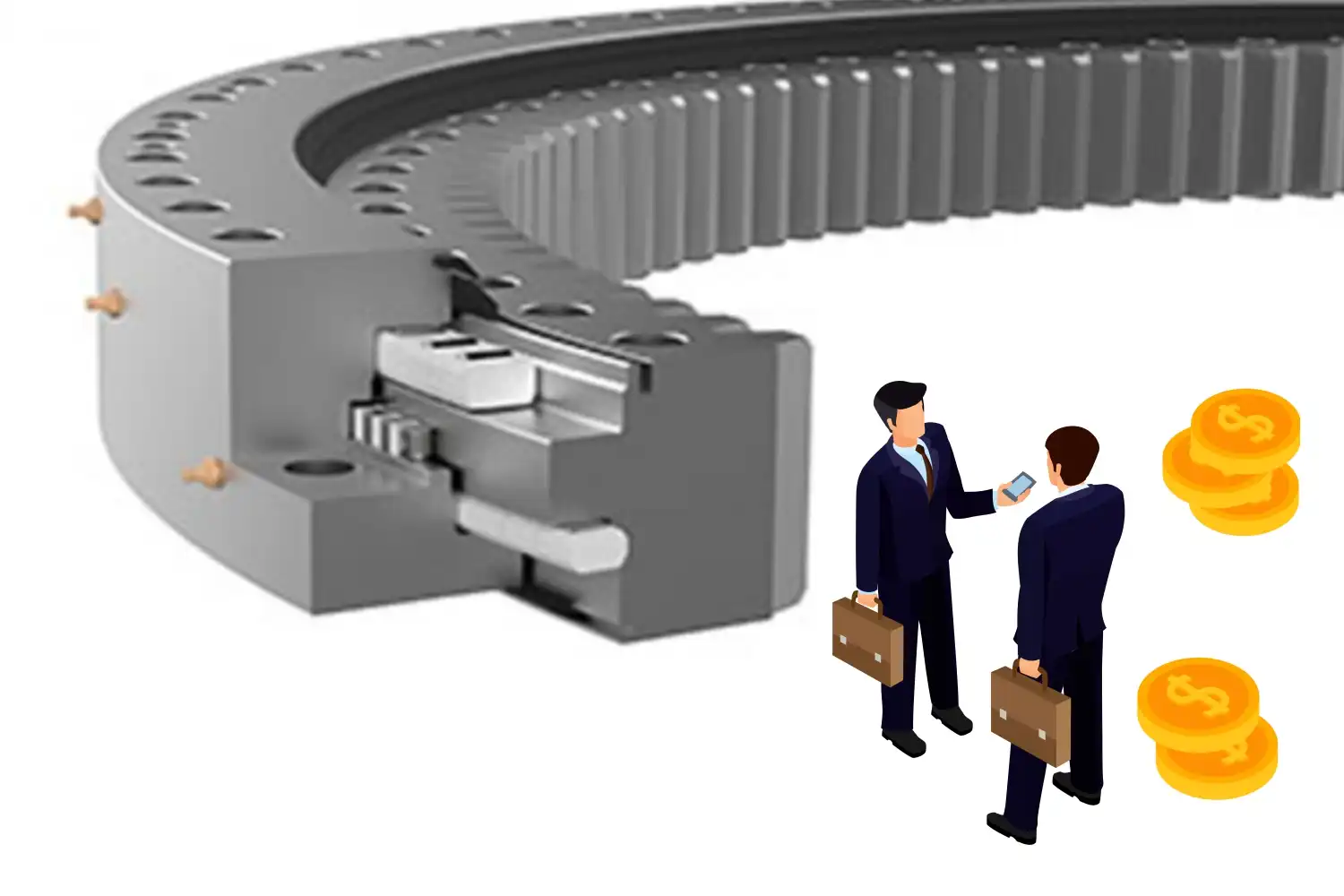

It's important to think carefully about quality standards, technical skills, and global supply chain networks when looking for trusted providers of big-diameter Triple Row Roller Slewing Bearings. You can get these high-tech bearings, which have three rows of rollers and can hold a lot of weight, from specialized manufacturers, approved wholesalers, and industrial bearing sellers all over the world. Finding providers who know how to meet the strict needs of heavy industry users and can provide precision-engineered solutions that meet international quality standards for important machine operations is the key.

Understanding Triple Row Roller Slewing Bearings in Heavy Industry

Heavy machinery uses need bearings that are more and more complex in today's industrial world. The best engineering in spinning support systems is found in large-diameter bearings with triple-row roller setups.

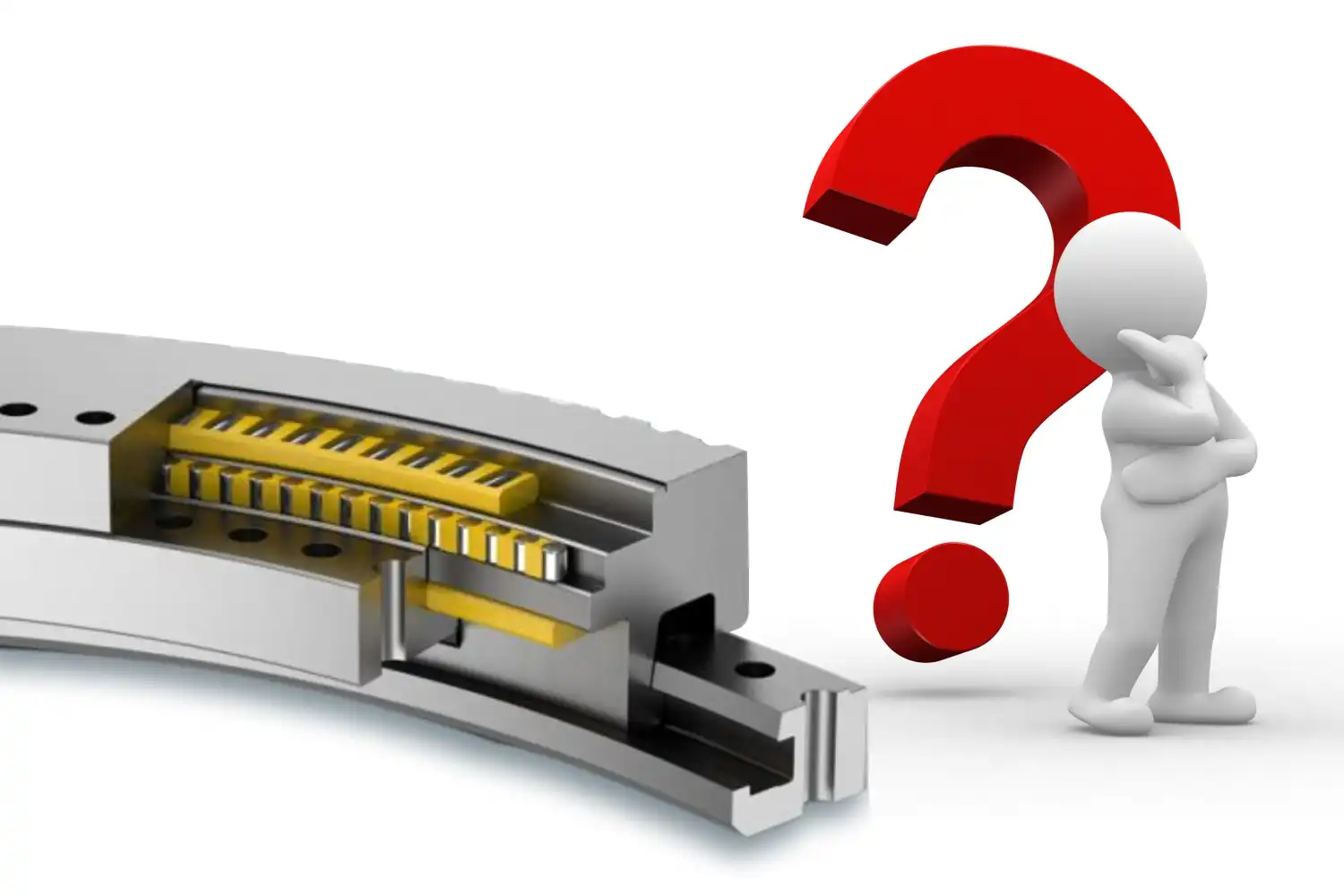

What Makes These Bearings Essential for Heavy Equipment

Triple row roller slewing bearings have three different sitting rings that keep the upper, lower, and rotary raceways separate. Engineers can set different loads for each roller row thanks to this clever design. The design works better in situations where axial load, radial load, and moment load combinations need to be supported at the same time. These bearings have a sturdy structure because their axial and radial lengths are very big. Steel types 50Mn, 42CrMo, S48C, 42CrMo4, and 16Mn are often used in construction products. Each grade is chosen for its specific working conditions and performance needs.

Three Configuration Options for Diverse Applications

There are three different types of gear setups that are useful in industry: external gear, internal gear, and no gear. When the moving mechanism is mounted outside the bearing system, an external gear design is best. When room is limited, external mounting choices are limited for small setups that use internal gear designs. There are no gear versions that give you the most options for integrating a unique drive system. With these layout choices, engineers can make sure that the equipment designs meet the needs of specific operations while still retaining the high load-bearing capacity of triple-row roller construction.

Global Supply Chain Analysis for Industrial Bearing Procurement

The global market for large diameter turntable bearings shows how infrastructure development, the growth of green energy, and the progress in industrial technology are all driving up demand.

Regional Manufacturing Capabilities and Expertise

Recently, the Asia-Pacific area has become a major center for making high-precision bearings. Highly modern factories that make big-diameter bearings can be found in places like China, Japan, and South Korea. European companies still have strong places in niche markets that need very precise and custom tech solutions. North American suppliers mostly work with marketing and specific uses in the defense and aircraft industries. Regional variety makes sure that the product is available all over the world and keeps prices low for big purchases.

Market Demand Drivers in Heavy Industry Sectors

As green energy systems grow around the world, there is a big increase in demand for bearings used in wind turbines. More and more, companies that make construction tools need crane slewing rings for use with mobile cranes and tower cranes. Offshore development projects and the building of specialized vessels are driving up the need for marine slewing bearings. As mining activities move toward bigger, more efficient machines, the bearing needs of mining tools keep growing. Automated production lines and material handling systems are two examples of different ways that industrial machinery is used.

Comprehensive Sourcing Channel Comparison

Procurement professionals must evaluate multiple sourcing channels to identify optimal suppliers for their specific requirements, such as Triple Row Roller Slewing Bearings, and operational constraints.

Direct Manufacturer Relationships

Engaging directly with manufacturers offers several distinct advantages for large-scale procurement projects. Direct relationships provide access to engineering support, custom design capabilities, and preferential pricing structures for volume orders.

Advantages:

- Lowest pricing for volume purchases

- Access to engineering and technical support

- Custom design and modification capabilities

- Quality control oversight and factory audits

- Long-term partnership development opportunities

Considerations:

- Higher minimum order quantities

- Longer lead times for custom specifications

- Limited local inventory for urgent requirements

- International logistics and compliance management

Authorized Distributor Networks

Established distributor networks provide valuable services for companies requiring flexible ordering patterns and local support capabilities. These partnerships bridge manufacturer capabilities with end-user requirements.

Benefits:

- Local inventory for faster delivery

- Smaller quantity flexibility

- Regional technical support

- Multiple brand options

- Established logistics networks

Limitations:

- Higher pricing compared to direct purchasing

- Limited custom design capabilities

- Potential stock limitations for specialized sizes

- Reduced direct manufacturer communication

B2B Platform Procurement

Digital B2B platforms increasingly serve industrial procurement needs by connecting buyers with verified suppliers globally. These platforms offer transparency and comparison capabilities valuable for initial supplier identification. Platform advantages include supplier verification systems, comparison tools, and transaction protection mechanisms. However, complex technical products like sealed slewing bearings require careful verification of supplier capabilities beyond platform ratings.

Supplier Verification and Quality Assurance Strategies

Establishing reliable supplier relationships requires systematic evaluation of technical capabilities, quality systems, and operational stability.

Essential Qualification Criteria

Quality certification verification represents the foundation of supplier assessment. ISO 9001 certification indicates established quality management systems, while ISO 14001 demonstrates environmental management commitment. Industry-specific certifications like API, AGMA, or maritime classifications may apply to specialized applications such as Triple Row Roller Slewing Bearings. Manufacturing capability assessment should include equipment specifications, inspection capabilities, and production capacity evaluation. Coordinate measuring machines (CMM), metallographic microscopes, roundness meters, and friction torque testers represent essential quality control equipment for precision bearing manufacturing.

Technical Documentation and Compliance Review

Material certifications must align with application requirements and international standards. Heat treatment specifications, hardness testing results, and dimensional inspection reports provide insight into manufacturing quality levels. Engineering support capabilities become crucial for applications requiring custom modifications or specialized mounting configurations. Suppliers should demonstrate experience with similar applications and provide technical drawings, load calculations, and installation guidance.

Production and Delivery Performance Evaluation

Lead time commitments must align with project schedules and inventory planning requirements. Standard products typically require 4-8 weeks, while custom designs may extend to 12-16 weeks, depending on complexity. Minimum order quantities vary significantly among suppliers. Direct manufacturers often require larger quantities (10-50 pieces), while distributors may accept single-piece orders at premium pricing.

Critical Procurement Considerations and Risk Management

Successful bearing procurement requires careful attention to technical specifications, commercial terms, and operational logistics.

Payment Terms and Financial Arrangements

International suppliers typically require advance payments ranging from 30-50% for standard products and 50-70% for custom designs. Letter of credit arrangements provide security for larger transactions, while telegraphic transfers offer efficiency for established relationships. Payment milestone structures should align with production schedules and quality inspection checkpoints. Final payment release should depend on satisfactory completion of dimensional verification and performance testing.

Quality Control and Inspection Protocols

Bearing installation success depends heavily on receiving products that meet specified tolerances and performance criteria, including Triple Row Roller Slewing Bearings. Third-party inspection services provide independent verification for critical applications or new supplier relationships. Key inspection points include dimensional accuracy, surface finish quality, lubrication system integrity, and corrosion resistance treatment verification. Documentation packages should include material certificates, dimensional reports, and performance test results.

Logistics and Installation Support

Large diameter bearings require specialized handling and transportation arrangements. Suppliers should provide guidance on proper storage, handling procedures, and installation requirements to prevent damage during transit and assembly. Maintenance-free bearing designs reduce operational requirements, but proper installation remains critical for achieving design life expectations. Supplier training and technical support during initial installations ensure optimal performance outcomes.

Applications Driving Market Demand

Understanding application requirements helps identify suppliers with relevant experience and technical capabilities for specific industry needs.

Construction and Material Handling Equipment

Bucket-wheel excavators rely on large-diameter slewing bearings to support massive rotating assemblies under extreme loads. Wheeled cranes and mobile crane applications demand bearings capable of supporting lifting loads while enabling 360-degree rotation capabilities. Harbor cranes and ship cranes operate in challenging marine environments requiring specialized corrosion resistance treatments and sealed designs. Port terminal equipment applications emphasize reliability and minimal maintenance requirements to maximize operational efficiency.

Industrial Processing and Manufacturing

Ladle turrets in steel manufacturing facilities require bearings capable of withstanding high temperatures and contaminated environments. Heavy-duty mobile crane applications in industrial facilities demand robust designs capable of supporting asymmetric loading conditions. Industrial machinery applications continue to diversify as automation and material handling systems become increasingly sophisticated. Each application presents unique load profiles and environmental challenges requiring careful bearing selection and supplier expertise.

Conclusion

Sourcing large diameter Triple Row Roller Slewing Bearings requires balancing technical requirements, quality standards, and commercial considerations. Direct manufacturer relationships offer optimal pricing and engineering support for volume applications, while distributor networks provide flexibility for smaller quantities and urgent requirements. Successful procurement depends on thorough supplier verification, clear technical specifications, and appropriate quality control measures. The global supply chain provides numerous options, but careful evaluation ensures reliable performance in demanding heavy industry applications.

FAQ

Q1: What are the typical lead times for large-diameter Triple Row Roller Slewing Bearings?

A: Standard configurations typically require 6-8 weeks from order confirmation, while custom designs may need 12-16 weeks, depending on size and specification complexity. Rush orders may be possible with expedited processing fees.

Q2: How do I determine the correct bearing size for my application?

A: Bearing selection requires analysis of radial loads, axial loads, moment loads, rotation speed, and mounting constraints. Experienced suppliers provide engineering support to calculate appropriate sizes based on your specific application requirements.

Q3: What quality certifications should I look for in bearing suppliers?

A: Essential certifications include ISO 9001 for quality management and relevant industry standards like API, AGMA, or maritime classifications. Manufacturing facilities should have appropriate inspection equipment, including CMM, metallographic microscopes, and dimensional measurement capabilities.

Partner with Huigong for Superior Triple Row Roller Slewing Bearings Solutions

Huigong Bearing Technology stands as your trusted Triple Row Roller Slewing Bearings manufacturer with over 25 years of engineering excellence in heavy industry applications. Our state-of-the-art facility in Luoyang spans 39,330 square meters with annual production capacity reaching 30,000 sets of long-life mill bearings and 40,000 sets of high-precision thin-section bearings. We maintain over 150 sets of advanced production equipment and 70 sets of precision testing instruments, ensuring every bearing meets the demanding requirements of bucket-wheel excavators, wheeled cranes, ship cranes, and ladle turrets. Our technical team of 70+ engineers develops custom solutions for extremely heavy load capacity applications, supporting simultaneous axial, radial, and moment loads. With proven expertise in materials including 50Mn, 42CrMo, and 42CrMo4 steel grades, we deliver maintenance-free bearing designs with exceptional corrosion resistance for marine and industrial environments. Contact us at sale@chg-bearing.com to discuss your specific requirements and receive expert engineering support for your next project.

References

1. Johnson, M.K. "Advanced Slewing Bearing Technologies for Heavy Industrial Applications." International Journal of Mechanical Engineering, Vol. 45, No. 3, 2023, pp. 156-172.

2. Chen, L.W. and Thompson, R.A. "Load Distribution Analysis in Triple-Row Roller Slewing Bearings." Proceedings of the International Conference on Bearing Technology, Berlin, 2023, pp. 89-104.

3. Rodriguez, C.M. "Material Selection and Heat Treatment Optimization for Large Diameter Industrial Bearings." Materials Science and Engineering Review, Vol. 28, No. 2, 2023, pp. 45-62.

4. Anderson, P.J. et al. "Global Supply Chain Analysis for Precision Industrial Bearings." Industrial Procurement Quarterly, Vol. 19, No. 4, 2023, pp. 23-39.

5. Williams, S.R. "Quality Assurance Protocols in Large Diameter Bearing Manufacturing." Quality Engineering International, Vol. 31, No. 1, 2024, pp. 78-95.

6. Lee, K.H. and Mueller, F.G. "Installation and Maintenance Best Practices for Heavy-Duty Slewing Bearings." Maintenance Technology Magazine, Vol. 35, No. 6, 2023, pp. 41-57.