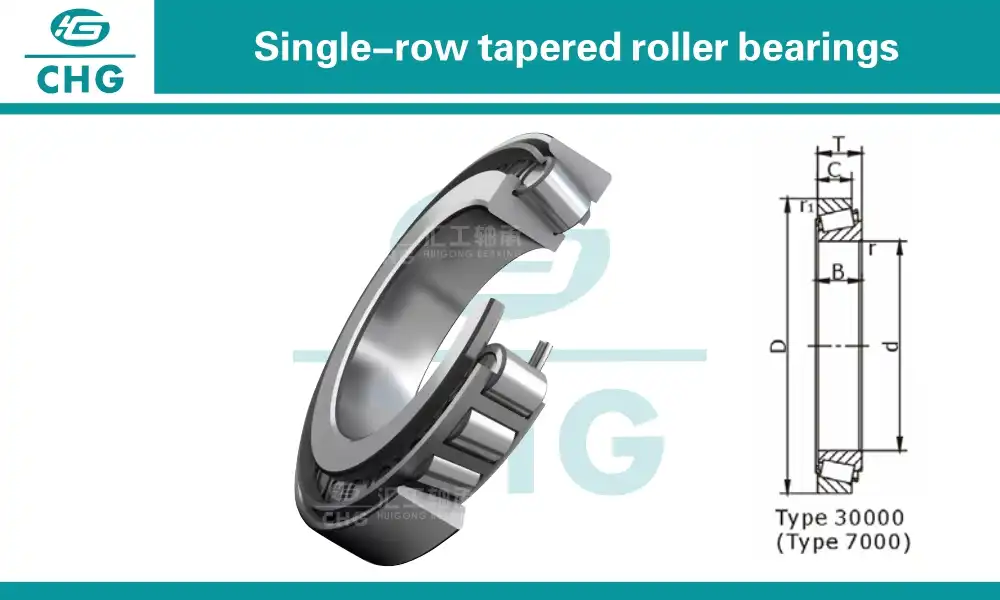

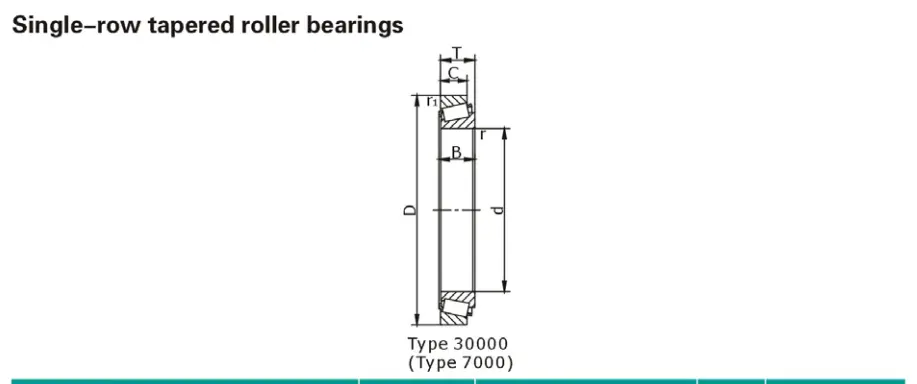

Cup Tapered Roller Bearing

2. Application: Tapered roller bearings are widely used in rear axle hubs of automotives, large machine tool spindles, large power reducer, roller wheels of feedways.

3. Matched Type: face to face, back to back, in tandet

4. Size range: Inter diameter:150-950mm

5. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

What is a Cup Tapered Roller Bearing?

A cup tapered roller bearing is an advanced bearing designed to support both radial and axial loads in industrial machinery. Unlike traditional bearings, the tapered roller design allows for a more effective distribution of forces, enhancing the stability and durability of rotating equipment. This type of bearing features tapered rollers arranged in a conical shape, which enables it to handle complex load conditions with greater precision.

Why Choose CHG Bearing?

CHG Bearing stands out as a leading manufacturer and supplier of cup tapered roller bearing. Here’s why you should consider us for your bearing needs:

Customization and Solutions: We provide tailored solutions for different working conditions. Whether you need bearings for high-temperature environments or specific load requirements, we have the expertise to deliver precisely what you need.

Experience and Expertise: With over 30 years of experience in the industry, CHG Bearing has built strong relationships with major companies, showcasing our commitment to quality and reliability.

Innovative Technology: Our company holds more than 50 invention patents, reflecting our dedication to innovation. We adhere to rigorous standards, with certifications including ISO9001 for quality management and ISO14001 for environmental management.

For more information or to request a quote, contact us at sale@chg-bearing.com.

Technical Specifications

| Specification | Details |

|---|---|

| Type | Cup Tapered Roller Bearing |

| Material | High-Grade Steel, Chrome Steel |

| Load Capacity | High Radial and Axial Load Capacity |

| Temperature Range | Up to 150°C (302°F) |

| Certification | ISO9001, ISO14001, GJB9001C-2017 |

| Custom Options | Sizes, Materials, Lubrication Methods |

Cup Tapered Roller Bearing Benefits

Enhanced Load Capacity: Designed to handle both radial and axial loads, our products ensure that your machinery operates smoothly under heavy conditions.

Improved Durability: The tapered design reduces stress on the rolling elements, leading to longer service life and reduced maintenance.

High Precision: Manufactured with strict tolerances, these bearings provide accurate and reliable performance, ensuring consistent operation of your equipment.

Versatility: Suitable for a wide range of industrial applications, from metallurgical and mining equipment to production machinery.

Applications

Cup tapered roller bearings are ideal for use in:

- Metallurgical Equipment: Blast furnaces, rolling mills, steelmaking equipment.

- Mining Machinery: Jaw crushers, impact crushers, vibrating screens, feeders.

- Heavy-Duty Equipment: Any machinery requiring robust and reliable bearing support.

Installation Guide

Preparation: Ensure the installation area is clean and free of debris. Verify that the bearing and related components are in good condition.

Lubrication: Apply the appropriate lubrication as recommended for your specific bearing type and operating conditions.

Alignment: Carefully align the bearing with the shaft and housing to prevent misalignment issues.

Mounting: Use proper tools and techniques to press the bearing into place, ensuring a snug fit without causing damage.

Inspection: After installation, check for smooth operation and absence of abnormal noises.

Maintenance and Care

To ensure the longevity and performance of your cup tapered roller bearing:

Regular Inspection: Monitor the bearing for signs of wear, noise, or vibration.

Lubrication: Keep the bearing properly lubricated according to the manufacturer’s recommendations to reduce friction and wear.

Cleaning: Periodically clean the area around the bearing to prevent the accumulation of dirt and debris.

Adjustments: Make necessary adjustments to maintain proper alignment and operational efficiency.

FAQ

Q: What are the benefits of using Cup Tapered Roller Bearings over other types?

A: They offer superior load capacity, enhanced durability, and high precision, making them suitable for demanding industrial applications.

Q: Can I customize?

A: Yes, we offer customization options including size, material, and lubrication methods to meet your specific needs.

Q: How do I know if my bearing needs maintenance?

A: Regular inspections and monitoring for abnormal noises or vibrations can help determine if maintenance is needed.

Customer Reviews

"CHG Bearing’s products have significantly improved the reliability of our equipment. Their customization options and quick response time make them a trusted supplier in our industry." — John D., Purchasing Manager

"With their extensive experience and high-quality products, CHG Bearing is our go-to source for bearings. Their products have exceeded our expectations in terms of performance and durability." — Emily R., Technical Engineer

Contact Us

For inquiries, quotes, or more information about our products, please reach out to us at sale@chg-bearing.com. Our team is here to provide you with the best solutions for your industrial bearing needs.

By incorporating these key elements and focusing on the needs of your target audience, this product page is designed to engage potential customers and boost your site’s authority in the industry.

YOU MAY LIKE

VIEW MOREFour Row Cylindrical Roller Bearing

VIEW MOREFour Row Cylindrical Roller Bearing VIEW MORELarge Cylindrical Roller Bearing

VIEW MORELarge Cylindrical Roller Bearing VIEW MORESpherical Roller Bearing

VIEW MORESpherical Roller Bearing VIEW MORESingle Row Tapered Roller Bearing

VIEW MORESingle Row Tapered Roller Bearing VIEW MOREThrust Bearing

VIEW MOREThrust Bearing VIEW MOREDouble Row Tapered Roller Bearing

VIEW MOREDouble Row Tapered Roller Bearing VIEW MORECylindrical Thrust Roller Bearings

VIEW MORECylindrical Thrust Roller Bearings VIEW MOREAxial Cylindrical Roller Bearing

VIEW MOREAxial Cylindrical Roller Bearing