Double Row Tapered Roller Bearing

2. Application:rolling mills, gearboxes, hoisting equipment, mining machines, tunnelling machines.

3. Advantage: Double row taper roller bearings have a small number of parts and high stiffness, and are easy to be mounted and dismounted, therefore, they are usually used in the applications with changes loads, such as reducers and coiling machines. The radial and axial clearance can be adjusted by changing the width of spacer between two inner rings.

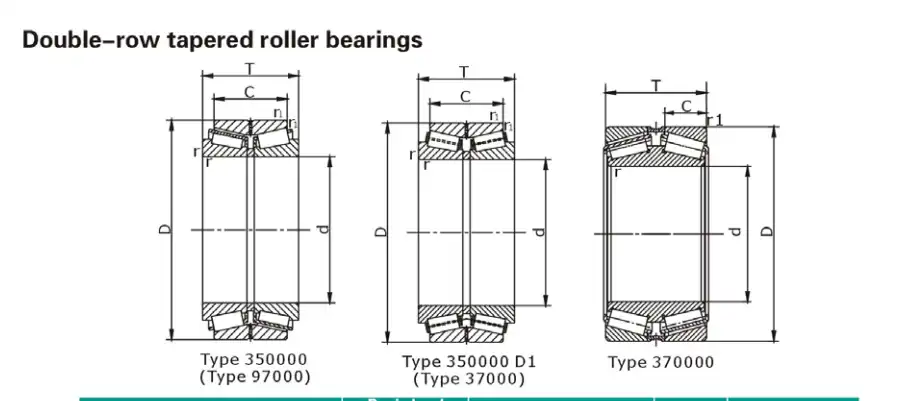

4. Our double row tapered roller bearings are produced in two configurations and in several different designs:

The performance of type TDO bearing is the same as two single-two tapered roller bearings in back to back mounted.

Type TDI bearing is mainly used in roll necks with medium loads. This type of bearings have a cup spacer, and the clearance is asjustable

5. Size range: Inter diameter:150-1778mm

6. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

What is a Double Row Tapered Roller Bearing?

A Double Row Tapered Roller Bearing is a type of bearing that is designed to handle heavy radial and axial loads simultaneously. This bearing features two rows of tapered rollers arranged in a way that they converge at a single point on the axis of the bearing.

Why Choose CHG Bearing?

At CHG Bearing, we pride ourselves on being a leading manufacturer and supplier of the products. Here’s why you should consider us for your bearing needs:

- Durability: These bearings are built to last, offering long service life even in harsh operating conditions.

- Precision and Reliability: The tapered roller design ensures accurate alignment and smooth operation, reducing the risk of equipment failure.

- Versatility: Suitable for various applications in metallurgy, mining, and heavy machinery, making them a flexible choice for different industries.

For more information or inquiries, feel free to contact us at sale@chg-bearing.com.

Technical Specifications

| Specification | Details |

|---|---|

| Bore Diameter | Customizable based on requirements |

| Outer Diameter | Customizable based on requirements |

| Width | Customizable based on requirements |

| Dynamic Load Rating | Varies based on size and design |

| Static Load Rating | Varies based on size and design |

| Material | High-quality steel / stainless steel or customized materials |

| Lubrication | Grease or oil, depending on the application |

| Temperature Range | -40°C to 120°C (customizable) |

Applications

Double Row Tapered Roller Bearing is widely used in:

- Metallurgical Equipment: Blast furnaces, rolling mills, and steelmaking equipment.

- Mining Machinery: Jaw crushers, impact crushers, vibrating screens, and feeders.

- Industrial Machinery: Heavy-duty equipment requiring high load capacity and precision.

Installation Guide

- Preparation: Ensure the bearing and housing are clean and free from contaminants.

- Alignment: Properly align the bearing with the shaft and housing to prevent uneven load distribution.

- Mounting: Use appropriate tools to press the bearing into place, ensuring a snug fit.

- Lubrication: Apply the recommended lubricant based on the application and operating conditions.

- Testing: Rotate the bearing manually to check for smooth operation and alignment before starting the machinery.

Maintenance and Care

- Regular Inspection: Check for signs of wear, such as noise or vibration, and address issues promptly.

- Lubrication: Keep bearings well-lubricated according to the manufacturer’s recommendations to prevent premature failure.

- Cleaning: Regularly clean the bearing and its surroundings to avoid contamination.

- Temperature Monitoring: Ensure the operating temperature is within the specified range to avoid overheating.

Our Certification

FAQ

1. What makes Double Row Tapered Roller Bearings different from single row bearings?

Double-tapered Tapered Roller Bearings can handle both radial and axial loads simultaneously due to their design, making them suitable for more demanding applications compared to single row bearings.

2. Can these bearings be customized?

Yes, CHG Bearing offers customization options for size, material, and lubrication methods to meet specific application requirements.

3. What industries commonly use the products?

They are commonly used in metallurgy, mining, and heavy industrial machinery, where high load capacity and durability are crucial.

4. How often should these bearings be maintained?

Regular maintenance is recommended based on operating conditions. Typically, bearings should be inspected and lubricated regularly to ensure optimal performance and longevity.

Customer Reviews

1. John M., Production Manager: "CHG Bearing's products have significantly improved the reliability of our equipment. Their customization options and prompt service are top-notch."

2. Sara L., Technical Engineer: "The precision and durability of these bearings are impressive. We’ve had great results in our heavy machinery applications."

Contact Us

For more information about our Double Row Tapered Roller Bearing or to request a quote, please reach out to us Email: sale@chg-bearing.com

At CHG Bearing, we are dedicated to providing high-quality bearings and exceptional service. Let us help you find the perfect solution for your needs!

| Boundary dimensions | Basic load ratings | Part number | Mass | Limiting speeds | ||||||||

| mm | kN | Current | Original | kg | r/min | |||||||

| d | D | T | C | rmin | r1min | Cr | Cor | Grease | Oil | |||

| 150 | 210 | 86 | 70 | 2.5 | 1 | 419 | 887 | 352930 | 2097930E | 8.5 | 900 | 1300 |

| 250 | 138 | 112 | 2.5 | 1 | 858 | 1620 | 352130 | 2097730 | 26 | 850 | 1100 | |

| 270 | 164 | 130 | 4 | 1 | 1250 | 2250 | 352230 | 97530E | 38 | 800 | 1000 | |

| 270 | 172 | 138 | 4 | 1 | 1250 | 2250 | 352230X2 | 97530 | 38 | 800 | 1000 | |

| 160 | 240 | 115 | 90 | 3 | 1 | 641 | 1400 | 352032X2 | 2097132 | 14.9 | 850 | 1100 |

| 270 | 150 | 120 | 3 | 1 | 1050 | 2030 | 352132 | 2097732 | 32.5 | 800 | 1000 | |

| 290 | 178 | 144 | 4 | 1 | 1400 | 2730 | 352232 | 97532E | 49 | 700 | 900 | |

| 170 | 260 | 120 | 95 | 3 | 1 | 672 | 1460 | 352034X2 | 2097134 | 21 | 800 | 1000 |

| 180 | 280 | 134 | 108 | 3 | 1 | 952 | 1880 | 352036X2 | 2097136 | 29 | 670 | 850 |

| 280 | 142 | 110 | 3 | 1 | 952 | 1880 | 352036 | 2097136E | 28.5 | 800 | 1000 | |

| 300 | 164 | 134 | 3 | 1 | 1290 | 2540 | 352136 | 2097736 | 44 | 670 | 850 | |

| 320 | 192 | 152 | 5 | 1.1 | 1750 | 3350 | 352236 | 97536E | 62.5 | 600 | 750 | |

| 190 | 289.5 | 100 | 40 | 3 | 3 | 750 | 1500 | 372038 | - | 27 | 700 | 900 |

| 320 | 170 | 130 | 3 | 1 | 1440 | 2800 | 352138 | 2097738 | 51 | 670 | 850 | |

| 200 | 280 | 116 | 92 | 3 | 1 | 758 | 1423 | 352940X2/YA | 2097940EK | 14.8 | 700 | 900 |

| 280 | 105 | 80 | 3 | 1 | 650 | 2660 | 352940X2 | 2097940 | 18.5 | 700 | 900 | |

| 310 | 152 | 120 | 2.5 | 1.1 | 1180 | 2720 | 352040X2 | 2097140 | 41 | 670 | 850 | |

| 340 | 184 | 150 | 3 | 1 | 1680 | 3340 | 352140 | 2097740 | 64 | 670 | 850 | |

| 360 | 218 | 174 | 5 | 1.1 | 2310 | 4250 | 352240 | 97540E | 90.5 | 600 | 750 | |

| 220 | 300 | 110 | 88 | 3 | 1.2 | 660 | 1710 | 352944X2 | 2097944 | 21.2 | 670 | 850 |

| 340 | 165 | 130 | 4 | 1 | 1360 | 2790 | 352044X2 | 2097144 | 47.7 | 600 | 750 | |

| 370 | 195 | 150 | 4 | 1.1 | 1740 | 3450 | 352144 | 2097744 | 76.3 | 600 | 750 | |

| 230 | 355 | 145 | 110 | 6 | 3 | 1060 | 2040 | 350646D1 | 37746 | 43.6 | 600 | 750 |

| 240 | 320 | 116 | 92 | 3 | 1 | 820 | 1910 | 352948 | 2097948E | 22.3 | 600 | 750 |

| 320 | 110 | 90 | 3 | 1.5 | 820 | 1910 | 352948X2 | 2097948 | 23 | 600 | 750 | |

| 360 | 165 | 130 | 4 | 1 | 1370 | 3180 | 352048X2 | 2097148 | 52.8 | 530 | 670 | |

| 360 | 166 | 128 | 4 | 1 | 1370 | 3180 | 352048 | 2097148E | 55.6 | 530 | 670 | |

| 260 | 360 | 134 | 52 | 3.5 | 2.5 | 1150 | 2300 | 372952K | - | 43.5 | 530 | 670 |

| Boundary dimensions | Basic load ratings | Part number | Mass | Limiting speeds | ||||||||

| mm | kN | Current | Original | kg | r/min | |||||||

| d | D | T | C | rmin | r1min | Cr | Cor | Grease | Oil | |||

| 260 | 360 | 134 | 108 | 3 | 1 | 1263 | 2430 | 352952X2 | 2097952 | 36.8 | 530 | 670 |

| 400 | 150 | 110 | 6 | 1.5 | 1240 | 2330 | - | 37852 | 60.3 | 530 | 670 | |

| 400 | 186 | 146 | 5 | 1.1 | 1780 | 3830 | 352052X2 | 2097152 | 76.8 | 500 | 630 | |

| 400 | 190 | 146 | 5 | 1.1 | 1780 | 3830 | 352052 | 2097152E | 79.5 | 500 | 630 | |

| 430 | 180 | 130 | 10 | 3 | 2100 | 2800 | 350652D1 | 37752 | 87.9 | 500 | 630 | |

| 430 | 180 | 130 | 7.5 | 1.5 | 2237 | 3016 | 350652 | 97752 | 93.4 | 500 | 630 | |

| 440 | 225 | 180 | 4 | 1.1 | 2480 | 5050 | 352152 | 2097752 | 124 | 450 | 560 | |

| 280 | 380 | 134 | 108 | 3 | 1.1 | 1080 | 2810 | 352956X2 | 2097956 | 41.3 | 480 | 600 |

| 420 | 133 | 106 | 4 | 2 | 1270 | 1936 | 351056 | 97156 | 58.1 | 450 | 560 | |

| 420 | 186 | 146 | 5 | 1.1 | 1860 | 4000 | 352056X2 | 2097156 | 81.5 | 450 | 560 | |

| 300 | 420 | 160 | 128 | 4 | 1.1 | 1470 | 3530 | 352960X2 | 2097960 | 64 | 450 | 560 |

| 460 | 210 | 165 | 4 | 1.5 | 2200 | 4940 | 352060X2 | 2097160 | 118 | 430 | 530 | |

| 500 | 205 | 152 | 5 | 1.5 | 2200 | 4500 | 351160 | 1097760 | 144 | 400 | 500 | |

| 320 | 440 | 160 | 128 | 4 | 1.5 | 1410 | 3830 | 352964X2 | 2097964 | 67 | 430 | 530 |

| 480 | 210 | 84 | 5 | 4 | 2340 | 6130 | 372064X2 | - | 133 | 400 | 500 | |

| 480 | 210 | 160 | 5 | 1.1 | 1830 | 4390 | 352064X2 | 2097164 | 122 | 400 | 500 | |

| 340 | 460 | 160 | 128 | 4 | 1 | 1575 | 4050 | 352968X2 | 2097968 | 71 | 400 | 500 |

| 520 | 180 | 135 | 5 | 1.5 | 1904 | 4070 | 351068 | 97168 | 119 | 380 | 480 | |

| 580 | 242 | 170 | 5 | 1.5 | 2870 | 5970 | 351168 | 1097768 | 214 | 340 | 430 | |

| 350 | 590 | 200 | 140 | 9.5 | 1.5 | 2800 | 5500 | 350670 | 97770 | 212 | 320 | 400 |

| 360 | 480 | 160 | 128 | 4 | 1 | 1490 | 4270 | 352972X2 | 2097972 | 74.3 | 380 | 480 |

| 530 | 155 | 110 | 5 | 1.5 | 1690 | 3300 | 350672D1 | 37772 | 109 | 380 | 480 | |

| 530 | 155 | 110 | 5 | 1.5 | 1690 | 3300 | 350672 | 97772 | 107 | 380 | 480 | |

| 540 | 169 | 134 | 6 | 2 | 1980 | 3950 | 351072X2 | 97872 | 122 | 340 | 430 | |

| 540 | 185 | 140 | 5 | 1.5 | 2120 | 4910 | 351072 | 97172 | 127 | 360 | 450 | |

| 600 | 242 | 170 | 5 | 1.5 | 2950 | 6270 | 351172 | 1097772 | 235 | 320 | 400 | |

| 379 | 681.5 | 307 | 118 | 2.5 | 6 | 5600 | 11700 | 3706/379 | - | 512 | 300 | 380 |

| Boundary dimensions | Basic load ratings | Part number | Mass | Limiting speeds | ||||||||

| mm | kN | Current | Original | kg | r/min | |||||||

| d | D | T | C | rmin | r1min | Cr | Cor | Grease | Oil | |||

| 380 | 520 | 145 | 105 | 4 | 1.1 | 1210 | 3250 | 351976 | 1097976 | 80.3 | 360 | 450 |

| 560 | 190 | 140 | 5 | 1.5 | 2150 | 5090 | 351076 | 97176 | 146 | 340 | 430 | |

| 620 | 242 | 170 | 5 | 1.5 | 3310 | 7430 | 351176 | 1097776 | 243 | 300 | 380 | |

| 400 | 540 | 150 | 105 | 4 | 1.1 | 1210 | 3110 | 351980 | 1097980 | 86.9 | 320 | 400 |

| 590 | 185 | 123 | 5 | 2 | 2710 | 5950 | 350180D | 37780 | 166 | 320 | 400 | |

| 600 | 206 | 150 | 5 | 1.5 | 2620 | 6380 | 351080 | 97180 | 180 | 300 | 380 | |

| 420 | 560 | 145 | 105 | 4 | 1.1 | 1450 | 3740 | 351984 | 1097984 | 88.7 | 300 | 380 |

| 620 | 190 | 125 | 5 | 1 | 2450 | 5700 | 350184D | 37784 | 171 | 280 | 360 | |

| 620 | 206 | 150 | 5 | 1.5 | 2650 | 6600 | 351084 | 97184 | 187 | 280 | 360 | |

| 700 | 275 | 200 | 6 | 2.5 | 4270 | 8810 | 351184 | 1097784 | 392 | 240 | 340 | |

| 440 | 600 | 170 | 125 | 4 | 1.1 | 1890 | 4860 | 351988 | 1097988 | 114 | 280 | 360 |

| 650 | 212 | 152 | 6 | 2.5 | 2750 | 7020 | 351088 | 97188 | 213 | 260 | 340 | |

| 460 | 620 | 174 | 130 | 4 | 1.1 | 1910 | 4990 | 351992 | 1097992 | 130 | 260 | 340 |

| 680 | 230 | 175 | 6 | 2.5 | 2680 | 5900 | 351092 | 97192 | 253 | 220 | 300 | |

| 480 | 650 | 180 | 130 | 5 | 1.5 | 1950 | 5270 | 351996 | 1097996 | 151 | 240 | 320 |

| 700 | 240 | 180 | 6 | 2.5 | 3330 | 8190 | 351096 | 97196 | 281 | 200 | 280 | |

| 490 | 640 | 180 | 144 | 7.5 | 3 | 2290 | 6600 | 350698 | 97798 | 140 | 220 | 300 |

| 500 | 670 | 180 | 130 | 5 | 1.5 | 2150 | 6120 | 3519/500 | 10979/500 | 159 | 220 | 300 |

| 720 | 236 | 180 | 6 | 2.5 | 3390 | 8450 | 3510/500 | 971/500 | 289 | 190 | 260 | |

| 520 | 740 | 190 | 120 | 2.5 | 2.5 | 2780 | 6800 | 3506/520 | 977/520 | 231 | 190 | 260 |

| 530 | 710 | 190 | 136 | 5 | 1.5 | 2390 | 6800 | 3519/530 | 10979/530 | 190 | 190 | 260 |

| 730 | 250 | 106 | 6 | 6 | 5350 | 14800 | 3706/530 | - | 354 | 160 | 200 | |

| 560 | 750 | 213 | 156 | 5 | 1.5 | 2550 | 7060 | 3519/560 | 10979/560 | 235 | 170 | 220 |

| 820 | 260 | 185 | 6 | 2.5 | 4340 | 10800 | 3510/560 | 971/560 | 409 | 160 | 200 | |

| 600 | 800 | 205 | 156 | 5 | 1.5 | 3210 | 9460 | 3519/600 | 10979/600 | 266 | 150 | 190 |

| 870 | 270 | 198 | 6 | 2.5 | 4880 | 12730 | 3510/600 | 971/600 | 500 | 130 | 170 | |

| Boundary dimensions | Basic load ratings | Part number | Mass | Limiting speeds | ||||||||

| mm | kN | Current | Original | kg | r/min | |||||||

| d | D | T | C | rmin | r1min | Cr | Cor | Grease | Oil | |||

| 630 | 850 | 242 | 182 | 6 | 2.5 | 3730 | 10390 | 3519/630 | 10979/630 | 368 | 130 | 170 |

| 670 | 900 | 240 | 180 | 6 | 2.5 | 5300 | 12300 | 3519/670 | 10979/670 | 416 | 120 | 160 |

| 710 | 950 | 240 | 175 | 6 | 2.5 | 4070 | 12400 | 3519/710X2 | 10979/710 | 444 | 100 | 140 |

| 1030 | 236 | 208 | 7.5 | 4 | 5750 | 14300 | 3506/710 | 977/710 | 651 | 90 | 120 | |

| 1030 | 315 | 220 | 7.5 | 3 | 7830 | 18400 | 3510/710 | 971/710 | 774 | 90 | 120 | |

| 720 | 915 | 190 | 140 | 3 | 6 | 3200 | 9650 | 3506/720 | 977/720 | 277 | 100 | 140 |

| 750 | 1000 | 264 | 194 | 6 | 2.5 | 5020 | 14480 | 3519/750 | 10979/750 | 499 | 90 | 120 |

| 800 | 1060 | 270 | 204 | 6 | 2.5 | 5020 | 15000 | 3519/800 | 10979/800 | 604 | 80 | 100 |

| 850 | 1120 | 268 | 188 | 6 | 2.5 | 5460 | 16860 | 3519/850 | 10979/850 | 636 | 75 | 95 |

| 950 | 1250 | 300 | 220 | 7.5 | 3 | 6790 | 21100 | 3519/950 | 10979/950 | 909 | - | - |

| 1120 | 1480 | 400 | 296 | 12 | 4 | 12060 | 34200 | BT2B 332756 | - | 1760 | - | - |

| 1160 | 1540 | 400 | 290 | 12 | 4 | 12780 | 34200 | BT2B 332780 | - | 1900 | - | - |

| 1250 | 1500 | 250 | 190 | 6 | 1.5 | 6633 | 20160 | BT2B 328339 | - | 795 | - | - |

| 1778 | 2159 | 393.7 | 266.7 | 12.7 | 3 | 13860 | 47700 | BT2B 332496 | - | 2750 | - | - |