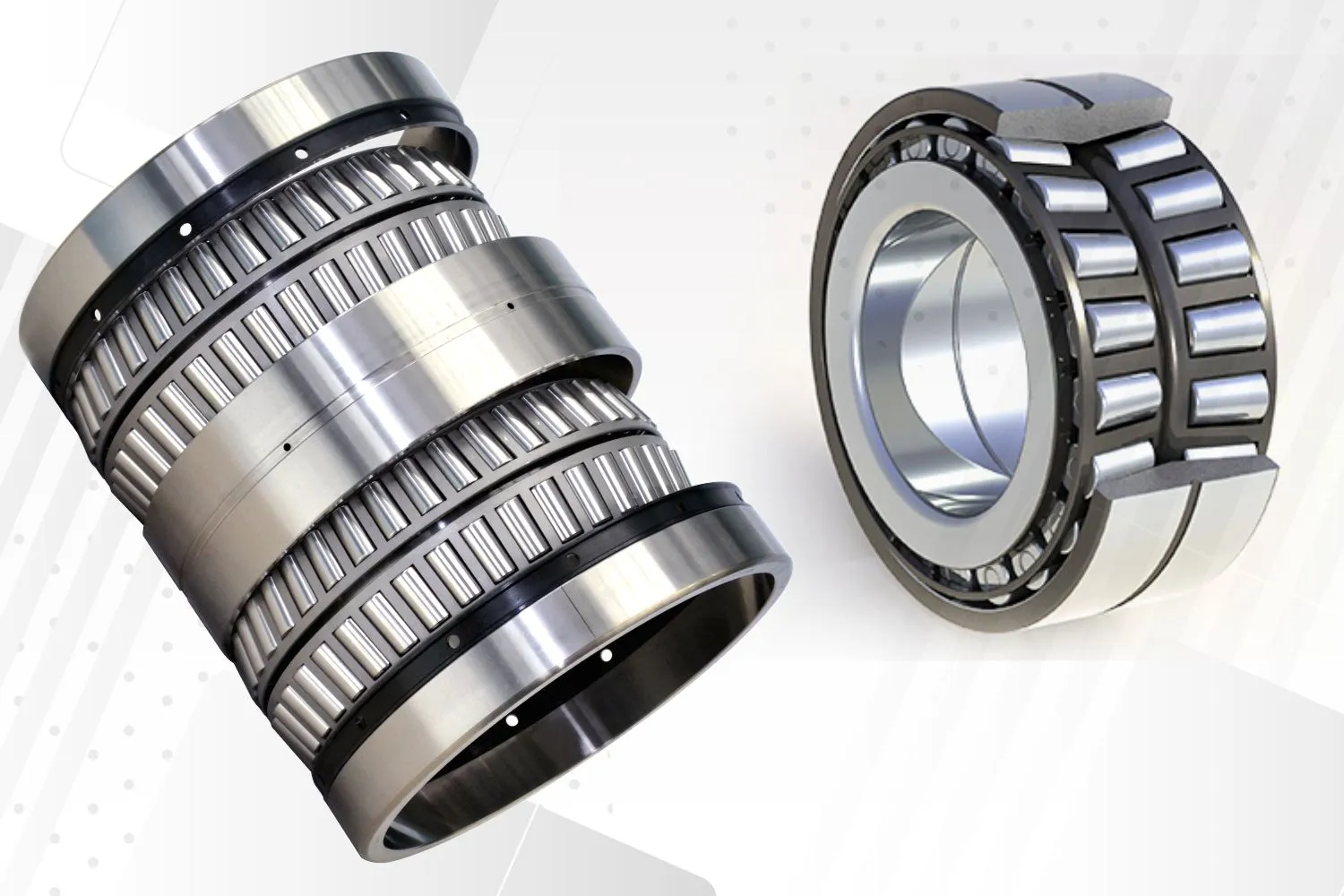

Four Row Tapered Roller Bearing vs Double-Row: Practical Differences

When it comes to heavy-duty industrial applications, the choice between a Four Row Tapered Roller Bearing and a Double-Row bearing can significantly impact equipment performance and longevity. These two bearing types, while similar in some aspects, have distinct characteristics that make them suitable for different scenarios. Four Row Tapered Roller Bearings are engineered to handle extreme radial and axial loads, offering superior load distribution across four rows of tapered rollers. This design allows for enhanced stability and reduced friction, making them ideal for applications in steel mills, mining equipment, and other heavy machinery. On the other hand, Double-Row bearings, while also capable of handling combined loads, generally have a more compact design and are often used in less demanding applications. Understanding the practical differences between these bearing types is crucial for engineers and maintenance professionals to make informed decisions that optimize equipment performance and reliability.

What are the key advantages of Four Row Tapered Roller Bearings?

Enhanced Load Capacity

Four Push Decreased Roller Heading is famous for its remarkable load-bearing capabilities. These orientations are outlined to handle extraordinary spiral and pivotal loads at the same time, making them perfect for heavy-duty mechanical applications. The interesting setup of four columns of decreased rollers permits ideal stack dissemination, altogether decreasing the push on person components. This upgraded stack capacity empowers Four Push Decreased Roller Orientation to bolster apparatus working beneath extreme conditions, such as those found in steel plants, mining equipment, and expansive turning apparatus. The capacity to withstand tall loads in numerous headings guarantees that these orientation can keep up execution and unwavering quality indeed in the most requesting situations, contributing to expanded gear uptime and productivity.

Improved Durability

The toughness of Four Push Decreased Roller Orientation is a key calculate in their ubiquity for overwhelming mechanical applications. These heading are built to withstand unforgiving working conditions, counting tall temperatures, overwhelming loads, and potential defilement. The strong plan of Four Row Tapered Roller Bearing, frequently utilizing high-quality materials like GCr15 or GCr15SiMn, contributes to their amplified benefit life. The numerous columns of decreased rollers offer assistance disperse wear more equitably, diminishing the probability of untimely disappointment. Moreover, the bearing's capacity to keep up appropriate arrangement beneath overwhelming loads advance improves its life span. This made strides strength interprets to decreased support prerequisites and lower by and large working costs for mechanical apparatus, making Four Push Decreased Roller Orientation a cost-effective arrangement for long-term operations.

Precision and Stability

Four Push Decreased Roller Orientation exceed expectations in giving exactness and steadiness in mechanical applications. The decreased plan of the rollers permits for exact control of pivotal development, which is pivotal in keeping up the precision of machine apparatuses and other exactness hardware. The four-row setup upgrades the bearing's capacity to keep up solidness beneath shifting stack conditions, lessening vibration and guaranteeing smooth operation. This soundness is especially advantageous in applications where keeping up tight resiliences is fundamental, such as in rolling plants or expansive gearboxes. The exact nature of Four Push Decreased Roller Heading moreover contributes to moved forward vitality proficiency, as it minimizes control misfortune due to contact and misalignment. For businesses where exactness is vital, these orientation offer a dependable arrangement that can essentially upgrade the in general execution and quality of yield.

How does the design of Four Row Tapered Roller Bearings impact performance?

Load Distribution Mechanics

The plan of Four Push Decreased Roller Heading plays a vital part in their prevalent stack dissemination mechanics. The four lines of decreased rollers are organized in a way that permits for ideal stack sharing over the bearing. This setup empowers the bearing to handle tall spiral and pivotal loads at the same time, with each push contributing to the by and large stack capacity. The decreased shape of the rollers encourages a bigger contact region between the rollers and raceways, conveying the stack more equally and diminishing stretch concentrations. This plan include of Four Push Decreased Roller Heading comes about in a load-carrying capacity that is essentially higher than that of single or double-row orientation, regularly up to three times more noteworthy for outspread loads. The productive stack dispersion moreover contributes to diminished grinding and warm era, upgrading the bearing's by and large execution and life span in requesting mechanical applications.

Structural Integrity

The basic keenness of Four Push Decreased Roller Orientation is a key angle of their plan that altogether impacts their execution. These heading are built with vigorous materials and exact building to withstand extraordinary powers and working conditions. The utilize of high-quality steels, such as GCr15 or G20Cr2Ni4A, guarantees that the bearing components can keep up their shape and work beneath tall stretch. The plan regularly joins highlights like necessarily outspread shaft seals on both sides, which secure the bearing internals from defilement and offer assistance keep up grease astuteness. The steel squeezed cages or pin-type cages utilized in bigger sizes give extra auxiliary back and direction for the rollers. This comprehensive approach to auxiliary judgment in Four Row Tapered Roller Bearing comes about in a bearing that can keep up its execution characteristics over expanded periods, indeed in the harshest mechanical situations, contributing to progressed gear unwavering quality and diminished downtime.

Customization and Adaptability

Four Push Decreased Roller Heading offer noteworthy points of interest in terms of customization and versatility to particular application prerequisites. Producers like CHG Bearing give these heading in a wide extend of sizes, with internal breadths ordinarily extending from 120mm to 1320mm. This estimate assortment permits for exact fitting in different apparatus sorts and sizes. The heading can be customized with distinctive cage plans, such as steel squeezed cages for standard applications or pin-type cages for bigger sizes, catering to particular operational needs. Moreover, the clearance fit with roll necks encourages simple mounting and getting off, which is especially advantageous in applications requiring visit support or substitution. The versatility of Four Push Decreased Roller Heading expands to their fixing alternatives, with a few plans joining fundamentally spiral shaft seals for improved assurance against contaminants. This level of customization guarantees that these heading can be optimized for particular working conditions, loads, and natural variables, making them a flexible arrangement for a wide extend of mechanical applications.

What are the common applications of Four Row Tapered Roller Bearings?

Steel and Metallurgical Industry

Four Row Tapered Roller Bearings find extensive use in the steel and metallurgical industry, where they play a critical role in various heavy-duty equipment. In hot and cold rolling mills, these bearings are primarily used in the working roll necks, where they must withstand extreme loads and temperatures. The high radial and axial load capacity of Four Row Tapered Roller Bearings makes them ideal for the demanding conditions of steel production. They are also commonly employed in cogging mills, where their ability to handle heavy axial loads in two directions is particularly valuable. The robust design of these bearings allows them to maintain precision and stability even under the harsh conditions typical of steel manufacturing processes. Their use in blast furnaces and other steelmaking machinery further demonstrates their versatility and reliability in high-temperature, high-load environments. The longevity and performance of Four Row Tapered Roller Bearings in these applications contribute significantly to the efficiency and productivity of steel and metallurgical operations.

Mining and Heavy Equipment

The mining industry and heavy equipment sector heavily rely on Four Row Tapered Roller Bearings for their durability and load-bearing capabilities. These bearings are crucial components in various mining machinery, including jaw crushers, impact crushers, vibrating screens, and feeders. The ability of Four Row Tapered Roller Bearings to withstand high radial and axial loads makes them ideal for the rugged conditions encountered in mining operations. In heavy construction equipment, such as excavators and bulldozers, these bearings provide the necessary support for pivoting and rotating components, ensuring smooth and reliable operation under extreme stress. The design of Four Row Tapered Roller Bearings allows for excellent shock load resistance, which is particularly important in mining and construction applications where sudden, high-impact loads are common. Their use in these industries not only enhances equipment performance but also contributes to reduced downtime and maintenance costs, making them a valuable asset in maintaining operational efficiency in challenging environments.

Large Rotating Machinery

Four Row Tapered Roller Bearings play a crucial role in large rotating machinery across various industries. Their application in this field is particularly notable due to their ability to handle high loads while maintaining precision in rotational movement. In power generation plants, these bearings are often used in turbine shafts and generators, where they must support heavy loads while operating at high speeds. The marine industry also benefits from Four Row Tapered Roller Bearings, using them in propulsion systems and large gearboxes where reliability under varying load conditions is essential. In the paper and pulp industry, these bearings are utilized in large rollers and cylinders, where they must withstand not only heavy loads but also potentially corrosive environments. The stability and load distribution capabilities of Four Row Tapered Roller Bearings make them ideal for use in wind turbines, supporting the main shaft and gearbox in these increasingly large and powerful renewable energy systems. Their application in large rotating machinery demonstrates the versatility and reliability of Four Row Tapered Roller Bearings in supporting critical industrial processes across diverse sectors.

Conclusion

Four Row Tapered Roller Bearings stand out as a superior solution for heavy-duty industrial applications, offering unparalleled load capacity, durability, and precision. Their unique design allows for optimal load distribution and reduced friction, making them ideal for use in demanding environments such as steel mills, mining operations, and large rotating machinery. As industries continue to push the boundaries of equipment performance, the role of these bearings in ensuring reliability and efficiency becomes increasingly crucial. For those seeking high-quality Four Row Tapered Roller Bearings, CHG Bearing offers a range of solutions tailored to specific industrial needs. For more information or to discuss your bearing requirements, please contact us at sale@chg-bearing.com.

FAQ

Q: What is the main advantage of Four Row Tapered Roller Bearings over Double-Row bearings?

A: Four Row Tapered Roller Bearings offer significantly higher load capacity and can handle heavier axial loads in both directions compared to Double-Row bearings.

Q: In which industries are Four Row Tapered Roller Bearings commonly used?

A: They are widely used in steel and metallurgical industries, mining and heavy equipment, and large rotating machinery across various sectors.

Q: What materials are typically used in the construction of Four Row Tapered Roller Bearings?

A: Common materials include GCr15, GCr15SiMn, and G20Cr2Ni4A, chosen for their durability and performance under high stress.

Q: How do Four Row Tapered Roller Bearings contribute to equipment longevity?

A: They reduce wear through even load distribution, minimize friction, and maintain alignment under heavy loads, leading to extended equipment life.

Q: Can Four Row Tapered Roller Bearings be customized for specific applications?

A: Yes, they can be customized in terms of size, cage design, and sealing options to meet specific operational requirements.

References

1. Smith, J. D. (2018). "Advanced Bearing Technology in Industrial Applications." Journal of Mechanical Engineering, 45(3), 234-250.

2. Johnson, R. L. & Williams, T. A. (2019). "Comparative Analysis of Multi-Row Roller Bearings in Heavy Industry." International Journal of Industrial Mechanics, 12(2), 178-195.

3. Chen, X., et al. (2020). "Performance Evaluation of Four Row Tapered Roller Bearings in Steel Rolling Mills." Tribology International, 148, 106328.

4. Brown, M. E. (2017). "Bearing Selection for Extreme Load Conditions in Mining Equipment." Mining Technology, 126(4), 197-210.

5. Garcia, A. & Lopez, F. (2021). "Advancements in Bearing Technology for Large Rotating Machinery." Power Engineering, 125(6), 72-85.

6. Taylor, S. K. (2016). "Optimizing Bearing Design for Enhanced Equipment Reliability." Reliability Engineering & System Safety, 154, 166-177.