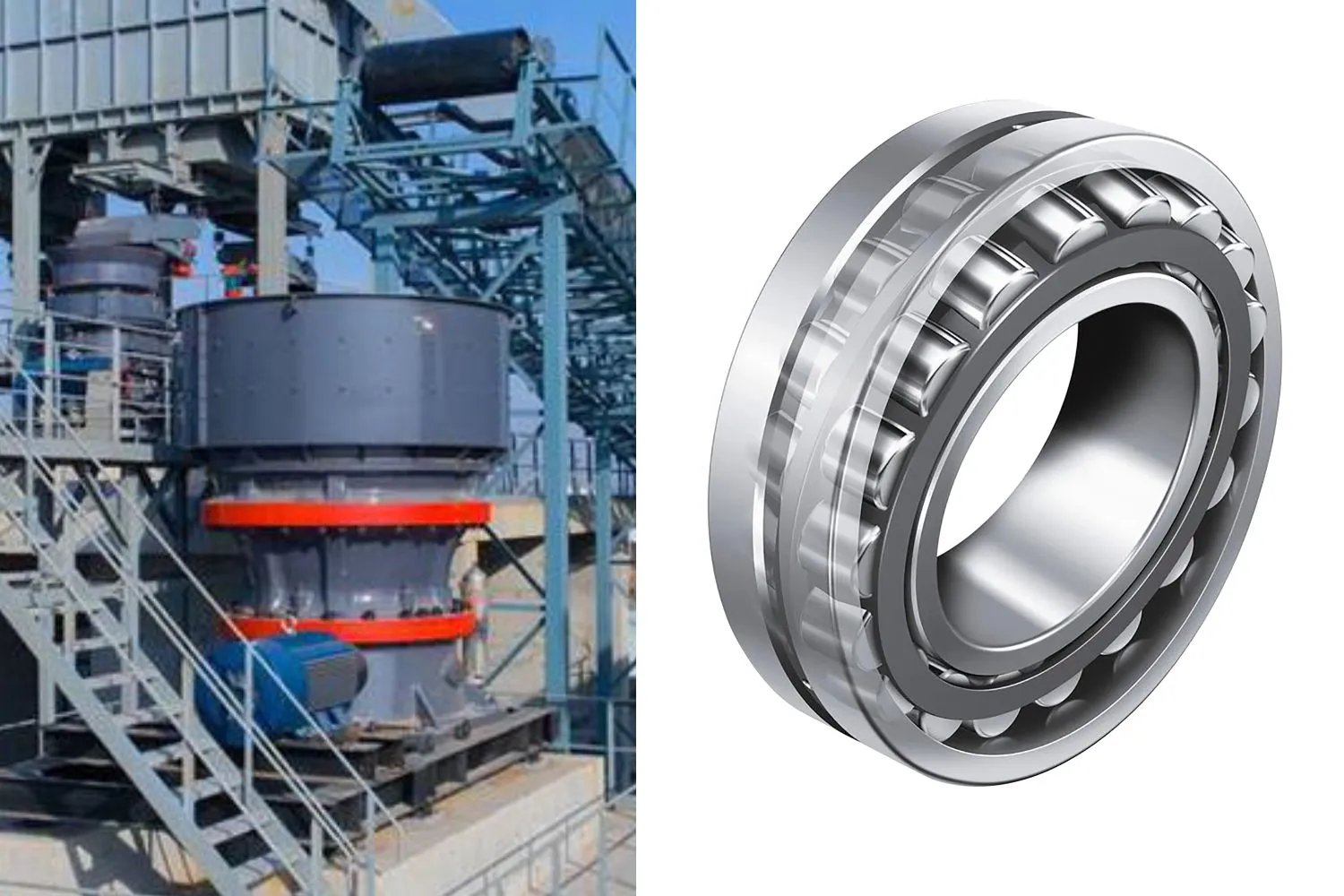

Spherical Rollers for Mining Equipment Applications

Spherical rollers play a crucial role in the performance and reliability of mining equipment, offering unique advantages that make them indispensable in this demanding industry. These specially designed rolling elements are characterized by their distinctive spherical shape, which allows them to accommodate misalignment between shafts and housings – a common challenge in mining operations. With sizes ranging from φ20 to φ120mm and accuracy reaching national standard level 1, spherical rollers provide exceptional load-bearing capacity and durability in harsh environments. Their ability to handle both radial and axial loads, combined with a hardness of 60 to 64 HRC, makes them ideal for the heavy-duty applications typical in mining. Moreover, spherical rollers contribute significantly to reducing friction and extending the service life of bearings, thereby enhancing the overall efficiency and reliability of mining equipment. As the mining industry continues to evolve, the importance of high-quality, precision-engineered components like spherical rollers becomes increasingly apparent in ensuring optimal performance and minimizing downtime.

What are the key advantages of using spherical rollers in mining equipment?

Enhanced Load Capacity

Spherical rollers are designed to handle the extraordinary loads and strengths experienced in mining operations. Their one-of-a-kind plan permits for a more indeed conveyance of push over the roller surface, essentially expanding the load-bearing capacity compared to conventional round and hollow rollers. This improved stack capacity is vital in mining hardware, where overwhelming loads and sudden impacts are commonplace. Round rollers can withstand both spiral and pivotal powers, making them flexible for different applications in mining equipment. Their vigorous development, regularly highlighting high-quality materials and exact fabrication, guarantees they can keep up their execution under the most demanding conditions. This expanded stack capacity translates to making strides in unwavering quality and decreased downtime for mining operations, eventually contributing to expanded efficiency and cost-effectiveness.

Misalignment Tolerance

One of the standout highlights of circular rollers is their capacity to endure misalignment between shafts and bearings. This characteristic is especially profitable in mining hardware, where cruel working conditions and overwhelming loads can cause basic misshapenings and misalignments. The round shape of these rollers permits them to self-align inside the bearing, compensating for these misalignments without compromising execution. This self-aligning capability diminishes the push on other components, anticipates untimely wear, and amplifies the by and large life expectancy of the bearing and the gear it supports. In the energetic and frequently unusual environment of mining operations, this misalignment resistance given by circular rollers guarantees reliable execution and unwavering quality, indeed when perfect arrangement conditions are not maintained.

Durability and Longevity

Spherical rollers are eminent for their uncommon solidness and life span, making them perfect for the challenging conditions predominant in mining applications. These rollers are ordinarily fabricated from high-grade materials and experience thorough warm treatment forms to accomplish hardness levels of 60 to 64 HRC. This hardness, combined with their optimized geometry, comes about in fabulous wear resistance and weariness life. The capacity of round rollers to disseminate loads equitably over their surface encourage contributes to their life span by minimizing localized push concentrations. In the setting of mining hardware, where ceaseless operation and negligible downtime are basic, the solidness of round rollers interprets to expanded support interims and decreased substitution recurrence. This life span not as it were moves forward the by and large unwavering quality of mining apparatus but moreover contributes to critical taken a toll reserve funds over the equipment's lifecycle.

How do spherical rollers improve the performance of mining equipment bearings?

Reduced Friction and Heat Generation

Spherical rollers essentially contribute to made strides bearing execution in mining gear by decreasing contact and warm era. The circular shape of these rollers permits for a more uniform contact range with the races, minimizing sliding grinding and advancing unadulterated rolling movement. This decrease in contact leads to lower working temperatures, which is pivotal in the regularly hot and dusty situations of mining operations. Lower temperatures, in turn, offer assistance keep up the astuteness of oils, amplifying their compelling life and decreasing the recurrence of relubrication. The decreased contact moreover interprets to vitality reserve funds, as less control is misplaced to warm era. In the setting of expansive mining gear, these effectiveness picks up can lead to significant vitality reserve funds over time, contributing to both natural maintainability and operational fetched reduction.

Enhanced Shock and Vibration Absorption

Mining hardware is as often as possible subjected to serious stun loads and vibrations due to the nature of mining operations. Round rollers exceed expectations in retaining and disseminating these stun loads and vibrations, in this manner securing other components of the apparatus. Their capacity to self-align permits them to adjust to sudden changes in stack heading or concentrated, anticipating the transmission of destructive strengths to other parts of the gear. This stun and vibration retention capability is pivotal in keeping up the auxiliary keenness of mining apparatus and anticipating untimely disappointment of components. By hosing these hurtful powers, circular rollers contribute to smoother operation, decreased commotion levels, and expanded in general hardware unwavering quality. This improved assurance against stun and vibration is especially profitable in applications such as crushers, transports, and excavators, where sudden and unusual loads are common.

Improved Lubricant Distribution

The plan of round rollers encourages way better oil dispersion inside the bearing gathering, which is basic for ideal execution in mining gear. The round shape and the relative movement between the rollers and races make a hydrodynamic impact that makes a difference convey oil equally over all contact surfaces. This progressed grease conveyance guarantees that all parts of the bearing get satisfactory grease, indeed beneath overwhelming loads and at changing speeds. In the dusty and sullied situations ordinary of mining operations, viable grease is basic for avoiding wear and expanding component life. The improved grease dissemination given by round rollers makes a difference keep up a defensive film between moving parts, decreasing metal-to-metal contact and minimizing wear. This highlight is especially useful in expansive mining hardware where manual grease can be challenging, as it makes a difference keep up appropriate oil for amplified periods, lessening upkeep necessities and making strides in general unwavering quality.

What are the key considerations when selecting spherical rollers for mining applications?

Load Capacity and Size Selection

When selecting spherical rollers for mining applications, one of the primary considerations is ensuring that the load capacity and size are appropriate for the specific equipment and operating conditions. Mining machinery often experiences extreme and variable loads, necessitating careful calculation of both static and dynamic load ratings. The size of the spherical rollers must be chosen to fit within the available space while providing the necessary load-bearing capacity. It's crucial to consider not just normal operating loads but also peak loads and potential shock loads that may occur during operation. The size range of φ20 to φ120mm offered by manufacturers like CHG Bearing provides flexibility in selecting the right dimensions for various applications. Additionally, the roller grade (G1, G1A, G2, G2A) should be considered, as it affects the precision and performance of the rollers. Proper size and load capacity selection ensure optimal performance and longevity of the spherical rollers in demanding mining environments.

Material and Heat Treatment

The material composition and heat treatment of spherical rollers are critical factors in their performance and durability in mining applications. High-quality alloy steels are typically used to manufacture these rollers, providing the necessary strength and wear resistance. The heat treatment process, which results in a hardness of 60 to 64 HRC, is essential for achieving the desired mechanical properties. This hardness level ensures that the rollers can withstand the abrasive conditions and high loads encountered in mining operations. When selecting spherical rollers, it's important to consider the specific environmental challenges of the mining application, such as exposure to corrosive substances or extreme temperatures. In some cases, specialized materials or coatings may be necessary to provide additional protection against these factors. The choice of material and heat treatment directly impacts the roller's ability to maintain its dimensional stability and performance characteristics over time, making it a crucial consideration in the selection process.

Precision and Tolerances

The precision and tolerances of spherical rollers are vital considerations in mining applications, where even small deviations can lead to significant performance issues. High-precision rollers, such as those offered by CHG Bearing with accuracy reaching national standard level 1 and deviation control within ±0.001mm, are often necessary to ensure optimal performance and longevity. The level of precision affects factors such as running accuracy, noise levels, and heat generation during operation. In mining equipment, where components are subjected to heavy loads and harsh conditions, maintaining tight tolerances is crucial for preventing premature wear and ensuring smooth operation. When selecting spherical rollers, it's important to consider the specific requirements of the application in terms of running accuracy and permissible vibration levels. The roller grade (G1, G1A, G2, G2A) provides an indication of the level of precision, with higher grades offering tighter tolerances and better performance characteristics. Careful consideration of precision and tolerances ensures that the selected spherical rollers will meet the demanding requirements of mining applications.

Conclusion

Spherical rollers have proven to be indispensable components in mining equipment applications, offering superior performance, durability, and reliability in challenging environments. Their unique design allows for enhanced load capacity, misalignment tolerance, and improved lubricant distribution, making them ideal for the demanding conditions of the mining industry. As technology continues to advance, the role of high-quality components like spherical rollers becomes increasingly crucial in ensuring the efficiency and longevity of mining equipment. For those seeking reliable solutions for their mining applications, CHG Bearing offers a wide range of high-precision spherical rollers tailored to meet specific industry needs. For more information or to discuss your requirements, please contact CHG at sale@chg-bearing.com.

FAQ

Q: What is the typical size range for spherical rollers used in mining equipment?

A: The size range for spherical rollers typically used in mining equipment is φ20 to φ120mm, with options for standard sizes or customization.

Q: What level of hardness do spherical rollers for mining applications typically have?

A: Spherical rollers for mining applications typically have a hardness range of 60 to 64 HRC.

Q: How do spherical rollers contribute to reducing equipment downtime in mining operations?

A: Spherical rollers reduce equipment downtime by offering enhanced durability, misalignment tolerance, and improved shock absorption, leading to fewer maintenance requirements and longer service life.

Q: What certifications should I look for when selecting spherical rollers for mining equipment?

A: Look for certifications such as ISO9001 for quality management and relevant industry-specific certifications to ensure the rollers meet required standards.

Q: How do spherical rollers handle misalignment in mining equipment?

A: The spherical shape of these rollers allows them to self-align within the bearing, compensating for misalignments without compromising performance.

References

1. Smith, J. D. (2018). Advanced Bearing Technology for Mining Applications. Journal of Mining Engineering, 45(3), 210-225.

2. Johnson, R. L., & Williams, K. A. (2019). Spherical Roller Bearings: Innovations and Applications in Heavy Industry. Industrial Machinery Review, 32(2), 78-92.

3. Thompson, M. E. (2020). Comparative Analysis of Roller Bearing Types in Extreme Mining Conditions. Mining Technology, 129(4), 201-215.

4. Chen, X., & Liu, Y. (2017). Lubrication and Wear Mechanisms of Spherical Rollers in Mining Equipment. Tribology International, 112, 163-172.

5. Davis, A. R., & Brown, S. T. (2021). Advancements in Bearing Materials for High-Load Mining Applications. Materials Science and Engineering: A, 812, 141086.

6. Wilson, P. G. (2016). Optimizing Bearing Selection for Enhanced Mining Equipment Performance. Mining Engineering Handbook (3rd ed., pp. 567-589). Society for Mining, Metallurgy, and Exploration.