How do RB Cross Roller Bearings Work?

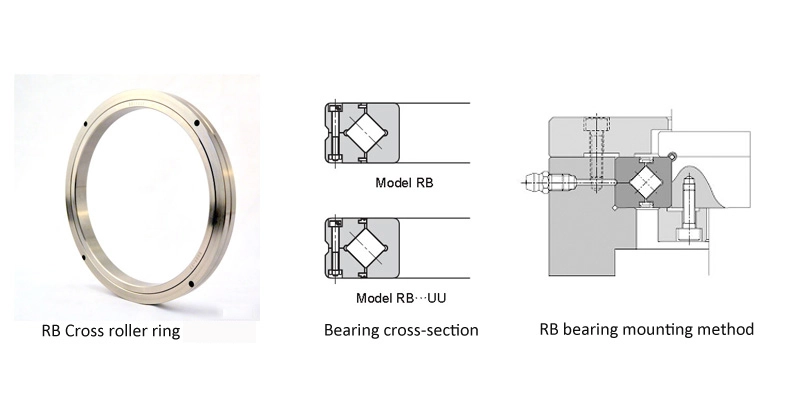

RB Cross Roller Bearings represent a sophisticated advancement in bearing technology, combining precision engineering with innovative design principles. These specialized bearings feature cylindrical rollers arranged in an alternating perpendicular pattern between two ring-shaped races. This unique configuration allows them to handle complex loads from multiple directions simultaneously, making them invaluable in applications requiring both high precision and robust load-bearing capabilities. The cross-arrangement of the rollers provides exceptional stability and accuracy, while the bearing's compact design offers significant space-saving advantages in various mechanical systems.

What Makes RB Cross Roller Bearings Different from Traditional Ball Bearings?

The fundamental distinction between RB Cross Roller Bearings and traditional ball bearings lies in their design philosophy and load-handling capabilities. Unlike conventional ball bearings that utilize spherical balls, cross roller bearings employ cylindrical rollers arranged in a perpendicular pattern. This unique configuration creates several significant advantages that set them apart from their traditional counterparts.

The cylindrical rollers provide substantially greater contact area with the bearing races compared to spherical balls. This increased contact surface results in superior load distribution and enhanced load-carrying capacity. For instance, when subjected to identical loads, a cross roller bearing typically demonstrates 3-4 times higher load-bearing capability than a similarly sized ball bearing. This characteristic makes them particularly valuable in applications where space is limited but load requirements are demanding.

Another crucial difference lies in their ability to handle complex loads. Traditional ball bearings often require separate components to manage different load directions effectively. In contrast, cross roller bearings can simultaneously handle radial, axial, and moment loads due to their perpendicular roller arrangement. This multi-directional load-handling capability significantly reduces the need for additional bearing components, leading to more compact and efficient mechanical designs.

The precision aspect of cross roller bearings also sets them apart. The roller arrangement allows for more precise rotation control and minimal deviation, achieving accuracy levels of up to 0.001mm in some applications. This level of precision is particularly crucial in high-accuracy equipment such as semiconductor manufacturing machines, medical devices, and precision measuring instruments.

Furthermore, the design of cross roller bearings incorporates sophisticated cage structures that maintain proper roller spacing and orientation. These cages are engineered to minimize friction while ensuring optimal roller guidance, resulting in smoother operation and reduced heat generation compared to traditional bearings. The reduced friction not only enhances operational efficiency but also contributes to extended bearing life and reduced maintenance requirements.

How Do You Properly Maintain RB Cross Roller Bearings for Maximum Lifespan?

Proper maintenance of RB Cross Roller Bearings is crucial for ensuring optimal performance and maximizing their operational lifespan. A comprehensive maintenance strategy encompasses several key aspects, including proper lubrication, regular inspection, environmental protection, and appropriate handling procedures.

Lubrication plays a pivotal role in bearing maintenance. The correct type and amount of lubricant must be selected based on specific operating conditions, including speed, load, and temperature. High-quality synthetic greases or oils specifically formulated for precision bearings are typically recommended. The lubrication schedule should be carefully monitored and maintained, with regular relubrication intervals determined by operating conditions and manufacturer specifications.

Regular inspection procedures form another critical component of maintenance. Visual inspections should be conducted periodically to check for signs of wear, contamination, or damage. This includes examining the roller surfaces for any irregularities, checking the cage condition, and assessing the overall bearing alignment. Advanced monitoring techniques, such as vibration analysis and temperature monitoring, can provide early warning signs of potential issues before they develop into serious problems.

Environmental protection is equally important in bearing maintenance. Cross roller bearings should be protected from contamination, moisture, and excessive temperature variations. This may involve using appropriate sealing solutions, maintaining clean operating environments, and implementing proper storage procedures when bearings are not in use. In particularly demanding environments, specialized sealing arrangements or protective coatings may be necessary to ensure optimal bearing protection.

Handling and installation procedures significantly impact bearing performance and longevity. Proper installation techniques, including correct alignment and mounting procedures, are essential. Tools and equipment specifically designed for bearing installation should be used to avoid damage during assembly. Additionally, proper preload settings must be maintained to ensure optimal bearing performance and prevent premature wear.

Temperature control is another crucial aspect of maintenance. Monitoring and maintaining appropriate operating temperatures helps prevent thermal expansion issues and ensures proper lubrication effectiveness. Excessive temperatures can lead to lubricant breakdown and accelerated wear, while too low temperatures might affect lubricant viscosity and bearing performance.

Documentation and record-keeping of maintenance activities are essential for tracking bearing performance and predicting maintenance needs. This includes maintaining detailed records of lubrication schedules, inspection results, and any observed changes in bearing behavior or performance. Such documentation helps in developing more effective maintenance strategies and identifying potential problems before they become critical.

What Industries Most Commonly Use RB Cross Roller Bearings and Why?

RB Cross Roller Bearings find extensive application across various industries due to their unique capabilities and performance characteristics. Understanding the specific requirements and applications in different sectors helps illustrate why these bearings have become indispensable in modern industrial applications.

The robotics and automation industry represents one of the largest users of cross roller bearings. In robotic arms and automated manufacturing equipment, these bearings provide the precise movement control and multi-directional load handling capabilities essential for complex automated operations. Their compact design allows for sleeker robot joint designs while maintaining the necessary load-carrying capacity and precision. For instance, in six-axis industrial robots, cross roller bearings enable smooth, accurate movements while handling substantial payloads, contributing to improved manufacturing efficiency and precision.

Semiconductor manufacturing equipment represents another critical application area. The extreme precision requirements in semiconductor production make cross roller bearings ideal for various manufacturing stages. These bearings support the precise positioning systems required for wafer handling, inspection, and processing equipment. Their ability to maintain accuracy under varying loads and speeds, combined with low particle generation characteristics, makes them particularly suitable for cleanroom environments.

The medical equipment industry extensively utilizes cross roller bearings in various applications, from imaging equipment to surgical robots. In medical imaging devices such as CT scanners and MRI machines, these bearings support smooth, precise rotational movements while handling significant loads. Their reliability and precision are crucial for obtaining accurate diagnostic images and ensuring patient safety. In surgical robots and equipment, cross roller bearings enable precise control and movement necessary for delicate procedures.

Machine tool applications represent another significant use case. In precision machinery, such as CNC machines and measuring equipment, cross roller bearings provide the high accuracy and rigidity required for precise cutting and measurement operations. Their ability to handle combined loads while maintaining positioning accuracy makes them ideal for machine tool spindles and linear motion systems.

The aerospace industry utilizes cross roller bearings in various applications, from satellite positioning systems to aircraft control surfaces. The bearings' ability to operate reliably under extreme conditions, including high vacuum and temperature variations, makes them suitable for space applications. Their compact design and high load capacity are particularly valuable in applications where weight and space are critical considerations.

Optical and laser equipment manufacturers rely on cross roller bearings for precise positioning and movement control. In applications such as laser cutting machines, microscopes, and optical measurement devices, these bearings provide the smooth, accurate motion necessary for optimal performance. Their low friction characteristics and high positioning accuracy contribute to improved optical system performance and reliability.

At Luoyang Huigong Bearing Technology Co., Ltd., we understand the complexities of industrial bearing requirements. Our experienced R&D team provides technical guidance, customized solutions for different working conditions, and leverages 30 years of industry expertise through collaborations with major enterprises. With advanced production equipment and testing instruments, our company holds over 50 invention patents and has obtained ISO9001 quality management system and ISO14001 environmental management system certifications. As a 2024 quality benchmark enterprise, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. Journal of Mechanical Engineering Science, "Advanced Bearing Technologies in Modern Manufacturing" (2023)

2. NSK Technical Report, "Cross Roller Bearing Design and Applications" (2023)

3. International Journal of Precision Engineering, "Precision Bearing Systems in Industry 4.0" (2022)

4. SKF Bearing Handbook, "Industrial Bearing Selection and Maintenance" (2023)

5. Robotics and Automation Magazine, "Bearing Solutions for Industrial Robots" (2023)

6. Machine Design Journal, "Advances in Bearing Technology for Precision Applications" (2022)

7. Tribology International, "Lubrication and Wear in Cross Roller Bearings" (2023)

8. IHS Engineering360, "Cross Roller Bearing Selection Guide" (2023)

9. Bearing News, "Industrial Applications of Precision Bearings" (2023)

10. Manufacturing Technology Research, "Modern Bearing Solutions in Advanced Manufacturing" (2023)