How Does an Angular Contact Ball Bearing Work?

Angular contact ball bearings are sophisticated mechanical components that play a crucial role in modern machinery and equipment. These specialized bearings are designed to handle both radial and axial loads simultaneously, making them indispensable in applications where forces act in multiple directions. Unlike standard ball bearings, their unique design features raceways that are displaced relative to each other in the direction of the bearing axis, creating an optimal contact angle that enhances their load-bearing capabilities and operational efficiency. The fundamental principle behind their operation lies in the geometric arrangement of their components, which creates a specific load path that efficiently distributes forces through the bearing structure. This design allows for higher precision in rotational movements while maintaining stability under varying load conditions.

What Makes Angular Contact Ball Bearings Different from Other Bearing Types?

Angular contact ball bearings stand apart from other bearing types due to their distinctive design characteristics and operational principles. The primary differentiating factor lies in their internal geometry, specifically the contact angle between the balls and raceways. This angle, typically ranging from 15 to 40 degrees, enables the bearing to handle combined loads more effectively than conventional bearings. The raceway orientation creates an asymmetrical load path through the balls, allowing for superior thrust load capacity in one direction.

The bearing's design incorporates precisely engineered raceways on both inner and outer rings, with one shoulder higher than the other. This asymmetrical configuration creates a contact angle that determines the bearing's load-carrying capabilities. The steeper the contact angle, the greater the axial load capacity, though this comes with a corresponding reduction in radial load capacity. This unique design also affects the bearing's speed capabilities, with higher contact angles generally resulting in lower maximum rotational speeds.

Another distinguishing feature is their separable design, where the inner ring, ball set, and outer ring can be mounted separately. This characteristic makes them particularly suitable for applications requiring precise preload adjustments or where differential thermal expansion between shaft and housing must be accommodated. The separability also facilitates easier maintenance and installation, especially in machinery where access is limited or where specific mounting arrangements are required.

The material composition and manufacturing precision of angular contact ball bearings also set them apart. High-grade steel alloys are typically used, with surfaces ground and honed to extremely tight tolerances. The balls themselves are manufactured to exceptional roundness specifications, often deviating by less than a few millionths of an inch from perfect sphericity. This precision is crucial for maintaining accurate shaft positioning and ensuring smooth operation under high-speed conditions.

How Are Angular Contact Ball Bearings Installed and Maintained Properly?

The installation and maintenance of angular contact ball bearings require careful attention to detail and adherence to specific procedures to ensure optimal performance and longevity. The installation process begins with thorough cleaning of all components and careful inspection of mounting surfaces. Proper alignment is crucial, as misalignment can significantly reduce bearing life and performance. The mounting surfaces must be machined to appropriate tolerances, and surrounding components must be designed to provide adequate support and proper load distribution.

During installation, special attention must be paid to the preload setting, which is critical for optimal bearing performance. Preload can be achieved through various methods, including spring preload, fixed preload, or adjustable preload systems. The chosen method depends on the application requirements and operating conditions. Temperature considerations are also essential, as thermal expansion can affect preload and operating clearances. Proper lubrication is crucial during installation, with the type and amount of lubricant carefully selected based on operating conditions, speed, and load requirements.

Maintenance procedures include regular monitoring of bearing temperature, vibration levels, and lubrication condition. Periodic relubrication schedules should be established based on operating conditions and manufacturer recommendations. Contamination control is critical, and proper sealing arrangements must be maintained to prevent the ingress of harmful particles or moisture. Regular inspection of bearing condition through various monitoring techniques, such as vibration analysis or temperature monitoring, can help detect potential issues before they lead to failure.

Advanced maintenance practices often incorporate condition monitoring systems that can provide real-time data on bearing performance. These systems may include sensors for temperature measurement, vibration analysis equipment, and oil analysis programs. The data collected can be used to predict potential failures and schedule maintenance activities proactively, reducing unexpected downtime and extending bearing life.

What Are the Common Applications and Load Considerations for Angular Contact Ball Bearings?

Angular contact ball bearings find extensive applications across various industries due to their versatility in handling combined loads. In machine tool applications, they are commonly used in spindle arrangements where high precision and stability are required under varying load conditions. The automotive industry utilizes these bearings in wheel hub assemblies, where they must handle both radial loads from vehicle weight and axial loads during cornering.

The aerospace industry relies heavily on angular contact ball bearings in aircraft engines, where they support high-speed rotating components under extreme conditions. In these applications, the bearings must maintain precision while handling significant thermal variations and high dynamic loads. Industrial pumps and compressors also benefit from these bearings, particularly in arrangements where shaft positioning accuracy is crucial for maintaining proper clearances and ensuring efficient operation.

Load considerations for these bearings are complex and must account for multiple factors. The ratio of axial to radial loads affects bearing selection and arrangement design. Operating speed is a critical factor, as it influences lubrication requirements and heat generation. Environmental conditions, including temperature extremes and exposure to contamination, must be considered in the selection process. The required service life and reliability levels also influence bearing selection and arrangement design.

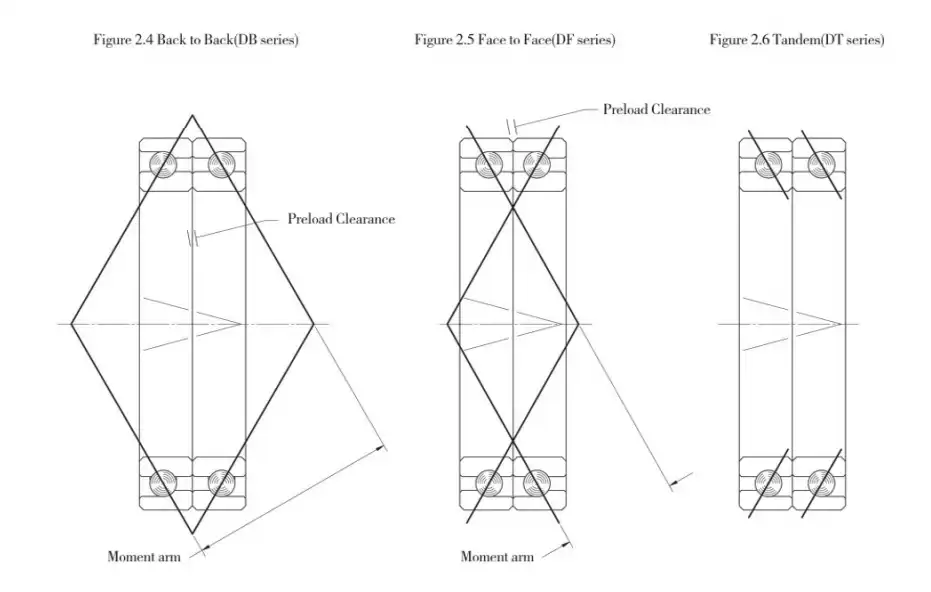

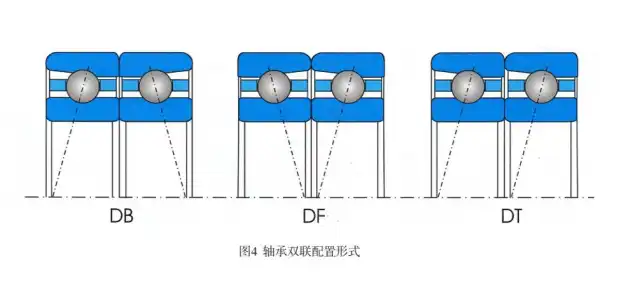

Dynamic load ratings must be carefully evaluated, considering both the magnitude and direction of applied loads throughout the operating cycle. Moment loads, which can arise from shaft misalignment or unbalanced forces, must also be considered in the design phase. The selection of appropriate bearing arrangements, whether single, duplex, or multiple bearing sets, depends on these load considerations and application requirements.

In high-precision applications, such as machine tool spindles, Angular Contact Ball Bearing arrangement design must consider not only load capacity but also stiffness requirements and thermal behavior. The use of ceramic balls in hybrid bearings has become increasingly common in these applications, offering benefits such as reduced thermal expansion, lower friction, and higher speed capabilities. The selection of cage designs also plays a crucial role in high-speed applications, with options ranging from traditional pressed steel cages to advanced polymer designs optimized for specific operating conditions.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. SKF Group. (2023). "Angular Contact Ball Bearings: Technical Principles and Design." SKF Bearing Technology Handbook.

2. NSK Americas. (2024). "Application and Selection Guide for Angular Contact Ball Bearings." NSK Technical Report Series.

3. Timken Company. (2023). "Engineering Manual: Angular Contact Ball Bearing Design and Selection." Timken Technical Publications.

4. JTEKT Corporation. (2023). "Koyo Angular Contact Ball Bearings Catalog." Koyo Technical Documentation.

5. NTN Corporation. (2024). "NTN Technical Review: Advances in Angular Contact Ball Bearing Technology." NTN Engineering Journal.

6. FAG Schaeffler. (2023). "Understanding Angular Contact Ball Bearings." Schaeffler Technical Guide.

7. INA Bearing Company. (2024). "Installation and Maintenance Guide for Precision Bearings." INA Technical Bulletin.

8. THK Co., Ltd. (2023). "Linear Motion Systems and Angular Contact Technology." THK Technical Review.

9. Machine Design Magazine. (2024). "Bearing Selection and Application Guide." Engineering Resources Series.

10. American Bearing Manufacturers Association. (2023). "ABMA Standards for Angular Contact Ball Bearings." Technical Standards Publication.