What Materials are Typically Used in Type A thin Section Bearings?

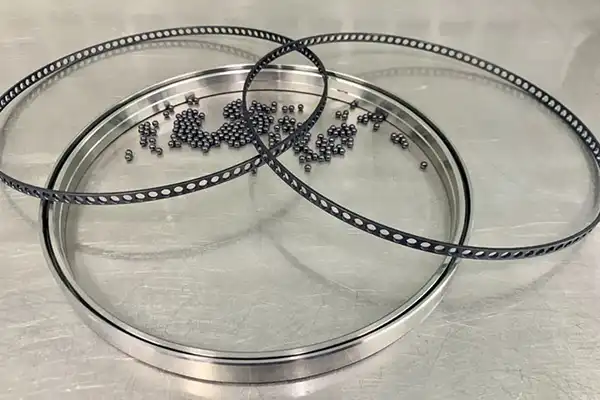

Type A thin section bearings are precision engineering components that represent a remarkable advancement in bearing technology. These specialized bearings are characterized by their distinctive cross-section design, which maintains a constant ring thickness ratio while offering exceptional performance in applications where space is at a premium. The materials used in their construction play a crucial role in determining their performance, durability, and application suitability.

The primary materials used in Type A thin section bearings are carefully selected high-grade bearing steels, typically including AISI 52100 chrome steel for rings and rolling elements. These materials undergo extensive metallurgical processing to achieve optimal hardness, wear resistance, and dimensional stability. Advanced material technologies have introduced alternatives such as stainless steel variants (like 440C) for corrosive environments and hybrid designs incorporating ceramic rolling elements for high-speed applications.

The cage materials are equally important, with options ranging from machined brass and polyamide to advanced engineered polymers like PEEK (Polyether Ether Ketone). Each material choice offers specific advantages - brass provides excellent strength and thermal conductivity, while polymer cages offer reduced weight and improved lubricant retention characteristics.

How do Type A thin section bearings differ from standard bearings?

Type A thin section bearings represent a significant departure from conventional bearing designs, primarily due to their unique dimensional characteristics and construction methodology. These bearings maintain a constant cross-section throughout their diameter range, which is a stark contrast to standard bearings that typically increase in cross-sectional thickness as their diameter grows. The fundamental difference lies in their section height to bearing diameter ratio, which remains remarkably small compared to conventional bearings.

The construction of Type A thin section bearings involves precision engineering techniques that allow for the maintenance of tight tolerances despite their thin-walled design. The rings are manufactured with exceptional attention to dimensional accuracy, typically maintaining roundness tolerances within micrometers. This precision is achieved through advanced manufacturing processes, including specialized heat treatment methods that prevent distortion of the thin sections during hardening.

The geometry of Type A thin section bearings presents unique challenges in manufacturing. Unlike standard bearings, which often have more forgiving tolerances, these bearings require extremely precise control of raceway geometry and surface finish. The thin walls make them particularly susceptible to distortion during heat treatment, necessitating specialized processes that maintain dimensional stability while achieving the required material properties.

One of the most distinctive features is their weight-to-load capacity ratio. Due to their optimized design, Type A thin section bearings can handle significant loads while maintaining a fraction of the weight of standard bearings. This characteristic makes them particularly valuable in applications where weight reduction is crucial, such as aerospace equipment, medical devices, and robotic systems.

The mounting and installation procedures also differ significantly. Type A thin section bearings require more precise mounting surfaces and careful handling during installation due to their thin-walled construction. Special mounting procedures are often necessary to prevent distortion and ensure optimal performance, unlike standard bearings which are generally more forgiving during installation.

The internal geometry of Type A thin section bearings is optimized differently from standard bearings. The contact angles, raceway curvatures, and internal clearances are carefully designed to accommodate the unique characteristics of thin-walled rings. This optimization ensures proper load distribution and minimizes stress concentrations that could lead to premature failure.

What are the ideal operating conditions for Type A thin section bearings?

The optimal performance of Type A thin section bearings is heavily dependent on maintaining appropriate operating conditions. These bearings excel in environments where traditional bearings might be impractical or inefficient, but they require specific conditions to achieve their full potential.

Temperature considerations play a vital role in their operation. The ideal operating temperature range typically falls between -20°C to +120°C for standard materials, though this can be extended with specialized materials and lubricants. Temperature stability is crucial as rapid fluctuations can affect the bearing's dimensional stability due to their thin-walled construction.

The thermal management of Type A thin section bearings requires careful consideration of heat generation and dissipation. Due to their minimal cross-section, these bearings have limited thermal mass and heat dissipation capability compared to standard bearings. This characteristic necessitates careful monitoring of operating temperatures and may require additional cooling measures in high-speed applications.

Speed capabilities are another critical factor. Type A thin section bearings can operate at relatively high speeds, but they require proper lubrication and cooling to maintain optimal performance. The speed limits are often determined by the bearing size, load conditions, and lubrication method. For precision applications, speed ratings may need to be reduced to maintain accuracy and minimize heat generation.

Load capacity considerations are particularly important. While these bearings can handle significant loads relative to their size, they perform best under moderate loads with proper load distribution. Axial and radial loads should be carefully calculated and monitored to prevent excessive stress on the thin sections. The bearing's mounting arrangement significantly influences its load-carrying capacity, with proper support being essential for optimal performance.

Environmental conditions also play a crucial role. These bearings perform best in clean, controlled environments where contamination can be minimized. In applications where exposure to harsh conditions is unavoidable, special sealing arrangements and protective measures may be necessary to ensure reliable operation.

The selection of appropriate lubrication systems is critical for optimal performance. Oil lubrication systems must be carefully designed to ensure proper oil film formation without excessive churning losses. Grease lubrication requires special consideration of base oil viscosity and thickener type to achieve adequate lubricant film thickness while maintaining low friction characteristics.

What innovations have improved Type A thin section bearing performance?

Recent technological advancements have significantly enhanced the capabilities and reliability of Type A thin section bearings. Material science developments have led to the introduction of new steel compositions and surface treatments that extend bearing life and improve performance under challenging conditions.

Advanced coating technologies have revolutionized the surface properties of these bearings. Modern coatings can provide enhanced wear resistance, improved lubrication retention, and better protection against corrosion. Thin-film coatings, such as diamond-like carbon (DLC) and titanium nitride, have become increasingly common in high-performance applications.

The development of hybrid bearings, incorporating ceramic rolling elements with steel rings, has opened new possibilities for high-speed and high-temperature applications. These designs benefit from the lower density and higher hardness of ceramic materials, resulting in reduced centrifugal forces and improved wear resistance.

Manufacturing processes have also evolved significantly. The implementation of precision grinding techniques and advanced heat treatment methods has improved dimensional accuracy and material properties. Computer-controlled manufacturing processes ensure consistent quality and allow for tighter tolerances than ever before.

The integration of sensor technology has enabled smart bearing solutions that can monitor their own operating conditions. Embedded sensors can track parameters such as temperature, speed, and vibration, providing real-time feedback for predictive maintenance and optimal operation.

Cage design innovations have contributed to improved bearing performance. Modern cage materials and designs enhance lubricant distribution and reduce friction, leading to cooler operating temperatures and extended bearing life. Polymer cages, in particular, have gained popularity due to their lightweight properties and excellent wear characteristics.

Lubrication technology has also seen significant advancement. New lubricant formulations specifically designed for thin section bearings provide better protection and longer service life. The development of solid lubricant systems and specialized greases has expanded the application range of these bearings into more demanding environments.

Computational modeling and simulation tools have revolutionized the design process for Type A thin section bearings. Advanced finite element analysis and multiphysics simulation capabilities enable engineers to optimize bearing designs for specific applications, predicting performance under various operating conditions before physical prototypes are manufactured.

The implementation of Industry 4.0 principles has led to improved quality control and traceability in bearing manufacturing. Digital twin technology allows for continuous monitoring and optimization of bearing performance throughout their lifecycle, while automated inspection systems ensure consistent quality and early detection of potential defects.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. Journal of Tribology, "Advanced Materials in Modern Bearing Design" (2023)

2. International Journal of Mechanical Engineering, "Thin Section Bearing Technology" (2022)

3. SKF Technical Report, "Innovations in Bearing Materials and Coatings" (2023)

4. NSK Engineering Report, "Thin Section Bearing Applications Guide" (2022)

5. Timken Company Research Publication, "Material Selection for Precision Bearings" (2023)

6. ASME Journal of Engineering, "Modern Bearing Manufacturing Processes" (2022)

7. Bearing News Magazine, "Advances in Thin Section Bearing Technology" (2023)

8. Materials Science and Engineering Journal, "Surface Engineering for Bearing Applications" (2022)

9. Tribology International, "Lubrication Systems for Precision Bearings" (2023)

10. Journal of Mechanical Design, "Optimization of Thin Section Bearing Design" (2022)