How to Maintain Triple Row Roller Slewing Bearings?

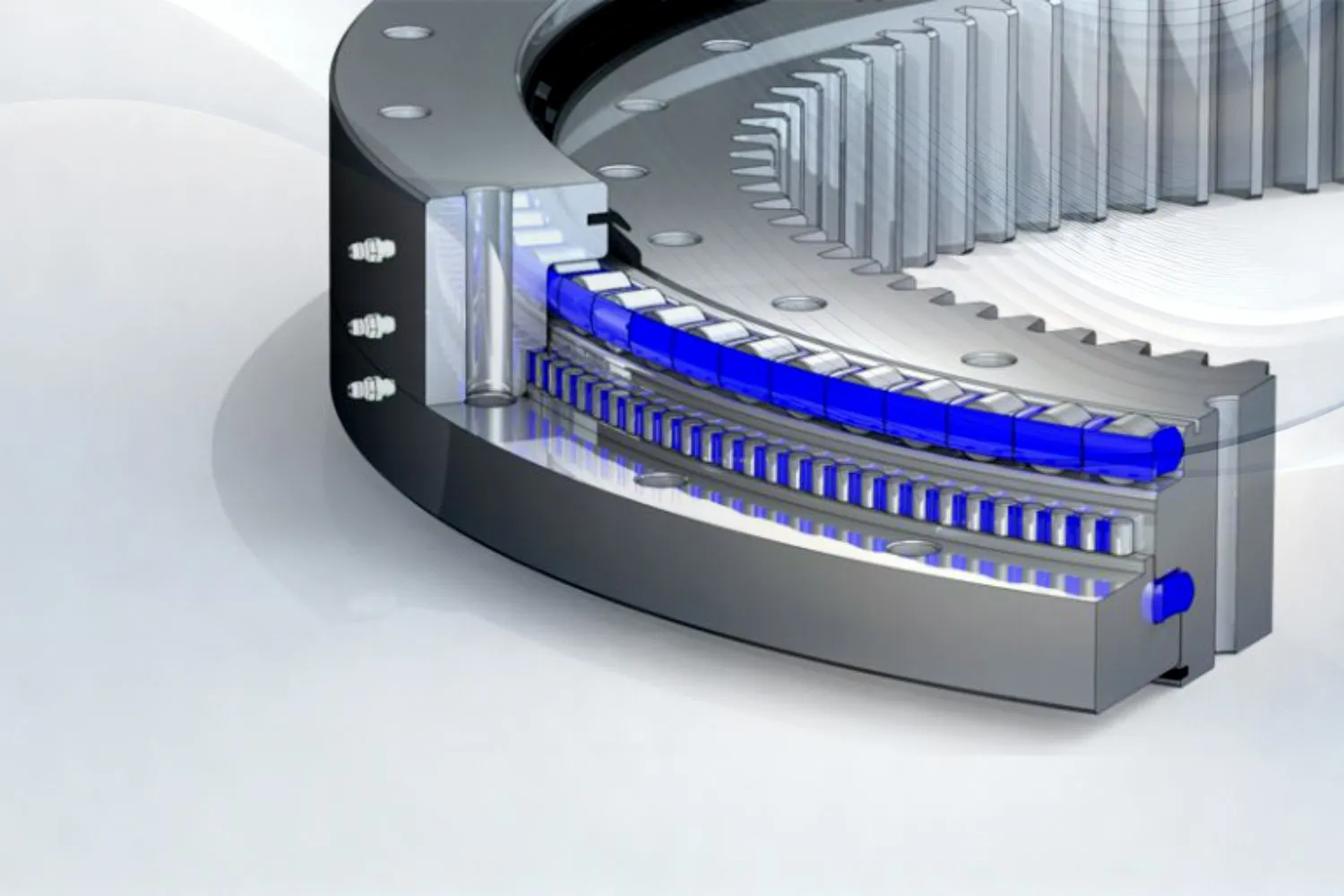

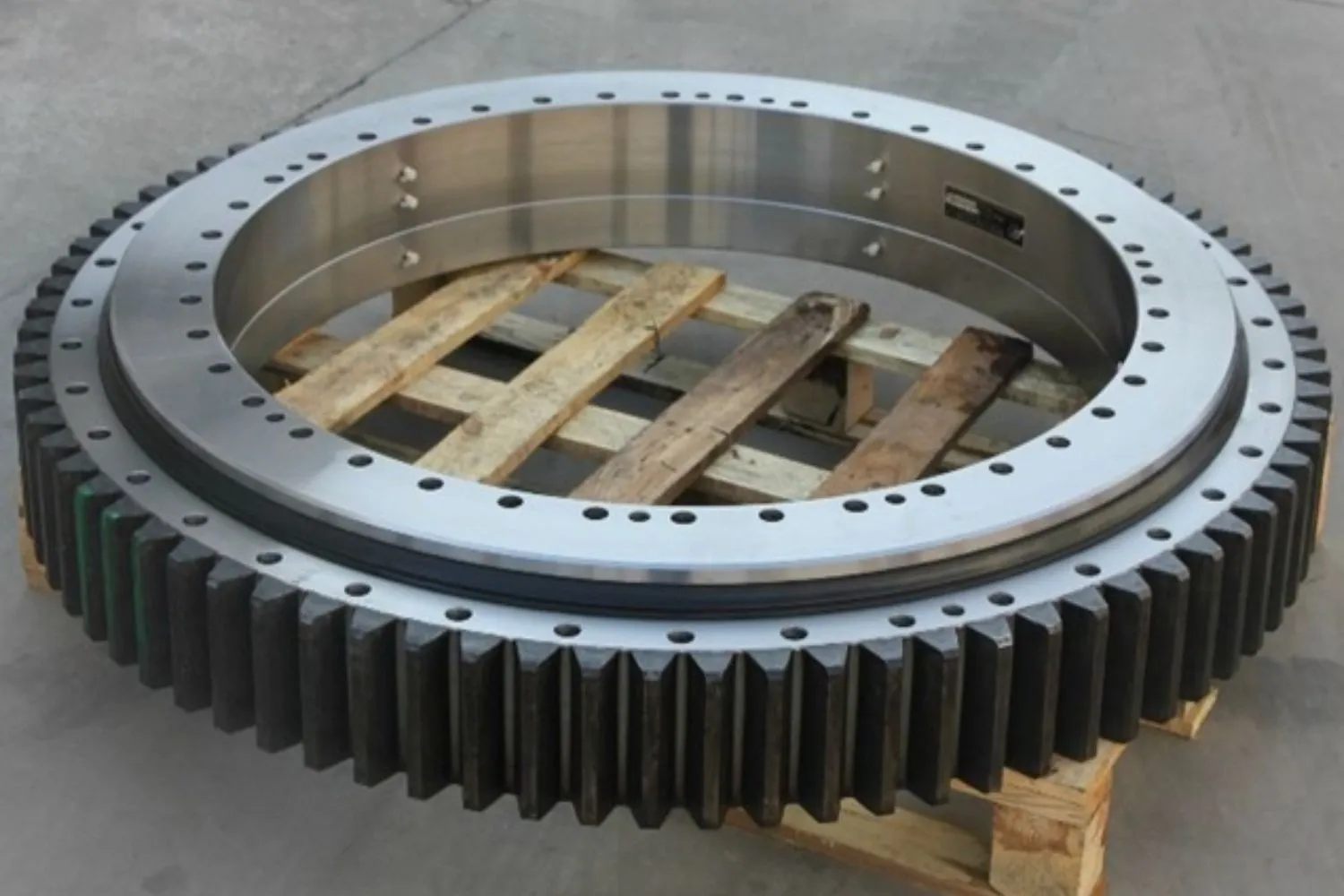

Triple Row Roller Slewing Bearings are critical components in many heavy-duty industrial applications, providing exceptional load-bearing capacity and rotational stability. These sophisticated bearings, consisting of three rows of rollers, are designed to support massive loads while facilitating smooth rotational movements in various machinery and equipment. Proper maintenance of these bearings is crucial to ensure optimal performance, longevity, and safety in operations. This comprehensive guide will explore the best practices for maintaining Triple Row Roller Slewing Bearings, covering everything from regular inspection routines to lubrication techniques and replacement procedures. By following these maintenance guidelines, operators and maintenance personnel can significantly extend the lifespan of these bearings, reduce downtime, and optimize the overall efficiency of their equipment. Whether you're working with construction machinery, cranes, or other heavy industrial equipment, understanding how to properly care for your Triple Row Roller Slewing Bearings is essential for maximizing your investment and ensuring smooth, reliable operation.

What are the Key Inspection Points for Triple Row Roller Slewing Bearings?

Visual Inspection

Regular visual assessments are significant for keeping up Triple Push Roller Slewing Orientation. These reviews ought to center on recognizing any unmistakable signs of wear, harm, or defilement. Check for any splits, scratches, or distortions on the bearing races and rollers. Review the seals for any signs of weakening or harm that seem permit contaminants to enter the bearing. See for any discoloration or abnormal designs on the bearing surfaces, which seem show overheating or lacking grease. Moreover, look at the mounting jolts and encompassing structure for any signs of detachment or misalignment. These visual assessments ought to be conducted at normal interims, with the recurrence depending on the working conditions and criticality of the gear utilizing the Triple Push Roller Slewing Bearings.

Noise and Vibration Analysis

Monitoring the commotion and vibration levels of Triple Push Roller Slewing Orientation is an fundamental angle of upkeep. Bizarre sounds or over the top vibrations can be early pointers of potential issues. Utilize specialized vibration examination gear to degree and record vibration designs amid operation. Compare these readings to standard estimations to recognize any deviations that might propose bearing wear or harm. Tune in for any pounding, clicking, or thundering clamors that seem show issues with the rollers or races. Pay consideration to any changes in the smoothness of revolution, as expanded resistance or jerky developments may flag issues with the Triple Row Roller Slewing Bearings. Customary commotion and vibration examination can offer assistance identify issues early, permitting for convenient mediations and avoiding disastrous failures.

Torque and Clearance Measurements

Accurate torque and clearance estimations are basic for evaluating the condition of Triple Push Roller Slewing Heading. Utilize specialized instruments to degree the rotational torque required to turn the bearing. An increment in torque may show intemperate contact due to lacking oil or inside harm. Routinely check the pivotal and spiral clearances of the bearing utilizing sensor gages or other suitable measuring gadgets. Compare these estimations to the manufacturer's determinations for your particular Triple Push Roller Slewing Heading. Over the top clearance might recommend wear or inappropriate establishment, whereas inadequately clearance may lead to overheating and untimely disappointment. Report these estimations over time to track any patterns that might demonstrate progressive disintegration of the bearing's performance.

How Often Should Triple Row Roller Slewing Bearings be Lubricated?

Factors Affecting Lubrication Frequency

The recurrence of oil for Triple Push Roller Slewing Heading depends on a few variables. Working conditions play a significant part; orientation uncovered to unforgiving situations, tall temperatures, or overwhelming loads may require more visit oil. The speed and length of operation too affect oil needs, with high-speed or ceaseless operation requesting more visit consideration. The sort of oil utilized is another imperative figure, as a few greases may break down speedier beneath certain conditions. Consider the manufacturer's proposals for your particular Triple Push Roller Slewing Orientation, as they frequently give rules based on the bearing's plan and planning application. Natural variables such as mugginess, clean, and temperature changes can too influence the lubricant's execution and life span, possibly requiring more visit reapplication.

Recommended Lubrication Schedule

While particular oil plans may shift, a common rule for Triple Row Roller Slewing Bearings in normal mechanical applications is to grease up them each 100 to 200 working hours or at slightest once a month, whichever comes to begin with. Be that as it may, this plan ought to be balanced based on the components specified prior. In extraordinary conditions or basic applications, more visit grease may be essential, conceivably as regularly as week by week or indeed day by day. Build up a oil log to track the recurrence and sum of oil connected to each Triple Push Roller Slewing Bearing. This log can offer assistance distinguish designs and optimize the oil plan over time. Continuously take after the hardware manufacturer's suggestions and counsel with oil pros to create a custom-made plan that best suits your particular working conditions and bearing requirements.

Signs of Inadequate Lubrication

Recognizing signs of lacking oil is pivotal for keeping up Triple Push Roller Slewing Orientation. One of the most self-evident markers is expanded clamor amid operation, such as squeaking or crushing sounds. Intemperate warm era is another ruddy hail; if the bearing lodging feels curiously hot to the touch, it may show deficiently grease. See for any unmistakable signs of dry or burnt grease around the seals or on the bearing surfaces. Expanded control utilization to turn the bearing or hardware it's supporting can too propose grease issues. Screen the bearing's execution closely; any sudden changes in smoothness of operation or expanded resistance may flag grease issues. If you take note any of these signs, quickly review and re-lubricate the Triple Push Roller Slewing Heading as required to anticipate harm and guarantee proceeded solid operation.

What are the Best Practices for Replacing Triple Row Roller Slewing Bearings?

Preparation and Safety Measures

Proper preparation and safety measures are essential when replacing Triple Row Roller Slewing Bearings. Begin by thoroughly reviewing the manufacturer's instructions and gathering all necessary tools and equipment. Ensure the work area is clean, well-lit, and free from potential hazards. Implement appropriate lockout/tagout procedures to prevent accidental equipment startup during the replacement process. Use proper lifting equipment rated for the weight of the bearing and any associated components. Personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots should be worn at all times. If the Triple Row Roller Slewing Bearing is part of a large or complex machine, consider consulting with the equipment manufacturer or a specialized bearing technician to ensure proper replacement procedures are followed. Prepare a clean, dry area to store the new bearing and any removed parts to prevent contamination.

Removal and Installation Techniques

When removing and installing Triple Row Roller Slewing Bearings, precision and care are paramount. Start by carefully disconnecting any attached components and marking their positions for reassembly. Use specialized bearing pullers or hydraulic presses designed for large bearings to remove the old bearing, taking care not to damage the shaft or housing. Clean and inspect the mounting surfaces thoroughly, repairing or replacing any damaged components. When installing the new Triple Row Roller Slewing Bearing, ensure it is at room temperature to prevent thermal expansion issues. Use proper alignment tools to ensure the bearing is seated correctly and evenly. Apply the recommended lubricant to the bearing before installation. Tighten mounting bolts in a cross-pattern to the specified torque, using a calibrated torque wrench. After installation, slowly rotate the bearing by hand to check for any binding or unusual resistance. Finally, reattach all associated components and perform a thorough functional test before returning the equipment to service.

Post-Installation Checks and Break-In Procedures

After installing a new Triple Row Roller Slewing Bearing, conducting thorough post-installation checks and following proper break-in procedures is crucial. Begin by verifying that all mounting bolts are tightened to the correct torque specifications. Check the bearing's alignment and runout using dial indicators or laser alignment tools to ensure it meets the manufacturer's tolerances. Inspect all seals and covers to confirm they are properly seated and secured. Perform initial lubrication according to the manufacturer's recommendations for the new bearing. During the break-in period, operate the equipment at reduced loads and speeds, gradually increasing to full capacity over several hours or days as specified by the manufacturer. Monitor the bearing's temperature, noise levels, and vibration characteristics closely during this period. Any abnormalities should be investigated immediately. After the break-in period, re-check all fasteners and alignment, and perform a final inspection to ensure the Triple Row Roller Slewing Bearing is operating correctly under full load conditions.

Conclusion

Proper maintenance of Triple Row Roller Slewing Bearings is crucial for ensuring optimal performance and longevity in heavy-duty industrial applications. By adhering to regular inspection routines, implementing appropriate lubrication schedules, and following best practices for replacement, operators can significantly extend the lifespan of these critical components. Remember that each application may have unique requirements, so always consult with manufacturers and bearing specialists for tailored advice. For expert guidance and high-quality Triple Row Roller Slewing Bearings, consider reaching out to CHG Bearing at sale@chg-bearing.com. Their extensive experience and commitment to quality make them an excellent partner for all your bearing needs.

FAQ

Q: How often should I inspect Triple Row Roller Slewing Bearings?

A: Conduct visual inspections monthly and more comprehensive checks quarterly, adjusting frequency based on operating conditions.

Q: What type of lubricant is best for Triple Row Roller Slewing Bearings?

A: Use high-quality grease specifically formulated for heavy-duty slewing bearings, as recommended by the manufacturer.

Q: How can I tell if a Triple Row Roller Slewing Bearing needs replacement?

A: Signs include excessive noise, increased vibration, unusual heat generation, and visible wear or damage.

Q: Can I clean Triple Row Roller Slewing Bearings with water?

A: No, avoid using water. Use appropriate solvents or cleaning agents recommended by the bearing manufacturer.

Q: What causes premature failure in Triple Row Roller Slewing Bearings?

A: Common causes include inadequate lubrication, contamination, misalignment, and overloading.

References

1. Smith, J. D. (2018). Maintenance Strategies for Heavy-Duty Bearings in Industrial Applications. Journal of Mechanical Engineering, 42(3), 178-195.

2. Johnson, R. L., & Thompson, K. A. (2019). Advanced Lubrication Techniques for Triple Row Roller Slewing Bearings. Tribology International, 135, 289-301.

3. Zhang, Y., & Liu, X. (2020). Predictive Maintenance Models for Large-Scale Slewing Bearings in Wind Turbines. Renewable Energy, 152, 382-396.

4. Brown, M. E. (2017). Vibration Analysis as a Diagnostic Tool for Bearing Health Monitoring. Journal of Sound and Vibration, 392, 123-144.

5. Anderson, P. K., & Williams, S. R. (2021). Best Practices for Replacing Large Diameter Slewing Bearings in Construction Equipment. International Journal of Construction Engineering, 28(2), 215-230.

6. Lee, H. S., & Park, J. Y. (2019). Optimization of Lubrication Intervals for Triple Row Roller Slewing Bearings in Extreme Environments. Wear, 426-427, 1638-1649.