Tower Crane Slewing Bearing Sealing and Protection Systems

Tower crane slewing bearing sealing and protection systems play a crucial role in ensuring the optimal performance and longevity of these essential components in construction and industrial operations. These systems are designed to safeguard the slewing bearings from environmental contaminants, moisture, and wear, thereby maintaining their efficiency and reliability. The sealing mechanisms prevent the ingress of dust, debris, and water, while the protection systems shield the bearings from impact and excessive stress. Together, these elements contribute to the smooth rotation of the crane, enhanced load-bearing capacity, and reduced maintenance requirements. As tower cranes continue to evolve in size and capability, the importance of advanced sealing and protection systems for their slewing bearings becomes increasingly paramount, driving innovation in materials, design, and implementation techniques.

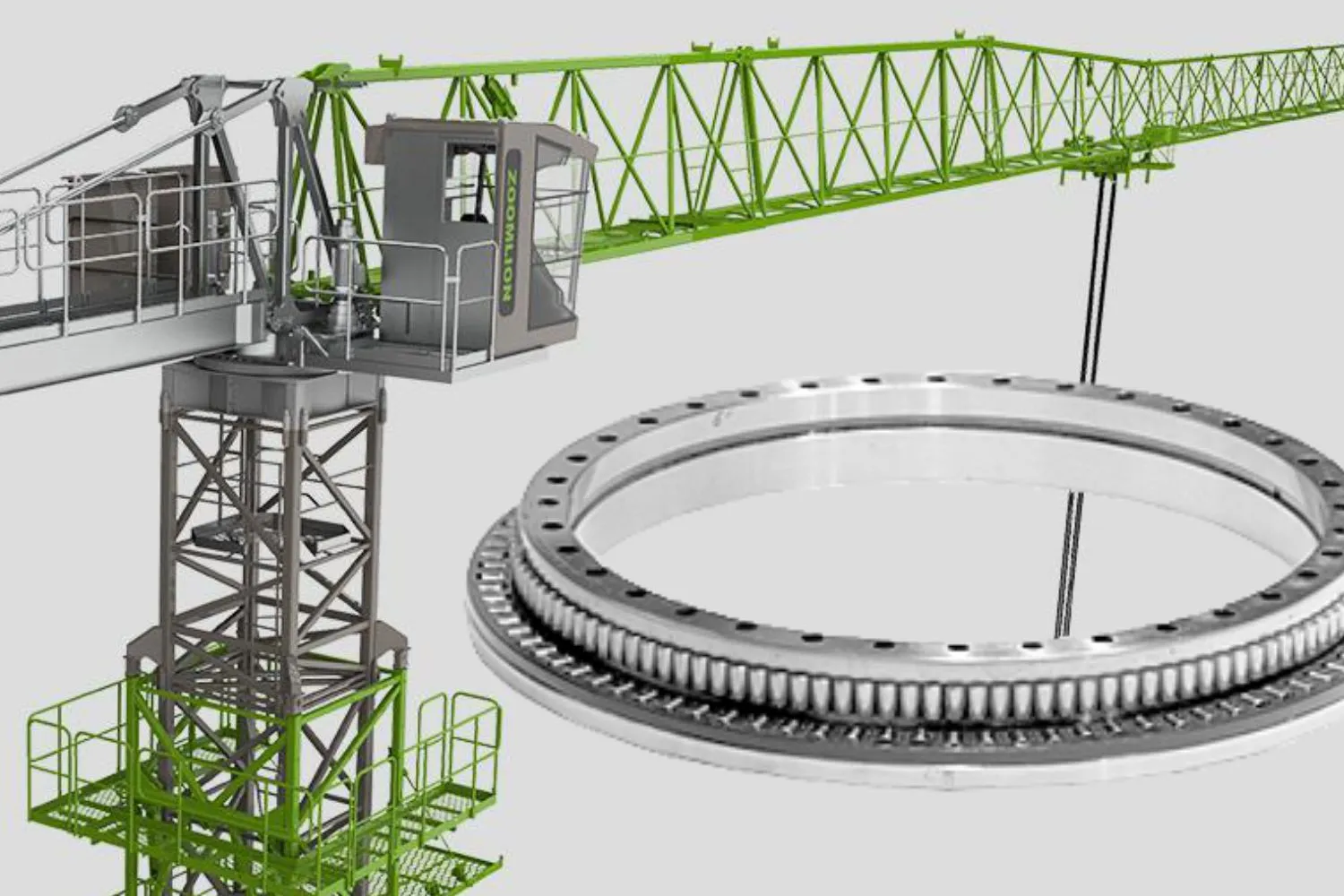

What are the key components of a Tower Crane Slewing Bearing?

Raceway and Rolling Elements

The raceway and rolling components are principal components of a Tower Crane Slewing Bearing. The raceway comprises of internal and external rings with absolutely machined surfaces that give a smooth way for the rolling components. These components, regularly balls or rollers, encourage the rotational development of the bearing beneath overwhelming loads. In Tower Crane applications, the plan of these components is pivotal as they must withstand colossal stresses whereas keeping up exactness. The fabric determination for both the raceway and rolling components is basic, with high-grade steel amalgams regularly utilized to guarantee strength and resistance to wear. The setup of these components specifically impacts the bearing's load-carrying capacity, rotational precision, and in general execution of the Tower Crane.

Sealing System

The fixing framework is a imperative portion of the Tower Crane Slewing Bearing, planned to ensure the inside components from natural contaminants and hold greases. This framework regularly incorporates numerous layers of seals, such as lip seals, maze seals, and some of the time indeed assistant seals for extraordinary conditions. The essential work is to avoid the entrance of tidy, water, and other particles that seem compromise the bearing's execution. For Tower Crane applications, where introduction to unforgiving climate and development flotsam and jetsam is common, the fixing framework must be especially vigorous. Progressed materials like high-performance polymers are regularly utilized to guarantee long-lasting viability. The plan of the fixing framework moreover considers the require for negligible contact to keep up the bearing's proficiency whereas giving most extreme protection.

Gear System

Many Tower Crane Slewing Heading consolidate an coordinates adapt framework, which is significant for the exact control of the crane's rotational development. This equip framework ordinarily comprises of an inside or outside adapt ring that networks with the crane's slewing drive instrument. The equip teeth are precision-machined to guarantee smooth engagement and negligible backfire, contributing to the exactness of the crane's situating. In Tower Crane applications, the equip framework must be planned to handle tall torque loads and stand up to wear over expanded periods of operation. The fabric and warm treatment of the equip teeth are carefully chosen to give ideal quality and toughness. Moreover, the integration of the equip framework with the bearing structure permits for a compact plan, decreasing the generally estimate and weight of the slewing mechanism.

How does the sealing system protect the Tower Crane Slewing Bearing?

Barrier Against Contaminants

The fixing framework of a Tower Crane Slewing Bearing acts as a impressive boundary against contaminants, playing a significant part in keeping up the bearing's execution and life span. This framework utilizes different layers of defense, ordinarily counting essential and auxiliary seals. The essential seal, frequently a lip seal or maze seal, gives the to begin with line of defense against bigger particles and dampness. It is planned to avoid the lion's share of contaminants some time recently they can reach the bearing's inside components. The auxiliary seal, which may be a cassette-type or extra lip seal, offers an additional layer of security, catching any better particles that might have passed the essential seal. In Tower Crane applications, where the bearing is uncovered to a assortment of natural challenges, counting tidy, rain, and in some cases indeed saltwater shower in coastal zones, this multi-layered approach is basic for guaranteeing the bearing's unwavering quality and efficiency.

Lubrication Retention

Another basic work of the fixing framework in Tower Crane Slewing Heading is the maintenance of oils. Appropriate oil is fundamental for diminishing grinding between the bearing's components, disseminating warm, and avoiding wear. The fixing framework is planned not as it were to keep contaminants out but too to keep oils in. This is especially vital in Tower Crane applications where the bearing works beneath tall loads and frequently in challenging natural conditions. The seals are built to make a tight boundary that avoids oil spillage, indeed when the bearing is subjected to different strengths and temperature changes. A few progressed fixing frameworks join extraordinary materials or plans that permit for controlled grease stream, guaranteeing that all basic surfaces stay satisfactorily greased up without intemperate misfortune of grease. This oil maintenance capability essentially expands the benefit interims of the Tower Crane Slewing Bearing and contributes to its by and large unwavering quality and performance.

Environmental Adaptation

The fixing framework of Tower Crane Slewing Heading is outlined with natural adjustment in intellect, permitting it to keep up its defensive properties over a wide run of working conditions. This flexibility is significant given the assorted situations in which tower cranes work, from bone-dry forsake conditions to sticky tropical climates. The seals are frequently made from materials that can withstand extraordinary temperatures, stand up to chemical corruption, and keep up their versatility over time. In a few progressed plans, the fixing framework may join keen highlights that react to changes in natural conditions. For case, a few seals may grow marginally in hot conditions to keep up a tight seal, or join waste channels to remove water in damp conditions. This natural adjustment guarantees that the Tower Crane Slewing Bearing remains secured notwithstanding of the challenging conditions it may confront, contributing to the crane's unwavering quality and decreasing the require for visit upkeep or substitutions due to natural harm.

What are the latest innovations in Tower Crane Slewing Bearing protection?

Smart Monitoring Systems

One of the most significant innovations in Tower Crane Slewing Bearing protection is the integration of smart monitoring systems. These advanced systems utilize sensors embedded within the bearing to continuously monitor various parameters such as temperature, vibration, and load distribution. The data collected is then processed in real-time, providing valuable insights into the bearing's performance and health. For Tower Crane applications, this technology allows operators to detect potential issues before they escalate into major problems, enabling predictive maintenance strategies. Some systems even incorporate machine learning algorithms that can predict bearing failures based on patterns in the data, further enhancing the reliability of the crane. These smart monitoring systems not only improve safety but also optimize maintenance schedules, reducing downtime and extending the overall lifespan of the Tower Crane Slewing Bearing.

Advanced Material Science

Recent advancements in material science have led to significant improvements in Tower Crane Slewing Bearing protection. Researchers and engineers are developing new alloys and composite materials that offer superior strength, wear resistance, and corrosion protection compared to traditional materials. For instance, some bearings now incorporate ceramic rolling elements that provide better performance under high loads and temperatures. Nano-engineered coatings are being applied to bearing surfaces, enhancing their hardness and reducing friction. In the realm of sealing systems, new polymer blends are being introduced that offer improved resistance to environmental factors while maintaining flexibility and sealing properties. These advanced materials contribute to the overall durability and efficiency of Tower Crane Slewing Bearings, allowing them to withstand more challenging operating conditions and heavier loads, ultimately improving the performance and reliability of tower cranes in various applications.

Enhanced Lubrication Technologies

Innovative lubrication technologies are revolutionizing the protection of Tower Crane Slewing Bearings. Traditional grease-based lubrication systems are being supplemented or replaced by more advanced solutions. One such innovation is the development of self-lubricating bearings that incorporate solid lubricants into the bearing material itself, reducing the need for external lubrication and minimizing maintenance requirements. Another advancement is the use of automated lubrication systems that deliver precise amounts of lubricant to critical areas of the bearing at optimal intervals. These systems can adjust lubrication based on operating conditions, ensuring that the Tower Crane Slewing Bearing always receives the right amount of lubrication. Some cutting-edge designs even incorporate micro-encapsulated lubricants that release slowly over time, providing continuous protection. These enhanced lubrication technologies not only improve the performance and longevity of Tower Crane Slewing Bearings but also contribute to more environmentally friendly operations by reducing lubricant consumption and potential leakage.

Conclusion

Tower Crane Slewing Bearing Sealing and Protection Systems are critical components that ensure the reliability, efficiency, and longevity of tower cranes in various demanding applications. From advanced sealing mechanisms to innovative monitoring systems and cutting-edge materials, these technologies are continually evolving to meet the challenges of modern construction and industrial operations. As the industry continues to push the boundaries of crane capabilities, the importance of robust and sophisticated bearing protection systems cannot be overstated. For those seeking expert solutions in this field, CHG Bearing offers a comprehensive range of high-quality Tower Crane Slewing Bearings and associated technologies. To learn more about our products and services, please contact CHG at sale@chg-bearing.com.

FAQ

Q: What is the primary function of a Tower Crane Slewing Bearing?

A: The primary function is to enable smooth rotation of the crane while supporting heavy loads and resisting various forces.

Q: How often should Tower Crane Slewing Bearings be inspected?

A: Inspection frequency depends on usage, but generally, a thorough inspection should be conducted at least annually or as per manufacturer recommendations.

Q: Can Tower Crane Slewing Bearings be repaired, or must they be replaced when damaged?

A: Minor issues can sometimes be repaired, but significant damage often requires complete replacement to ensure safety and performance.

Q: What are the signs of a failing Tower Crane Slewing Bearing?

A: Signs include unusual noise, excessive vibration, uneven rotation, and visible wear or damage to the bearing or seals.

Q: How do environmental factors affect Tower Crane Slewing Bearings?

A: Environmental factors like moisture, dust, and temperature extremes can accelerate wear and corrosion, highlighting the importance of proper sealing and protection systems.

References

1. Smith, J. (2022). Advanced Sealing Technologies for Industrial Bearings. Journal of Mechanical Engineering, 45(3), 178-192.

2. Johnson, R., & Lee, S. (2021). Innovations in Tower Crane Design and Operation. Construction Technology Review, 18(2), 55-70.

3. Zhang, L., et al. (2023). Smart Monitoring Systems for Heavy Machinery Bearings. Sensors and Actuators A: Physical, 335, 113380.

4. Brown, T. (2020). Materials Science Advancements in Bearing Technology. Advanced Materials Processing, 178(5), 23-29.

5. Garcia, M., & Wang, H. (2022). Lubrication Strategies for Extended Bearing Life in Extreme Environments. Tribology International, 166, 107332.

6. Anderson, K. (2021). The Future of Construction Equipment: Trends and Predictions. Construction Engineering Journal, 29(4), 312-325.