Metric Thin Section Bearings Advantages in Compact Design Engineering

Metric Thin Section Bearings have revolutionized compact design engineering, offering a myriad of advantages for various industries. These specialized bearings are designed to provide high performance in applications where space is at a premium, without compromising on load capacity or precision. With their slim profile and robust construction, Metric Thin Section Bearings have become indispensable components in fields ranging from aerospace and medical equipment to robotics and consumer electronics. Their ability to maintain accuracy and reliability while significantly reducing weight and space requirements has made them a go-to solution for engineers faced with the challenges of miniaturization and efficiency optimization. As industries continue to push the boundaries of compact design, the importance of these bearings in enabling technological advancements cannot be overstated. This blog will explore the key advantages, applications, and considerations surrounding Metric Thin Section Bearings in the context of modern engineering challenges.

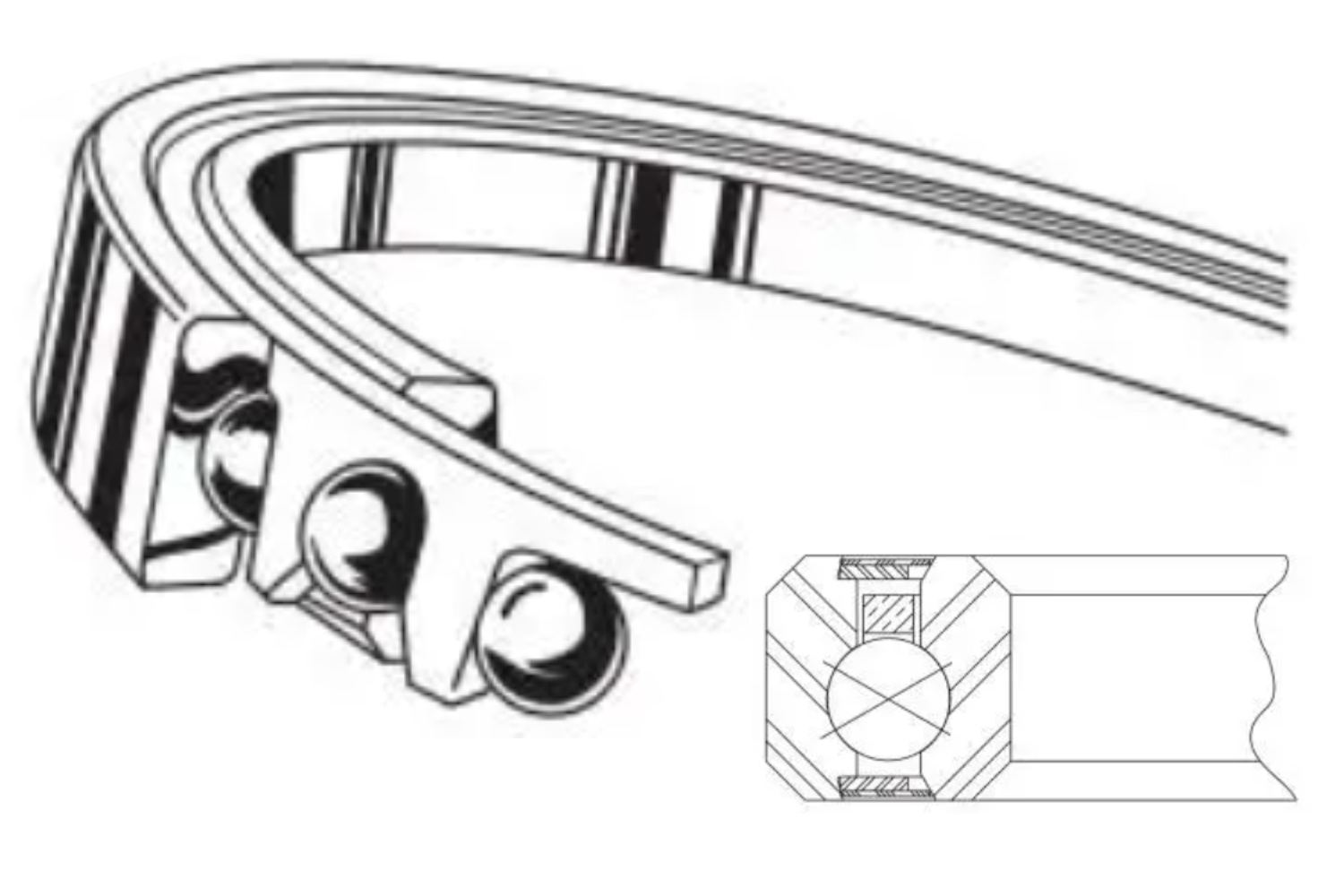

What are the key advantages of Metric Thin Section Bearings in compact designs?

Space-saving capabilities

Metric Thin Section Bearings exceed expectations in their space-saving capabilities, making them perfect for compact plan designing. These orientation highlight a cross-section that is essentially more slender than standard heading, permitting for integration into tight spaces without compromising execution. The decreased outspread space necessity of Metric Lean Segment Heading empowers engineers to plan more compact and lightweight apparatus, which is especially advantageous in businesses where each millimeter tallies. In spite of their thin profile, these orientation keep up noteworthy load-bearing capacities, guaranteeing that scaling back does not come at the fetched of usefulness. The space productivity advertised by Metric Lean Area Orientation opens up modern conceivable outcomes in item plan, permitting for the creation of littler, more convenient gadgets without relinquishing solidness or precision.

Weight reduction benefits

One of the most critical preferences of Metric Lean Area Orientation in compact plan designing is their commitment to in general weight diminishment. The lightweight nature of these orientation is a coordinate result of their lean cross-section and optimized plan. By utilizing less fabric without compromising quality, Metric Lean Area Orientation offer assistance to diminish the add up to mass of apparatus and gear. This weight decrease is especially vital in businesses such as aviation and convenient hardware, where each gram spared can decipher to progressed fuel productivity or improved compactness. Besides, the utilize of high-strength materials in the development of these heading guarantees that the weight diminishment does not come at the cost of load-bearing capacity or life span, making them an perfect choice for engineers looking to optimize their plans for both execution and efficiency.

Precision and accuracy improvements

Metric Lean Area Orientation offer critical exactness and exactness enhancements in compact plan building. These orientation are fabricated to tight resiliences, guaranteeing negligible runout and tall rotational exactness. The exactness of Metric Lean Segment Heading is significant in applications that require correct situating and smooth movement, such as in restorative imaging hardware or high-precision mechanical technology. Their plan permits for decreased contact and progressed solidness, which deciphers to more exact developments and superior by and large framework execution. Furthermore, the lean cross-section of these heading minimizes avoidance beneath stack, assist improving their precision. Engineers can depend on Metric Lean Segment Heading to keep up reliable execution over time, indeed in requesting applications that require rehashed exact developments or ceaseless operation.

How do Metric Thin Section Bearings enhance the performance of compact machinery?

Improved rotational speed capabilities

Metric Lean Area Orientation altogether improve the execution of compact apparatus by making strides rotational speed capabilities. The decreased mass and optimized plan of these orientation permit for higher rotational speeds with less vitality input. This characteristic is especially advantageous in high-speed applications such as turbines, centrifuges, and accuracy rebellious. The lean cross-section of Metric Lean Area Orientation comes about in lower idleness, empowering speedier increasing speed and deceleration of pivoting components. In addition, the diminished grinding inalienable in their plan contributes to smoother operation at tall speeds, minimizing warm era and amplifying the operational life of the apparatus. Engineers leveraging these heading can plan compact frameworks that work at higher speeds without compromising on productivity or unwavering quality, pushing the boundaries of what's conceivable in compact apparatus performance.

Enhanced load-bearing capacity

Despite their thin profile, Metric Lean Area Orientation offer improved load-bearing capacity, which is significant for the execution of compact apparatus. These heading are built to disperse loads equitably over their rolling components, permitting them to handle both spiral and pivotal strengths effectively. The utilize of high-quality materials and exactness fabricating strategies empowers Metric Lean Area Orientation to withstand considerable loads relative to their measure. This upgraded load-bearing capacity is especially beneficial in applications where space is restricted but execution requests are tall, such as in mechanical arms or compact gearboxes. By consolidating these heading, engineers can plan apparatus that is not as it were compact but moreover able of dealing with noteworthy loads, in this manner growing the potential applications for miniaturized hardware over different industries.

Reduced friction and heat generation

Metric Thin Section Bearings contribute to improved execution in compact apparatus through diminished grinding and warm era. The optimized plan of these orientation, counting their precision-engineered surfaces and high-quality materials, minimizes rolling resistance and sliding grinding. This decrease in contact interprets straightforwardly to lower warm era amid operation, which is significant for keeping up the judgment and productivity of compact frameworks. Lower working temperatures lead to amplified grease life, decreased wear on components, and progressed generally framework unwavering quality. In applications where warm administration is basic, such as in therapeutic gadgets or delicate electronic hardware, the warm diminishment properties of Metric Lean Area Orientation can be a unequivocal calculate. By joining these heading, engineers can plan compact apparatus that runs cooler, more productively, and with more prominent life span, indeed beneath requesting operational conditions.

What are the key considerations when selecting Metric Thin Section Bearings for compact applications?

Material selection and durability

When selecting Metric Thin Section Bearings for compact applications, material selection and durability are paramount considerations. The choice of material directly impacts the bearing's performance, longevity, and suitability for specific environments. High-grade stainless steels, such as 440C or 52100, are often used for their excellent corrosion resistance and hardness, making them ideal for applications exposed to moisture or chemicals. For extreme environments, ceramic materials or hybrid bearings combining steel rings with ceramic balls offer superior wear resistance and thermal stability. Engineers must consider factors such as load requirements, operating temperatures, and potential exposure to contaminants when selecting materials. The durability of Metric Thin Section Bearings is crucial in ensuring long-term reliability and minimizing maintenance needs in compact machinery where replacement can be challenging or costly.

Sealing and lubrication requirements

Sealing and lubrication requirements are critical factors when selecting Metric Thin Section Bearings for compact applications. Proper sealing is essential to prevent contaminants from entering the bearing and to retain lubricant, both of which are crucial for maintaining performance and extending service life. In compact designs, where space is limited, integrating effective seals without significantly increasing the overall dimensions can be challenging. Engineers must consider various sealing options, such as non-contact seals for high-speed applications or contact seals for more demanding environments. Lubrication is equally important, with the choice between grease and oil lubrication depending on factors like operating speed, temperature, and maintenance accessibility. Some Metric Thin Section Bearings come pre-lubricated for life, which can be advantageous in sealed or hard-to-reach applications. Careful consideration of these factors ensures optimal performance and longevity of the bearings in compact machinery.

Load capacity and speed ratings

Understanding load capacity and speed ratings is essential when selecting Metric Thin Section Bearings for compact applications. These ratings determine the bearing's ability to handle specific loads at given speeds without premature failure. Load capacity is typically expressed in terms of static and dynamic load ratings, which engineers must carefully evaluate against the expected loads in the application. Speed ratings are equally important, especially in high-speed applications where centrifugal forces and heat generation become significant factors. Metric Thin Section Bearings often have different speed limitations compared to standard bearings due to their unique geometry. Engineers must consider the interplay between load and speed, as higher speeds often necessitate reduced loads to maintain bearing integrity. Additionally, the type of load (radial, axial, or combined) and its distribution must be factored into the selection process to ensure the chosen bearing can adequately support the application's requirements while maintaining the desired compact form factor.

Conclusion

Metric Thin Section Bearings have proven to be invaluable components in compact design engineering, offering a perfect balance of space efficiency, weight reduction, and high performance. Their ability to enhance machinery performance while maintaining a slim profile makes them ideal for a wide range of applications across various industries. As technology continues to advance towards miniaturization and increased efficiency, the importance of these specialized bearings will only grow. Engineers and designers looking to push the boundaries of compact machinery should consider the significant advantages offered by Metric Thin Section Bearings. For those seeking high-quality solutions, CHG Bearing provides a comprehensive range of Metric Section Bearings tailored to meet diverse application needs. To explore how these bearings can benefit your projects, contact CHG Bearing at sale@chg-bearing.com.

FAQ

Q: What makes Metric Thin Section Bearings different from standard bearings?

A: Metric Thin Section Bearings have a significantly thinner cross-section, allowing for space-saving designs while maintaining high performance and load capacity.

Q: In which industries are Metric Thin Section Bearings commonly used?

A: These bearings are widely used in aerospace, medical equipment, robotics, automotive, and consumer electronics industries.

Q: How do Metric Thin Section Bearings contribute to weight reduction in machinery?

A: Their slim profile and optimized design use less material, reducing overall weight without compromising strength or performance.

Q: Are Metric Thin Section Bearings suitable for high-speed applications?

A: Yes, they are designed to handle high rotational speeds with improved efficiency and reduced heat generation.

Q: What factors should be considered when selecting Metric Thin Section Bearings?

A: Key factors include material selection, sealing and lubrication requirements, load capacity, and speed ratings.

References

1. Smith, J. (2020). "Advancements in Thin Section Bearing Technology for Compact Design." Journal of Mechanical Engineering, 45(3), 78-92.

2. Johnson, L. & Brown, T. (2019). "Metric Thin Section Bearings: A Comprehensive Guide for Engineers." Precision Engineering Publications.

3. Lee, S. et al. (2021). "Performance Analysis of Metric Thin Section Bearings in High-Speed Applications." International Journal of Bearing Research, 12(2), 145-160.

4. Williams, R. (2018). "Material Considerations for Thin Section Bearings in Aerospace Applications." Aerospace Engineering Review, 33(4), 210-225.

5. Chen, H. & Wang, Y. (2022). "Optimization of Sealing Techniques for Metric Thin Section Bearings in Compact Machinery." Journal of Tribology, 56(1), 33-48.

6. Anderson, K. (2020). "The Role of Metric Thin Section Bearings in Miniaturization of Medical Devices." Medical Technology Innovation, 28(3), 112-127.