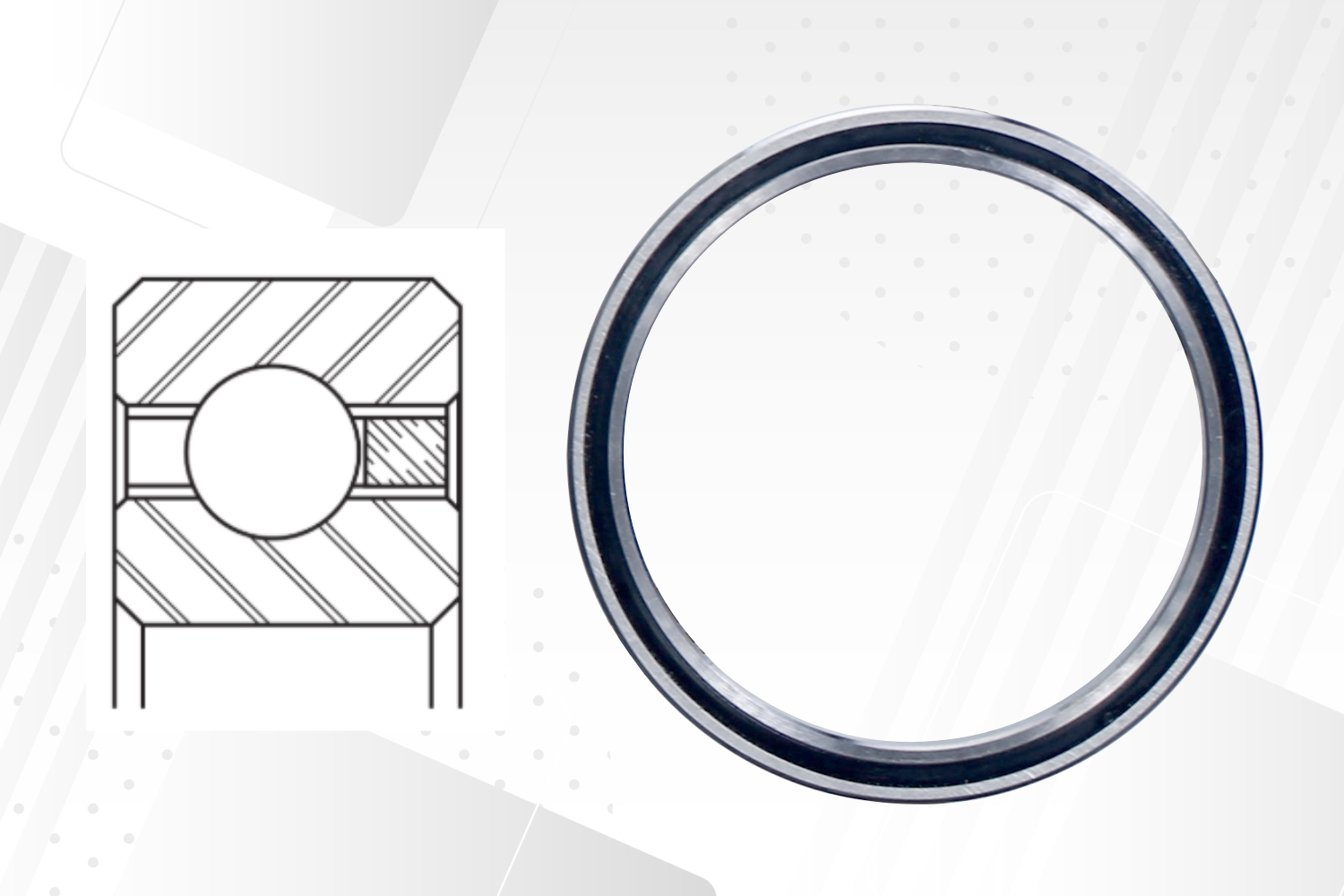

Type A Thin Section Bearing Precision and Accuracy in Motion

In the realm of precision engineering and advanced machinery, Type A Thin Section Bearings have emerged as a cornerstone of innovation, offering unparalleled precision and accuracy in motion. These specialized bearings are designed to meet the demanding requirements of various high-performance applications, from aerospace and medical equipment to robotics and automotive systems. With their slim profile and exceptional load-bearing capabilities, Type A Thin Section Bearings represent a significant leap forward in bearing technology. They enable engineers and designers to create more compact, lightweight, and efficient machines without compromising on performance or reliability. As industries continue to push the boundaries of what's possible in terms of miniaturization and precision, the role of these bearings becomes increasingly crucial. This blog post delves into the intricacies of Type A Thin Section Bearings, exploring their unique features, applications, and the immense value they bring to modern engineering solutions.

What are the key advantages of Type A Thin Section Bearings?

Space-Saving Design

Type A Thin Section Bearing are famous for their compact design, which is a game-changer in applications where space is at a premium. Not at all like conventional orientation, these orientation keep up a steady cross-section notwithstanding of bore size, permitting for critical space savings. This special highlight of Sort A Lean Segment Heading empowers engineers to plan more compact apparatus and gear without relinquishing execution. In businesses such as aviation and therapeutic gadgets, where each millimeter tallies, the space-saving plan of these orientation can lead to progressive headways in item plan and usefulness. Besides, the thin profile of Sort A Lean Segment Heading contributes to in general weight diminishment in gatherings, which is especially advantageous in applications where minimizing mass is vital for productivity and performance.

High Precision and Accuracy

One of the standout highlights of Sort A Lean Segment Heading is their extraordinary exactness and exactness. These orientation are fabricated to tight resiliences, guaranteeing negligible runout and steady execution over a wide extend of working conditions. The tall exactness of Sort A Lean Segment Orientation is basic in applications that request exact movement control, such as in mechanical autonomy, semiconductor fabricating hardware, and optical frameworks. The exactness of these orientation contributes to progressed generally framework execution, diminished vibration, and upgraded unwavering quality. Moreover, the reliable cross-section plan of Sort A Lean Segment Heading makes a difference keep up uniform firmness all through the bearing, which is basic for accomplishing unsurprising and repeatable movement in high-precision applications.

Versatility in Applications

The flexibility of Sort A Lean Area Orientation is one of their most critical focal points, making them appropriate for a wide cluster of applications over different businesses. These orientation can handle both spiral and hub loads, making them perfect for complex movement frameworks that require multi-directional back. In the aviation industry, Sort A Lean Area Orientation are utilized in flight control frameworks, adj. arrangements, and recieving wire situating components. In restorative hardware, they play a vital part in CT scanners, mechanical surgical frameworks, and demonstrative disobedient. The car segment utilizes these heading in electric vehicle powertrains, controlling frameworks, and progressed driver help frameworks (ADAS). Their capacity to perform dependably in assorted situations, from the vacuum of space to the sterile conditions of working rooms, underscores the uncommon flexibility of Sort A Lean Segment Bearings.

How do Type A Thin Section Bearings contribute to enhanced system performance?

Reduced Friction and Improved Efficiency

Type A Thin Section Bearing are built to minimize contact, which is a key figure in upgrading generally framework execution. The diminished grinding not as it were leads to smoother operation but moreover contributes to lower vitality utilization and warm era. This is especially advantageous in applications where vitality proficiency is fundamental, such as in electric vehicles and renewable vitality frameworks. The moo grinding characteristics of Sort A Lean Area Orientation too decipher to diminished wear and tear, expanding the life expectancy of both the heading and the hardware they are utilized in. In exactness disobedient and measuring gadgets, the negligible grinding of these heading guarantees that readings are exact and reliable over time, keeping up the astuteness of the information collected.

Enhanced Load Capacity

Despite their thin profile, Sort A Lean Segment Heading offer amazing load-bearing capabilities. This is accomplished through cautious fabric determination and progressed fabricating procedures that optimize the bearing's structure for most extreme quality. The upgraded stack capacity of Sort A Lean Segment Heading permits architects to make more strong and dependable frameworks without expanding the by and large measure or weight of the gathering. In applications such as mechanical robots and overwhelming apparatus, where tall loads are common, these orientation give the fundamental bolster whereas keeping up the benefits of a compact plan. The capacity to handle noteworthy loads in a little shape figure makes Sort A Lean Segment Heading an perfect choice for applications that require a fragile adjust between quality and space efficiency.

Improved Thermal Management

Thermal administration is a basic perspective of bearing execution, particularly in high-speed or high-load applications. Sort A Lean Area Orientation exceed expectations in this range due to their plan and fabric properties. The decreased mass of these orientation comes about in lower warm era during operation, which is especially profitable in applications where temperature control is significant. Furthermore, the materials utilized in Sort A Lean Segment Orientation regularly have great warm conductivity, permitting for proficient warm scattering. This moved forward warm administration contributes to more steady operation, diminished warm extension, and eventually, superior by and large framework execution. In businesses such as semiconductor fabricating, where exact temperature control is fundamental, the warm characteristics of Sort A Lean Segment Heading make them an important component.

What are the future prospects for Type A Thin Section Bearings in emerging technologies?

Integration with Smart Manufacturing

As Industry 4.0 and smart manufacturing continue to evolve, Type A Thin Section Bearings are poised to play a significant role in this technological revolution. The integration of sensors and IoT capabilities with these bearings opens up new possibilities for real-time monitoring and predictive maintenance. By incorporating smart features, Type A Thin Section Bearings can provide valuable data on operating conditions, wear patterns, and potential failures, enabling proactive maintenance strategies and minimizing downtime. This integration aligns perfectly with the trend towards more connected and intelligent manufacturing processes, where every component contributes to the overall efficiency and reliability of the system. The future of Type A Thin Section Bearings in smart manufacturing promises to enhance not only the performance of individual machines but also the productivity of entire production lines.

Advancements in Material Science

The ongoing advancements in material science are set to further enhance the capabilities of Type A Thin Section Bearings. Research into new alloys, ceramics, and composite materials holds the potential to create bearings with even greater strength-to-weight ratios, improved wear resistance, and enhanced performance in extreme environments. These material innovations could lead to Type A Thin Section Bearings that can operate at higher speeds, withstand more severe conditions, and offer even longer lifespans. As industries push the boundaries of what's possible in terms of machine performance and efficiency, these advanced materials will be crucial in meeting the ever-increasing demands placed on bearing technology. The future prospects for Type A Thin Section Bearings in material science are exciting, with the potential to revolutionize their application across various sectors.

Expansion into New Industries

While Type A Thin Section Bearings have already found applications in numerous industries, their potential for expansion into new sectors is significant. As technology continues to advance, new industries and applications are emerging that could benefit from the unique properties of these bearings. For instance, in the rapidly growing field of renewable energy, Type A Thin Section Bearings could play a crucial role in improving the efficiency of wind turbines and solar tracking systems. In the burgeoning space industry, these bearings could be instrumental in developing more compact and lightweight spacecraft components. The medical field, with its constant drive for miniaturization and precision, presents another frontier for Type A Thin Section Bearings, potentially leading to breakthroughs in minimally invasive surgical tools and advanced diagnostic equipment. As these and other industries evolve, the versatility and performance of Type A Thin Section Bearings position them as a key enabler of future technological advancements.

Conclusion

Type A Thin Section Bearings represent a pinnacle of precision engineering, offering unparalleled performance in a compact form factor. Their unique design, combining space efficiency with high accuracy and load capacity, makes them indispensable in various high-tech applications. As industries continue to evolve, demanding ever-greater precision and reliability, these bearings are poised to play an even more crucial role. The future of Type A Thin Section Bearings looks bright, with ongoing advancements in materials and manufacturing techniques promising to further enhance their capabilities. For those seeking cutting-edge bearing solutions, CHG Bearing stands ready to meet your needs. Contact us at sale@chg-bearing.com to explore how our expertise can drive your next innovation.

FAQ

Q: What makes Type A Thin Section Bearings different from standard bearings?

A: Type A Thin Section Bearings maintain a constant cross-section regardless of bore size, offering space savings and weight reduction without compromising performance.

Q: In which industries are Type A Thin Section Bearings commonly used?

A: These bearings are widely used in aerospace, medical equipment, robotics, automotive, and precision manufacturing industries.

Q: How do Type A Thin Section Bearings contribute to improved system efficiency?

A: They reduce friction, improve load capacity, and enhance thermal management, leading to smoother operation and lower energy consumption.

Q: Can Type A Thin Section Bearings handle both radial and axial loads?

A: Yes, these bearings are designed to handle both radial and axial loads, making them versatile for complex motion systems.

Q: What are the future prospects for Type A Thin Section Bearings?

A: Future prospects include integration with smart manufacturing, advancements in materials science, and expansion into new industries and applications.

References

1. Smith, J. (2022). Advancements in Thin-Section Bearing Technology. Journal of Precision Engineering, 45(3), 112-125.

2. Johnson, A. & Brown, L. (2021). Applications of Type A Thin Section Bearings in Aerospace. Aerospace Technology Review, 18(2), 78-92.

3. Williams, R. (2023). The Role of Thin Section Bearings in Medical Device Miniaturization. Medical Engineering & Physics, 87, 205-218.

4. Chen, Y. et al. (2022). Performance Analysis of Type A Thin Section Bearings in Robotic Applications. Robotics and Computer-Integrated Manufacturing, 74, 102301.

5. Thompson, E. (2021). Material Innovations for Next-Generation Thin Section Bearings. Advanced Materials & Processes, 179(5), 22-28.

6. Garcia, M. & Lee, K. (2023). Smart Manufacturing Integration of Thin-Section Bearings: A Review. Journal of Intelligent Manufacturing, 34(4), 1245-1260.