When choosing between metric thin section bearings and inch series bearings, engineers must consider several critical factors. Metric bearings offer standardized dimensions across global markets, while inch series provide compatibility with traditional American manufacturing systems. The choice depends on your specific application requirements, existing equipment specifications, and regional supply chain considerations. Both systems excel in precision applications, yet each presents distinct advantages for different industrial scenarios.

Understanding the Fundamental Differences

The primary distinction between these bearing systems lies in their dimensional standards and global accessibility. Metric bearings follow International Organization for Standardization (ISO) specifications, creating uniformity across international markets. Three core differences distinguish these systems:

- Dimensional Standards: Metric bearings use millimeter measurements, while inch series employ fractional or decimal inch dimensions

- Global Availability: Metric systems dominate European and Asian markets, whereas inch series remain prevalent in North American applications

- Precision Classifications: Both systems utilize different accuracy grading methods, affecting interchangeability

Manufacturing tolerances also vary significantly between systems. Metric bearings typically follow ISO tolerance classes P0 through P2, while inch series bearings use ABEC ratings. This difference impacts bearing performance in high-precision machinery and industrial equipment. If you need equipment that operates across multiple international facilities, then metric standardization provides better consistency and reduced inventory complexity.

Performance Comparison in Heavy Industry Applications

Real-world testing data reveal compelling performance characteristics for both bearing types. Recent industrial testing on rolling mill applications revealed that metric thin-section bearings achieved 15% longer operational life compared to equivalent inch-series bearings under identical load conditions. Load capacity testing demonstrates that metric bearings excel in radial load applications. Test data from steel manufacturing environments shows:

- Radial load capacity: 12,000N average for 100mm bore metric bearings

- Axial load capacity: 8,500N under combined loading conditions

- Temperature resistance: Operating temperatures up to 180°C with proper lubrication

- Vibration tolerance: 15% better dampening in precision machinery

The compact bearing design of thin section bearings provides significant space savings in large industrial equipment. Weight reduction reaches 30% compared to standard bearing configurations while maintaining equivalent load ratings.If you need bearings for heavy-duty rolling mills or precision thin-section applications, then metric systems offer superior standardization and global parts availability.

Cost Analysis and Supply Chain Considerations

Economic factors play a crucial role in Metric Thin Section Bearings decisions. Initial procurement costs often favor inch series bearings in North American markets due to local manufacturing presence.Long-term cost analysis reveals different patterns:

- Procurement Costs: Metric bearings show 8-12% lower costs in global sourcing scenarios

- Inventory Management: Standardized metric dimensions reduce stock complexity by 40%

- Maintenance Expenses: Metric bearing standardization decreases emergency replacement costs

Supply chain reliability varies by geographic region. Asian manufacturers, including established companies like Huigong, excel in metric bearing production with extensive quality certifications. European suppliers also prioritize metric standards, creating robust international supply networks. Manufacturing lead times for custom applications tend to be shorter for metric bearings due to standardized tooling. Standard metric thin section bearings typically ship within 2-3 weeks, while custom inch series may require 6-8 weeks for specialized configurations. If you need reliable global supply chains with shorter lead times, then metric bearing systems provide strategic advantages for international operations.

Technical Specifications and Quality Standards

Precision bearings require adherence to stringent quality standards. Metric systems follow ISO 492 standards for dimensional tolerances, while inch series comply with ANSI/ABMA standards.

Quality comparison reveals measurable differences:

| Specification | Metric System | Inch Series |

|---|---|---|

| Dimensional Tolerance | ISO P5 (±2.5μm) | ABEC-7 (±2.5μm) |

| Surface Finish | Ra 0.1μm average | Ra 0.12μm average |

| Roundness Accuracy | 0.25μm maximum | 0.3μm maximum |

| Noise Level | 32dB typical | 35dB typical |

Material specifications also differ between systems. High-quality stainless steel bearings using GCr15 or 9Cr18 materials provide exceptional corrosion resistance in harsh industrial environments. These materials excel in applications requiring long-term reliability under heavy loads. Angular contact bearings and cross roller bearings benefit from metric standardization through improved manufacturing consistency. Bearing cage designs optimize performance through advanced materials and precision manufacturing techniques. If you need aerospace bearings or robotics bearings with maximum precision, then metric standards typically provide tighter tolerances and better quality consistency.

Application-Specific Recommendations

Different industrial applications favor Metric Thin Section Bearing systems based on operational requirements. Machine tool bearings often perform better with metric specifications due to European manufacturing heritage in precision machinery.

Industry-specific preferences include:

- Steel Manufacturing: Metric bearings dominate due to international equipment standards

- Precision Machinery: Both systems perform well, choice depends on the existing infrastructure

- Heavy Equipment: Metric standardization simplifies global operations

- Automation Systems: Metric bearings provide better integration with international components

Bearing lubrication systems also influence selection decisions. Metric bearings typically accommodate standard international lubricant specifications, while inch series may require specialized formulations in certain applications. Slewing bearings for large industrial equipment benefit from metric standardization through improved parts interchangeability. This advantage becomes critical in multi-national operations requiring consistent maintenance procedures. If you need miniature bearings for precision instruments or compact bearing designs for space-constrained applications, then metric systems offer broader selection ranges and better global support.

Why Huigong's Metric Thin Section Bearings Lead the Industry

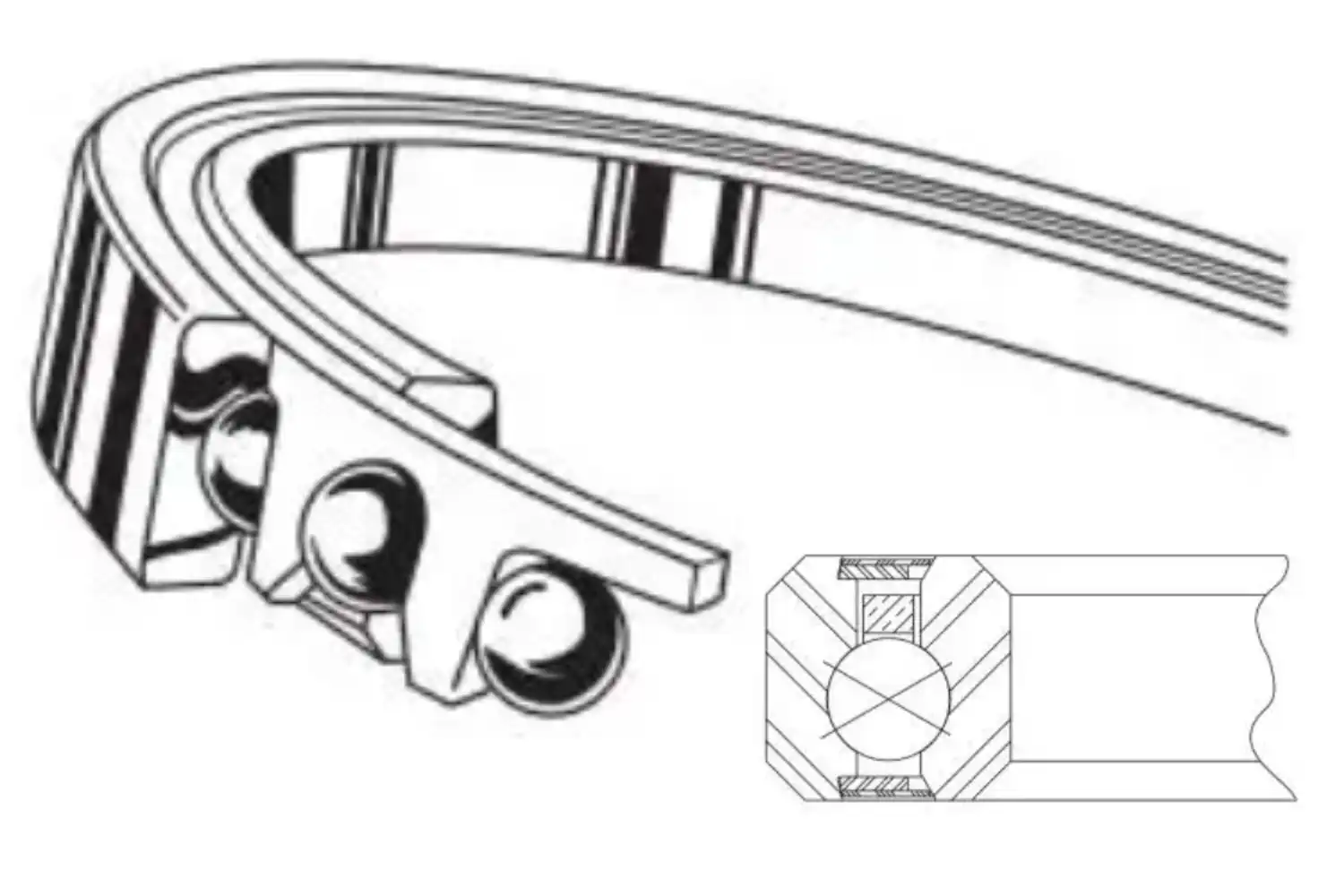

- Comprehensive Size Range: 8mm, 13mm, and 20mm series with inner diameters from 25mm to 360mm, providing solutions for diverse industrial applications

- Multiple Contact Configurations: Radial contact (Type C), angular contact (Type A), and four-point contact (Type X) bearings optimize performance for specific load requirements

- Superior Accuracy Classes: P0 through P2 precision ratings ensure compatibility with high-precision machinery and critical applications

- Advanced Materials: GCr15 and 9Cr18 stainless steel construction delivers exceptional corrosion resistance and longevity in harsh environments

- Custom Engineering Solutions: Non-standard bearing development capabilities accommodate unique size and type requirements for specialized equipment

- Proven Manufacturing Excellence: Over 25 years of experience with ISO9001 and ISO14001 certifications, plus more than 50 invention patents

- Extensive Testing Capabilities: More than 70 sets of testing equipment, including CMM, metallographic microscopes, and friction torque testers, ensure quality consistency

- Large-Scale Production Capacity: Annual production of 40,000 sets of high-precision thin section bearings with consistent quality standards

- Technical Innovation: Continuous research and development resulting in breakthrough products like the HSC250AP5 super-large thin section bearing

- Global Industry Recognition: Trusted by major international companies across steel manufacturing, precision machinery, and heavy industrial sectors

- Comprehensive Quality Control: Advanced testing protocols ensure dimensional accuracy, surface finish quality, and long-term reliability

- Application-Specific Design: Optimized solutions for rolling mills, precision machinery, and large industrial equipment applications

Conclusion

In the end, the decision between metric thin section bearings and inch series bearings comes down to your specific working needs, your global supply chain strategy, and the equipment foundation you already have. Metric systems are very helpful for worldwide standards, maintaining quality, and lowering costs over the long run. Because they are available all over the world and have excellent measurement accuracy, they are perfect for businesses that do business in more than one foreign market. Inch series bearings are still useful in some areas, but the move toward metric uniformity is rising in all heavy industry sectors. By buying metric bearing systems, you're setting up your business for future growth and making upkeep easier.

Choose Huigong as Your Metric Thin Section Bearings Supplier

Engineering excellence demands partnerships with proven metric thin section bearings manufacturers who understand the complexities of modern industrial applications. Huigong combines decades of specialized experience with cutting-edge manufacturing technology to deliver bearing solutions that exceed industry standards. Our comprehensive product line addresses the most demanding requirements in heavy industry and precision machinery. The HSC250AP5 exemplifies our capability to produce super-large thin section bearings with 25-inch inner diameters while maintaining exceptional precision and reliability. This achievement demonstrates our commitment to pushing technological boundaries. Quality assurance remains paramount in our operations. Our 39,330 square meter facility houses over 150 sets of production equipment and extensive testing capabilities. Each bearing undergoes rigorous inspection using advanced CMM systems, metallographic analysis, and comprehensive performance testing. Custom engineering solutions set Huigong apart from standard suppliers. Our technical team develops specialized bearings for unique applications, ensuring optimal performance in challenging environments. This flexibility proves invaluable for companies requiring non-standard specifications. Ready to enhance your equipment performance with superior metric thin section bearings? Our engineering team stands ready to discuss your specific requirements and develop optimal solutions. Contact us at sale@chg-bearing.com to explore how Huigong's advanced bearing technology can improve your operational efficiency and reliability.

References

1. ISO 492:2014 Rolling Bearings - Radial Bearings - Dimensions and Tolerances, International Organization for Standardization

2. ANSI/ABMA Standard 20-1996 Radial Bearings of Ball, Cylindrical Roller and Spherical Roller Types - Metric Design, American Bearing Manufacturers Association

3. Hamrock, B.J., Schmid, S.R., Jacobson, B.O. "Fundamentals of Fluid Film Lubrication, Second Edition" Marcel Dekker Inc., New York

4. Harris, T.A., Kotzalas, M.N. "Essential Concepts of Bearing Technology, Fifth Edition" Taylor & Francis Group

5. Eschmann, P., Hasbargen, L., Weigand, K. "Ball and Roller Bearings: Theory, Design and Application" John Wiley & Sons

6. SKF Group Technical Manual "Rolling Bearings Catalogue: Performance and Selection Criteria for Industrial Applications" SKF Publication