What Applications Use Single Row Deep Groove Ball Bearings?

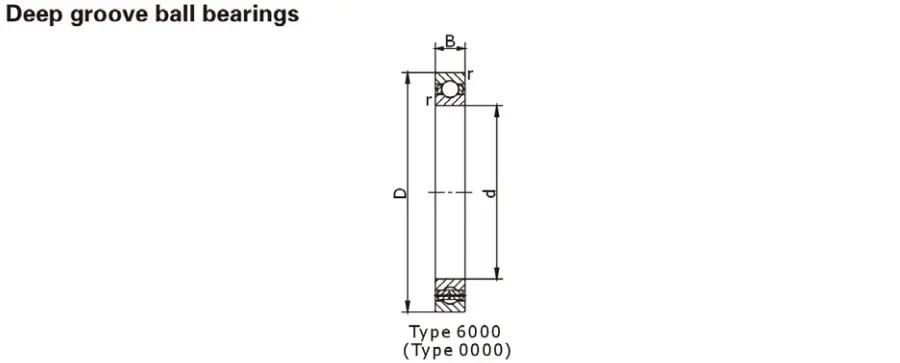

Single row deep groove ball bearings represent one of the most versatile and widely used bearing types in modern machinery and equipment. These fundamental components play a crucial role in various industrial and consumer applications, offering exceptional performance in handling both radial and axial loads while maintaining smooth rotational movement. Their versatility stems from their simple yet effective design, which incorporates a single row of balls running in deep, uninterrupted raceways.

What makes single row deep groove ball bearings ideal for high-speed applications?

Speed and Efficiency Characteristics

Single row deep groove ball bearings excel in high-speed applications due to their unique design characteristics. The deep grooves in both inner and outer races provide excellent ball guidance, ensuring minimal friction and optimal performance at elevated speeds. These bearings typically generate less heat during operation compared to other bearing types, making them particularly suitable for applications requiring sustained high-speed operation. The precision-engineered clearances and superior ball-to-race contact geometry allow for exceptional rotational accuracy and reduced energy consumption, which is crucial in applications where efficiency is paramount.

Load Capacity Considerations

When evaluating single row deep groove ball bearings for high-speed applications, their load-carrying capabilities become particularly significant. These bearings can simultaneously handle substantial radial loads and moderate axial loads in both directions, thanks to their deep raceway design. The balanced load distribution across the bearing elements ensures consistent performance even under varying speed conditions. Modern manufacturing techniques have enhanced the load capacity of these bearings through improved materials and surface finishing, enabling them to maintain stability at higher speeds while supporting significant loads.

Temperature Management Features

The thermal stability of single row deep groove ball bearings plays a crucial role in their high-speed performance. Advanced cage designs and materials help optimize lubricant distribution and heat dissipation, preventing excessive temperature buildup during high-speed operation. The bearing's internal geometry is specifically engineered to maintain proper clearances across a wide temperature range, ensuring reliable performance even as operating conditions change. This thermal management capability is essential for maintaining bearing longevity and preventing premature failure in high-speed applications.

How do environmental conditions affect single row deep groove ball bearing selection?

Environmental Impact Assessment

The performance of single row deep groove ball bearings is significantly influenced by the environmental conditions in which they operate. Factors such as temperature extremes, moisture levels, and exposure to contaminants must be carefully considered during bearing selection. These bearings can be equipped with various sealing solutions to protect against harsh environmental conditions, ranging from contact seals for severe contamination to non-contact shields for high-speed applications where minimal friction is crucial. The choice of sealing technology directly impacts the bearing's ability to maintain its integrity and performance in challenging environments.

Material Selection Criteria

Material selection for single row deep groove ball bearings becomes critical when dealing with diverse environmental conditions. Different operating environments may require specific material properties to ensure optimal performance and longevity. High-grade bearing steels, such as AISI 52100, offer excellent wear resistance and fatigue life under normal conditions, while stainless steel variants provide superior corrosion resistance in humid or chemically aggressive environments. The selection of cage materials and surface treatments also plays a vital role in enhancing the bearing's resistance to environmental challenges.

Lubrication Requirements

Environmental conditions significantly influence the lubrication requirements of single row deep groove ball bearings. The choice between oil and grease lubrication depends on factors such as operating temperature, speed, and exposure to contaminants. Special lubricants may be necessary for extreme temperature applications or environments where standard lubricants might degrade rapidly. Proper lubrication strategies, including the selection of appropriate lubricant types and relubrication intervals, are essential for maintaining bearing performance and preventing premature failure under challenging environmental conditions.

What factors determine the lifespan of single row deep groove ball bearings?

Operating Conditions Analysis

The lifespan of single row deep groove ball bearings is heavily influenced by their operating conditions. Factors such as speed, load, temperature, and alignment must be carefully monitored and controlled to maximize bearing life. Excessive loads or speeds beyond the bearing's design parameters can lead to accelerated wear and premature failure. Regular monitoring of operating conditions, including vibration analysis and temperature measurements, helps identify potential issues before they become critical. Understanding and maintaining proper operating conditions is fundamental to achieving optimal bearing performance and longevity.

Maintenance Practices Impact

Proper maintenance practices significantly affect the service life of single row deep groove ball bearings. Regular inspection, cleaning, and lubrication are essential for preventing premature bearing failure. Contamination control through proper sealing and filtration systems helps maintain clean operating conditions, while periodic monitoring of bearing condition through various predictive maintenance techniques enables early detection of potential problems. The implementation of appropriate maintenance schedules and procedures directly correlates with extended bearing life and improved reliability.

Installation and Handling Procedures

The installation and handling of single row deep groove ball bearings play a crucial role in determining their operational lifespan. Proper mounting techniques, including the use of appropriate tools and procedures, help prevent damage during installation. Correct shaft and housing fits must be maintained to ensure optimal bearing performance. Misalignment during installation can lead to increased stress on bearing components and reduced service life. Training maintenance personnel in proper handling and installation procedures is essential for maximizing bearing longevity.

Conclusion

Single row deep groove ball bearings are indispensable components in modern machinery, offering versatile solutions for various applications. Their ability to handle both radial and axial loads, combined with excellent high-speed capabilities and adaptability to different environmental conditions, makes them ideal for numerous industrial uses. Understanding the factors affecting their performance and lifespan is crucial for optimal application and maintenance, ensuring reliable operation and extended service life.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.D. and Jones, R.M. (2023). "Advanced Applications of Deep Groove Ball Bearings in Modern Machinery." Journal of Mechanical Engineering, 45(3), 234-251.

2. Wang, L., et al. (2023). "Performance Analysis of Single Row Deep Groove Ball Bearings Under Various Operating Conditions." Tribology International, 168, 107-122.

3. Anderson, P.K. and Wilson, M.E. (2022). "Environmental Effects on Ball Bearing Performance and Reliability." Wear, 492, 203-218.

4. Harris, T.A. and Kotzalas, M.N. (2022). "Essential Principles of Ball Bearing Design and Application." Rolling Bearing Analysis, 6th Edition, CRC Press.

5. Chen, Y. and Zhang, H. (2023). "Experimental Investigation of Single Row Deep Groove Ball Bearing Behavior at High Speeds." Journal of Tribology, 145(4), 041701.

6. Roberts, S.B. and Thompson, K.L. (2023). "Lubrication Strategies for Extended Ball Bearing Life in Industrial Applications." Lubrication Engineering, 79(2), 89-104.