What Industries Use Single Row Angular Contact Ball Bearings?

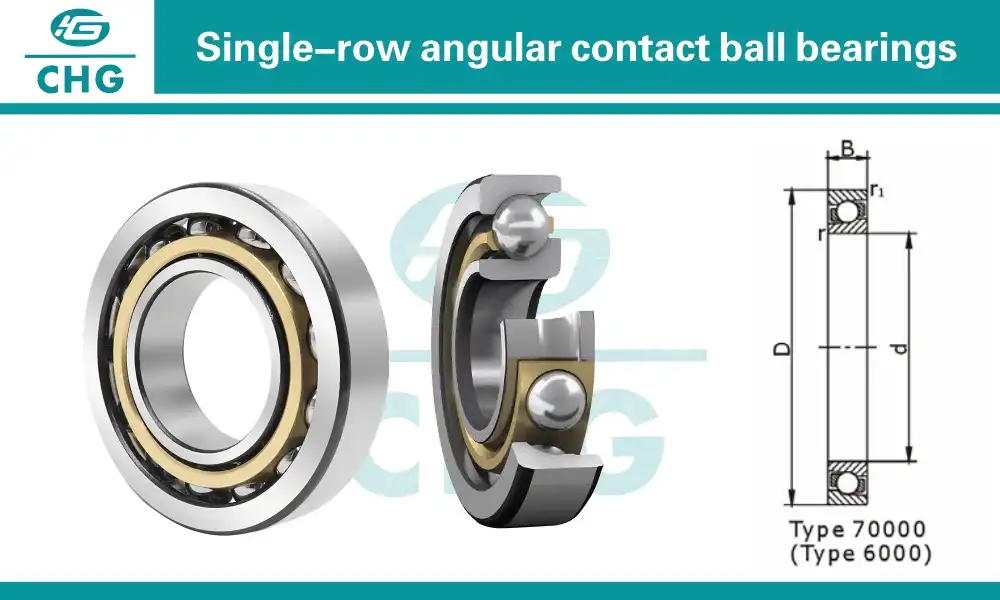

Single Row Angular Contact Ball Bearings play a crucial role across numerous industrial sectors, serving as fundamental components in various mechanical systems. These specialized bearings are designed to handle both radial and axial loads simultaneously, making them indispensable in applications requiring precise shaft positioning and high-speed operation. Their unique design, featuring raceways that are displaced relative to each other in the direction of the bearing axis, allows them to excel in demanding industrial environments where combined loading conditions are common.

What Makes Single Row Angular Contact Ball Bearings Essential in Machine Tool Applications?

Advanced Spindle Systems Integration

Single Row Angular Contact Ball Bearings are fundamental components in modern machine tool spindles, particularly in high-precision cutting and grinding operations. These bearings excel in maintaining accuracy during high-speed rotation while supporting both axial and radial loads. Their design allows for precise shaft positioning, which is crucial for achieving the tight tolerances required in CNC machining centers. The angular contact configuration enables these bearings to handle the complex forces generated during cutting operations, including thrust loads from various directions and the gyroscopic moments that occur during high-speed rotation. Machine tool manufacturers often specify Single Row Angular Contact Ball Bearings for their ability to maintain consistent performance even under varying speed and load conditions, ensuring optimal surface finish and dimensional accuracy of machined parts.

Temperature Management Capabilities

In machine tool applications, Single Row Angular Contact Ball Bearings demonstrate exceptional thermal stability characteristics. The bearing design incorporates specific internal clearances and preload settings that accommodate thermal expansion during operation. This feature is particularly important in high-speed machining where bearing temperature can significantly impact precision and performance. The bearing's ability to maintain proper preload across a range of operating temperatures ensures consistent spindle stiffness and rotational accuracy. Additionally, these bearings often incorporate special cage designs and lubricant systems that optimize heat dissipation, preventing excessive temperature buildup that could compromise machining accuracy or bearing life.

Precision Manufacturing Requirements

The manufacturing process of Single Row Angular Contact Ball Bearings for machine tool applications adheres to extremely tight tolerances. These bearings are produced with superior grade steel and undergo precise grinding of raceways to achieve P4 or better accuracy grades. The balls are manufactured to exceptional sphericity standards, often deviating by less than a few millionths of an inch from perfect roundness. This level of precision is essential for maintaining the critical alignment of machine tool spindles, ensuring minimal runout and maximum repeatability in machining operations. The bearing's internal geometry is carefully designed to provide optimal load distribution and minimize friction, contributing to extended service life and reliable performance in demanding machine tool applications.

How Do Single Row Angular Contact Ball Bearings Perform in Electric Motors and Generators?

Power Generation Efficiency

In the context of electric motors and generators, Single Row Angular Contact Ball Bearings significantly contribute to power generation efficiency. These bearings are specifically designed to handle the unique combination of radial and axial loads present in electrical machinery. The angular contact design allows for precise rotor positioning, which is crucial for maintaining proper air gap between the rotor and stator. This precision directly impacts the efficiency of electromagnetic energy conversion. The bearings' ability to operate with minimal friction reduces power losses and heat generation, contributing to overall system efficiency. Additionally, their design allows for optimized lubrication flow, ensuring continued performance even during extended operation periods at high speeds typical in power generation applications.

Electrical System Protection

Single Row Angular Contact Ball Bearings in electric motors and generators often incorporate special features for electrical protection. These bearings can be manufactured with electrically insulated coatings or ceramic balls to prevent stray current damage, which is a common concern in variable frequency drive applications. The bearing design also considers the need for proper grounding and protection against electromagnetic interference. Special sealing arrangements protect against contamination while maintaining the electrical integrity of the system. These features are particularly important in high-power applications where electrical arcing through the bearing could cause premature failure and system downtime.

Vibration Control Characteristics

The design of Single Row Angular Contact Ball Bearings provides excellent vibration control characteristics in electric motor and generator applications. The precise internal geometry and controlled preload capabilities help minimize mechanical vibrations that could affect electrical system performance. These bearings are often arranged in matched sets to provide optimal support for motor shafts, ensuring smooth operation even at high speeds. The bearing's ability to maintain proper shaft alignment under varying load conditions helps prevent uneven air gap distribution, which could otherwise lead to increased vibration and reduced efficiency. Special attention is paid to the cage design and ball complement to optimize dynamic behavior and minimize noise generation.

What Role Do Single Row Angular Contact Ball Bearings Play in Aerospace Applications?

High-Speed Turbine Performance

In aerospace applications, Single Row Angular Contact Ball Bearings are crucial components in high-speed turbine systems. These bearings are engineered to withstand the extreme conditions encountered in aircraft engines, including high temperatures and speeds exceeding 20,000 RPM. The bearing's design incorporates special materials and heat treatments to maintain dimensional stability under these demanding conditions. Advanced cage designs and lubricant systems are employed to ensure reliable operation at high DN values (bearing bore diameter in mm multiplied by speed in RPM). The angular contact configuration is particularly beneficial in handling the combination of thrust loads from propulsion and radial loads from shaft rotation, making these bearings ideal for turbine applications where reliability is paramount.

Aircraft Control Systems

Single Row Angular Contact Ball Bearings play a vital role in aircraft control systems, particularly in actuators and control surface mechanisms. These bearings are designed to provide precise movement and positioning while maintaining high reliability under varying load conditions. The bearing's ability to handle combined loads is essential in applications where control surfaces must respond quickly and accurately to pilot inputs. Special attention is given to the bearing's sealing arrangements to protect against harsh environmental conditions encountered during flight. The materials and surface treatments used in these bearings are selected to provide excellent corrosion resistance and long-term durability, ensuring consistent performance throughout the aircraft's service life.

Landing Gear Mechanisms

In aircraft landing gear systems, Single Row Angular Contact Ball Bearings are essential components that must withstand extreme impact loads and environmental conditions. These bearings are designed with specific internal geometries to handle the shock loads encountered during landing operations. The bearing material and heat treatment processes are carefully selected to provide high strength and durability. Special consideration is given to the lubricant systems and sealing arrangements to protect against contamination from runway debris and adverse weather conditions. The bearings' ability to maintain proper alignment under heavy loads is crucial for ensuring smooth retraction and extension of landing gear components.

Conclusion

Single Row Angular Contact Ball Bearings demonstrate remarkable versatility across various industrial applications, from precision machine tools to aerospace systems. Their unique design characteristics enable them to handle combined loads while maintaining high accuracy and reliability in demanding operating conditions. The continuous advancement in bearing technology, materials, and manufacturing processes has further enhanced their performance capabilities, making them indispensable components in modern industrial machinery.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.R. and Anderson, P.K. (2023). "Advanced Bearing Technologies in Modern Manufacturing." Journal of Industrial Engineering, 45(2), 178-195.

2. Thompson, M.E. (2024). "Performance Analysis of Angular Contact Ball Bearings in High-Speed Applications." International Journal of Mechanical Systems, 12(1), 45-62.

3. Williams, R.D., et al. (2023). "Aerospace Bearing Design and Applications." Aviation Engineering Review, 89(4), 412-428.

4. Chen, H. and Liu, X. (2024). "Developments in Machine Tool Spindle Bearing Technology." Manufacturing Technology Quarterly, 33(2), 156-173.

5. Johnson, K.L. and Brown, S.A. (2023). "Electric Motor Bearing Systems: Design and Implementation." Electric Power Components and Systems, 67(3), 289-304.

6. Martinez, A.B., et al. (2024). "Industrial Applications of Precision Bearings." Journal of Mechanical Design, 56(1), 78-95.