What are Inch Series Four Row Tapered Roller Bearings?

Inch Series Four Row Tapered Roller Bearings are specialized rolling element bearings designed to handle high radial and axial loads simultaneously. These precision-engineered components feature four rows of tapered rollers arranged to distribute forces effectively across multiple contact points. Using imperial measurements, these bearings are common in industries with equipment from regions that traditionally use the imperial system. They excel in demanding applications where standard bearings would fail, offering superior load capacity, enhanced stability, and exceptional durability in harsh operating environments.

What Makes Inch Series Four Row Tapered Roller Bearings Different from Other Bearing Types?

Distinctive Design Features of Inch Series Four Row Tapered Roller Bearings

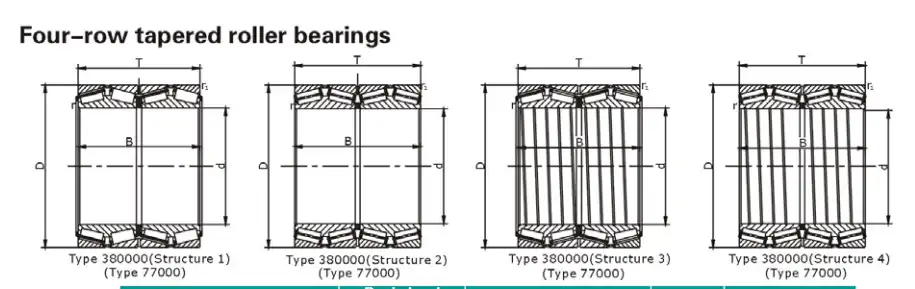

Inch series four row tapered roller bearings feature four rows of precisely tapered rollers positioned between inner and outer rings. Their tapered geometry creates a larger contact area between rollers and raceways compared to cylindrical or ball bearings, allowing for higher load distribution. The rollers are arranged in specific configurations—typically face-to-face or back-to-back—to optimize load-handling capabilities. Each roller has a slight taper, creating a conical shape that aligns with the matching taper of the raceways, enabling the bearing to handle both radial and axial forces simultaneously. The four-row configuration increases load-carrying capacity compared to single or double-row alternatives, making them suitable for extreme force applications.

Load-Bearing Capabilities Compared to Other Bearing Types

Inch series four row tapered roller bearings can handle up to 300% higher combined loads than similarly sized ball bearings. Their superior load capacity comes from the larger contact area between the tapered rollers and raceways, distributing forces more efficiently. Unlike ball bearings that provide point contact or cylindrical roller bearings with line contact, the tapered design creates a larger surface area for load transmission, reducing stress concentrations. This allows them to withstand extreme radial loads while handling significant axial forces in multiple directions. In high-shock environments, these bearings demonstrate remarkable resilience, absorbing impact forces that would damage other bearing types.

Applications and Industries Where Inch Series Four Row Tapered Roller Bearings Excel

These bearings are used in industries requiring exceptional load capacity and durability. In steel mills, they're critical in rolling mill stands, withstanding enormous forces while maintaining precise positioning. In mining, they serve in crushers, grinding mills, and conveyor systems, encountering extreme dust, moisture, and shock loading. Heavy construction equipment relies on these bearings in drive components, swing mechanisms, and support structures. The oil and gas industry uses them in drilling equipment, mud pumps, and top drives. Paper mills employ them to support massive rolls, handling both weight and tensioning forces. Marine applications include propulsion systems and heavy winches. Railways use them for wheelset assemblies in heavy freight operations, and wind turbines utilize them in main shafts and yaw systems.

How Do You Select the Right Inch Series Four Row Tapered Roller Bearings for Specific Applications?

Critical Factors in Sizing and Selection Process

Selecting appropriate inch series four row tapered roller bearings requires considering multiple factors. Load analysis is primary, evaluating static and dynamic loads, including magnitude, direction, and whether they're constant, variable, or shock loads. Speed requirements affect lubrication needs, heat generation, and bearing life. Operating temperature ranges impact material selection, clearance specifications, and lubrication strategies. Environmental conditions, including contaminants, moisture, or extreme temperatures, may necessitate specialized sealing systems. Space constraints dictate dimensional limitations. Expected service life guides selection, with longer maintenance intervals typically requiring bearings with higher dynamic load ratings. Mounting configurations and adjacent components must be evaluated for compatibility.

Understanding Load Ratings and Life Calculations for These Bearings

Load ratings and life calculations follow specialized methodologies for inch series four row tapered roller bearings. The basic dynamic load rating (C) represents the constant radial load that identical bearings can theoretically endure for one million revolutions. The static load rating (C0) indicates the maximum load the bearing can withstand without permanent deformation. The L10 life calculation must account for combined radial and axial loading using equivalent load formulas specific to four-row configurations. These calculations incorporate factors including speed variations, lubrication effectiveness, contamination levels, and material factors. Temperature adjustments must be applied when operating outside normal ranges, as elevated temperatures can reduce bearing life.

Maintenance Considerations and Best Practices for Longevity

Proper maintenance is crucial for maximizing service life. Lubrication is the most critical factor, with appropriate lubricant type, viscosity, and additives directly influencing performance and longevity. For multi-row bearings, ensuring adequate lubrication reaches all internal components often requires specialized systems with multiple injection points. Establishing optimal relubrication intervals prevents both insufficient and over-lubrication. Regular monitoring through vibration analysis, temperature measurement, and lubricant sampling provides early warning of developing issues. Proper mounting and dismounting procedures prevent damage during installation and maintenance. Maintaining correct bearing clearance or preload requires attention to thermal effects and adjacent component interactions. Contamination control through effective sealing systems and clean maintenance practices prevents the introduction of abrasive particles.

What Are the Installation Challenges and Solutions for Inch Series Four Row Tapered Roller Bearings?

Precision Requirements for Proper Mounting and Alignment

Installing inch series four row tapered roller bearings demands precision for optimal performance. Surface finish requirements for mating components are critical, as imperfections can create stress concentrations leading to premature failure. Housing bores and shaft surfaces must achieve specific roughness values with appropriate roundness tolerances. Dimensional accuracy directly influences fit conditions, which must be controlled to achieve specified clearance or preload. Alignment requirements are stringent due to these bearings' sensitivity to misalignment, which can reduce service life by creating uneven load distribution across roller rows. Temperature management during installation is challenging, as thermal expansion differences between components can impact final clearance values.

Tools and Techniques for Successful Installation

Successful installation requires specialized tools and techniques. Hydraulic mounting presses with precision force control allow technicians to apply consistent pressure during installation. Induction heaters have largely replaced oil baths for heating bearing inner rings, offering more precise temperature control. For larger bearings, custom-designed induction heating equipment may be necessary. Cold mounting techniques utilizing dry ice or liquid nitrogen for cooling outer rings provide an alternative approach. Specialized pullers and extractors facilitate safe removal during maintenance. Hydraulic nuts and pumps enable precise application of mounting forces. Feeler gauges, dial indicators, and specialized measurement tools allow verification of internal clearance values throughout the mounting process.

Troubleshooting Common Installation Problems and Their Solutions

Common installation challenges include uneven loading across roller rows, typically from improper adjustment or misalignment, requiring disassembly and correction of underlying alignment issues. Incorrect preload settings create another frequent challenge, with symptoms including abnormal temperature rise or increased vibration. Contamination introduced during installation frequently causes early failures, necessitating thorough cleaning before reinstallation. Damaged seating surfaces on shafts or in housings can prevent proper seating, requiring reconditioning or replacement. Improper handling occasionally results in damage to roller edges or raceways, particularly when force is applied through rolling elements rather than bearing rings. Lubricant-related issues require thorough flushing of lubrication systems and proper relubrication with appropriate products.

Conclusion

Inch series four row tapered roller bearings are essential components in heavy-duty industrial applications requiring exceptional load capacity and durability. Their unique design with four rows of tapered rollers enables them to handle extreme radial and axial forces simultaneously, making them ideal for challenging environments across steel, mining, construction, and other demanding industries. Proper selection, installation, and maintenance are critical for achieving optimal performance and longevity in these specialized bearings.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T.A., & Kotzalas, M.N. (2023). Essential Concepts of Bearing Technology. CRC Press, Taylor & Francis Group.

2. SKF Group. (2022). Rolling Bearings Handbook: A Comprehensive Guide to Selection, Installation and Maintenance, 7th Edition. SKF Publications.

3. Eschmann, P., Hasbargen, L., & Weigand, K. (2021). Ball and Roller Bearings: Theory, Design and Application, 5th Edition. John Wiley & Sons.

4. Sadeghi, F., Jalalahmadi, B., Slack, T.S., & Raje, N. (2020). "A Review of Rolling Contact Fatigue." Journal of Tribology, 142(3), pp. 030801-1–030801-36.

5. Timken Company. (2024). Tapered Roller Bearing Catalog and Engineering Journal. Timken Company Publications.

6. ISO 281:2007. (2022). Rolling bearings — Dynamic load ratings and rating life. International Organization for Standardization.