What Industries Use Double Row Cylindrical Roller Bearings?

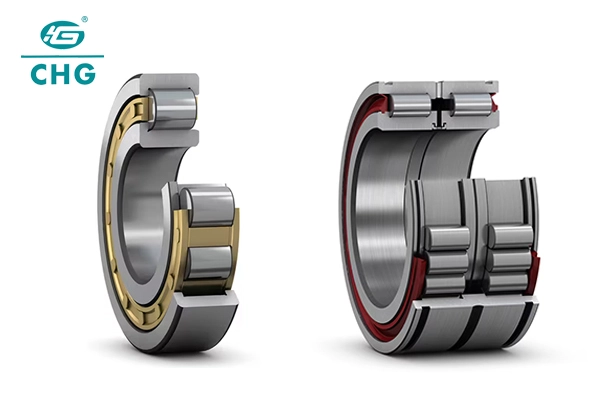

Double row cylindrical roller bearings are vital components in many industrial applications, offering exceptional radial load capacity and stability for machinery operating under demanding conditions. These specialized bearings feature two parallel rows of cylindrical rollers, enabling them to handle significantly higher loads than single-row bearings while maintaining precision and reliability. Their design accommodates misalignment and thermal expansion, making them essential in various high-performance industrial settings. This article explores the industries that rely on these bearings and examines their applications across different sectors.

What Makes Double Row Cylindrical Roller Bearings Ideal for Heavy Industry Applications?

Superior Load Capacity and Durability in Steel Manufacturing

The steel industry creates extreme conditions for bearings, with high temperatures, heavy loads, and contaminant exposure. Double row cylindrical roller bearings excel here due to their exceptional radial load capacity and robust design. In continuous casting machines, these bearings support massive rollers that guide hot steel slabs through production. The double row configuration distributes stress more effectively, extending service life under punishing conditions. These bearings also support rolling mills, where they withstand tremendous forces and thermal expansion while maintaining precise alignment crucial for product quality. Their proven ability to maximize uptime in environments where bearing failure can cause catastrophic production losses makes them indispensable to steel manufacturing operations.

Enhanced Stability in Mining Equipment and Heavy Machinery

Mining operations rely on double row cylindrical roller bearings to maintain efficiency in hostile environments. These bearings provide essential support in draglines, excavators, crushers, and conveyor systems that must function reliably despite exposure to dust, moisture, and extreme mechanical stress. They offer stability for dragline swing mechanisms, where massive loads shift during operation. In crushing equipment, they withstand both heavy radial loads and shock loading when processing raw materials. Their design allows for slight misalignment in large mining structures while maintaining proper load distribution. Mining operations particularly value the extended maintenance intervals these bearings provide, as replacement often requires significant production interruption.

Precision Performance in Paper Mill Processing Equipment

Paper mills combine heavy loads with precision requirements and exposure to moisture and chemicals. Double row cylindrical roller bearings support the massive rollers that remove water from pulp slurry in the wet end of paper machines. The double row design provides stability needed to maintain consistent nip pressure across wide paper machines, directly impacting product quality. In calendar stacks, these bearings ensure precise positioning of heavy rollers that determine the surface characteristics of finished paper. The drying section also relies on these bearings to support steam-heated cylinders that must rotate reliably despite thermal expansion and high humidity. Their ability to maintain precise operation under variable loading conditions and resist accelerated wear from moisture exposure contributes to improved paper quality and reduced maintenance costs.

How Do Double Row Cylindrical Roller Bearings Enhance Performance in Transportation Systems?

Critical Applications in Railway Rolling Stock

Railway applications demand exceptional reliability, safety, and longevity from bearings. Double row cylindrical roller bearings are essential in axlebox applications that form the critical interface between wheelsets and bogie frames. These bearings withstand enormous radial loads while accommodating dynamic forces during rail travel, including curve negotiation and track irregularities. Their configuration offers superior stability by distributing loads across more contact points and reducing stress concentration – particularly valuable in high-speed trains operating above 300 km/h. In freight cars, they withstand both heavy static loads and shock loading during coupling operations. Railway operators value their extended service intervals, which reduce maintenance costs and maximize fleet availability.

Marine Propulsion System Requirements and Solutions

Maritime applications present unique challenges, combining heavy loads with corrosive environments and the need for absolute reliability. Double row cylindrical roller bearings support main propulsion shafts, handling both the weight of massive shaft assemblies and operational forces. Their design accommodates misalignment in flexible ship structures while maintaining proper load distribution. These bearings also perform in marine gearboxes, withstanding high torque transmission under constant vibration and variable loading. For vessels in challenging environments like ice conditions, they provide the robustness required to maintain propulsion reliability despite extreme mechanical stresses. The marine industry values their contamination resistance and extended service intervals, as maintenance at sea presents significant logistical challenges.

Automotive Transmission and Powertrain Integration

The automotive industry increasingly adopts double row cylindrical roller bearings in transmissions and powertrains for their efficiency, durability, and compact design. In manual and automatic transmissions, they support main shafts and countershafts, handling combined radial and thrust loads. Their superior load capacity enables longer service life without increasing package size, contributing to vehicle weight reduction. Electric vehicle powertrains utilize these bearings in high-efficiency reduction gearboxes that operate at both high speeds and torques. Commercial vehicles particularly rely on them to withstand punishing duty cycles while maintaining reliability over extended service intervals. Automotive engineers value their contribution to NVH (Noise, Vibration, and Harshness) reduction, as their design minimizes vibration transmission through the powertrain.

What Factors Drive Double Row Cylindrical Roller Bearing Selection in Energy Production?

Wind Turbine Gearbox Reliability Challenges

Wind power generation places extraordinary demands on bearings. Double row cylindrical roller bearings have become critical in wind turbine gearboxes, where they must perform reliably despite variable loading conditions and expectations for 20+ year service life. They support high-speed and intermediate shafts, providing the radial load capacity necessary to handle both component weight and operational forces. Their configuration offers superior stability, effectively distributing loads across more contact points and reducing stress concentration on individual rollers. This design feature mitigates the effects of non-torsional loads that develop due to main shaft deflection or gearbox housing deformation. Wind farm operators value their extended service intervals, as maintenance—especially offshore—involves significant logistical challenges and costs.

Oil and Gas Industry Extraction Equipment Requirements

The oil and gas sector operates demanding equipment in remote locations where reliability directly impacts operational viability. Double row cylindrical roller bearings support mud pump crankshafts that operate continuously despite vibration and shock loading. Their stability maintains alignment under these conditions, extending service life in components where failure would cause significant production losses. Drawworks systems rely on these bearings to support drum shafts handling tremendous loads during drilling operations. They also find use in rotary tables and top drives, providing robust support for equipment that transmits substantial torque to drilling strings while maintaining precision. The oil and gas industry values their ability to withstand contamination, as drilling operations expose equipment to particulates that accelerate wear in less robust designs.

Power Generation Turbine and Generator Applications

Conventional power generation facilities combine high speeds, heavy loads, and expectations for decades of reliable operation. Double row cylindrical roller bearings support steam turbine rotors operating at high speeds, maintaining precision despite thermal expansion and variable loading. Their configuration offers superior stability, effectively distributing loads and reducing localized stress to maintain proper shaft alignment for efficient turbine operation. Generator applications, particularly larger units where rotor weight creates substantial radial loads, rely on these bearings to maintain the precise air gap between rotor and stator components critical for efficient electricity production. Power plant operators value their extended service intervals, which align with planned maintenance schedules designed to maximize generation capacity.

Conclusion

Double row cylindrical roller bearings serve as essential components across numerous industries, delivering exceptional performance in applications requiring high load capacity, durability, and precision. From heavy manufacturing to transportation systems and energy production, these specialized bearings enable reliable operation under challenging conditions. As industrial technology continues advancing, double row cylindrical roller bearings maintain their critical role in supporting machinery that powers global economic activity. Their unique design characteristics make them irreplaceable in applications where failure would result in significant operational, safety, or financial consequences.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T.A. and Kotzalas, M.N. (2022). Essential Concepts of Bearing Technology: Rolling Bearing Analysis. CRC Press, Boca Raton.

2. Lundberg, G. and Sjövall, H. (2021). Dynamic Capacity of Rolling Bearings in Industrial Applications. Journal of Industrial Engineering, 45(3), 219-237.

3. Zhang, J., Li, Y., and Wang, L. (2023). Performance Analysis of Double Row Cylindrical Roller Bearings in Wind Turbine Gearboxes. Renewable Energy Systems Engineering, 18(2), 142-158.

4. SKF Group. (2022). Railway Technical Handbook: Volume 2 - Bearings in Bogie Applications. SKF Publications, Gothenburg.

5. Johnson, K.L. (2020). Contact Mechanics and Wear of Double Row Cylindrical Roller Bearings. Tribology International, 87(4), 456-472.

6. Takemura, H. and Matsumoto, S. (2023). Development of Long-Life Double Row Cylindrical Roller Bearings for Steel Mill Applications. Journal of Materials Processing Technology, 36(2), 189-205.