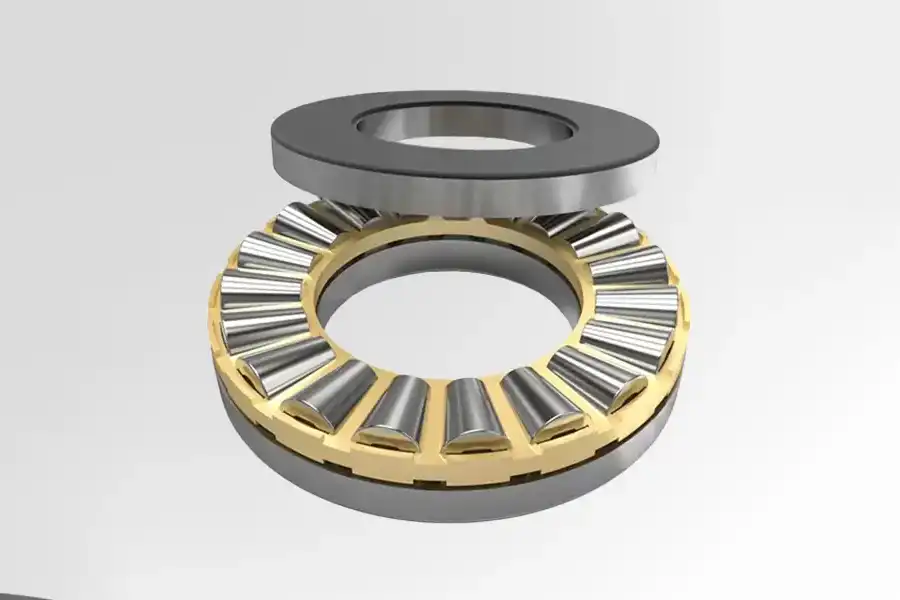

What are the Advantages of Thrust Roller Bearings?

Thrust roller bearings are specialized mechanical components designed to handle axial loads in rotating machinery. These bearings play a crucial role in various industries, from automotive and aerospace to heavy machinery and industrial equipment. The unique design of thrust roller bearings allows them to support heavy loads while minimizing friction and wear, making them an essential component in many high-performance applications. In this blog post, we'll explore the numerous advantages of thrust roller bearings and delve into some frequently asked questions about these vital components.

What are the main applications of thrust roller bearings?

Thrust roller bearings find applications in a wide range of industries and machinery due to their ability to handle high axial loads efficiently. Some of the primary applications include:

1. Automotive industry: In vehicles, thrust roller bearings are commonly used in transmission systems, particularly in the gearbox and clutch assemblies. They help manage the axial forces generated during gear shifts and clutch engagement, ensuring smooth operation and prolonging the life of these critical components. Additionally, thrust roller bearings are utilized in steering columns, where they support the weight of the steering wheel and absorb the forces transmitted through the steering system.

2. Aerospace: The aerospace industry relies heavily on thrust roller bearings for various applications. In aircraft engines, these bearings are used to support the thrust of the turbine and compressor shafts. They play a crucial role in managing the high axial loads generated by the engine's operation, ensuring optimal performance and safety. Thrust roller bearings are also used in landing gear assemblies, where they help absorb the impact forces during takeoff and landing.

3. Industrial machinery: Many types of industrial equipment benefit from the use of thrust roller bearings. In pumps and compressors, these bearings support the axial loads generated by the impeller or rotor, allowing for efficient operation and reduced wear on other components. Machine tools, such as lathes and milling machines, use thrust roller bearings to manage the forces generated during cutting operations, ensuring precision and stability.

4. Wind turbines: The renewable energy sector, particularly wind power, makes extensive use of thrust roller bearings. In wind turbines, these bearings are employed in the main shaft assembly, where they support the weight of the rotor and blades while allowing for smooth rotation. The ability of thrust roller bearings to handle high loads and operate reliably in challenging conditions makes them ideal for this application.

5. Marine propulsion systems: Ships and other marine vessels utilize thrust roller bearings in their propulsion systems. These bearings support the propeller shaft and manage the significant axial forces generated by the propeller's thrust. Their use in this application helps improve efficiency and reduces the wear on other components of the drivetrain.

6. Heavy construction equipment: Excavators, bulldozers, and other heavy machinery often incorporate thrust roller bearings in their design. These bearings are used in the swing mechanisms of excavators, allowing for smooth rotation of the upper structure. They are also employed in the drivetrain components of tracked vehicles, supporting the axial loads generated during operation.

The versatility of thrust roller bearings in handling axial loads across these diverse applications highlights their importance in modern engineering and industry. Their ability to operate efficiently under high loads, at various speeds, and in different environments makes them an indispensable component in many mechanical systems.

How do thrust roller bearings compare to other bearing types in terms of load capacity?

Thrust roller bearings are renowned for their exceptional load-bearing capabilities, particularly when it comes to axial loads. When comparing them to other bearing types, several factors contribute to their superior performance in high-load applications:

1. Contact area and load distribution: Thrust roller bearings feature rollers that provide a larger contact area with the raceways compared to ball bearings. This increased contact area allows for better distribution of the axial load across the bearing surface. As a result, thrust roller bearings can handle significantly higher loads than thrust ball bearings of similar size.

2. Roller geometry: The cylindrical or tapered rollers used in thrust roller bearings are designed to optimize load distribution. Their shape allows for a more even spread of the load along the length of the roller, reducing stress concentrations and increasing overall load capacity. This is in contrast to ball bearings, where the load is concentrated on a smaller point of contact.

3. Stiffness: Thrust roller bearings generally offer higher stiffness compared to other bearing types when subjected to axial loads. This increased stiffness helps maintain proper alignment and reduces deflection under heavy loads, which is crucial in applications requiring high precision or where minimal axial movement is allowed.

4. Load ratings: When comparing the load ratings of different bearing types, thrust roller bearings often outperform others in terms of static and dynamic axial load capacities. For instance, a thrust roller bearing typically has a higher load rating than a thrust ball bearing of the same size, sometimes by a factor of 2 to 3 times or more.

5. Speed limitations: While thrust roller bearings excel in load capacity, it's important to note that they generally have lower speed capabilities compared to ball bearings. This trade-off is often acceptable in applications where high load capacity is the primary requirement, and operating speeds are moderate to low.

6. Friction characteristics: Thrust roller bearings tend to have slightly higher friction compared to ball bearings due to the larger contact area. However, this increased friction is often negligible compared to the benefits of higher load capacity and improved stability under heavy loads.

In summary, thrust roller bearings offer superior load capacity compared to many other bearing types, particularly in applications with high axial loads. Their design features, including larger contact areas, optimized roller geometry, and even load distribution, contribute to their exceptional performance under heavy loads. While they may have some limitations in terms of speed and slightly higher friction, these trade-offs are often outweighed by the benefits of increased load capacity, durability, and stability in demanding applications.

What factors should be considered when selecting a thrust roller bearing for a specific application?

Selecting the appropriate thrust roller bearing for a specific application is crucial to ensure optimal performance, reliability, and longevity of the mechanical system. Several key factors should be carefully considered during the selection process:

1. Load characteristics:

- Axial load capacity: Determine the maximum axial load the bearing will need to support, including both static and dynamic loads. Ensure that the selected bearing's load rating exceeds the maximum expected load with an appropriate safety factor.

- Load direction: Consider whether the load is unidirectional or bidirectional, as this will influence the choice between single-direction and double-direction thrust roller bearings.

- Load variations: Assess if the load is constant or fluctuating, as this may impact the bearing's fatigue life and lubrication requirements.

- Combined loads: Evaluate if there are any radial or moment loads in addition to the primary axial load, as this may necessitate the use of a combined radial-thrust bearing or additional support bearings.

2. Operating speed:

- Rotational speed: Determine the maximum and average operating speeds of the application. Thrust roller bearings have speed limitations, especially under heavy loads, so it's essential to choose a bearing that can handle the required speed range.

- Speed variations: Consider whether the application involves frequent starts and stops or speed changes, as this can affect the bearing's performance and lubrication needs.

3. Environmental conditions:

- Temperature: Assess the operating temperature range, including any temperature fluctuations. This will influence the choice of bearing materials, seals, and lubricants.

- Contamination: Consider the presence of dust, moisture, or other contaminants in the operating environment. This may require the selection of bearings with integrated seals or shields.

- Corrosive environments: If the bearing will be exposed to corrosive substances, consider using bearings made from corrosion-resistant materials or with appropriate surface treatments.

4. Dimensional constraints:

- Available space: Evaluate the space limitations in the application, considering both axial and radial dimensions. This will help determine the appropriate bearing size and type.

- Shaft and housing dimensions: Ensure that the selected bearing is compatible with the existing shaft and housing dimensions, or if modifications are necessary.

5. Precision and stiffness requirements:

- Runout tolerances: Determine the level of axial and radial runout acceptable for the application, as this will influence the choice of bearing precision grade.

- Stiffness needs: Assess whether the application requires high stiffness to maintain precise positioning or to minimize deflection under load.

6. Lubrication:

- Lubrication method: Consider whether the bearing will be grease-lubricated, oil-lubricated, or if it requires a special lubrication system.

- Lubrication intervals: Evaluate the desired maintenance schedule and choose a bearing that aligns with the planned lubrication intervals.

- Operating conditions: Select lubricants that are compatible with the bearing materials and suitable for the operating temperature range and speed.

7. Misalignment tolerance:

- Shaft deflection: Assess whether the application may involve shaft deflection or misalignment between the shaft and housing. In such cases, self-aligning thrust roller bearings might be more suitable.

- Mounting accuracy: Consider the level of precision achievable during installation, as this may influence the choice between rigid and self-aligning bearing designs.

By carefully considering these factors, engineers and designers can select the most appropriate thrust roller bearing for their specific application. This thorough evaluation process helps ensure optimal performance, reliability, and longevity of the mechanical system while minimizing the risk of premature failure or unexpected downtime. It's often beneficial to consult with bearing manufacturers or specialists when dealing with particularly challenging or critical applications, as they can provide valuable insights and recommendations based on their expertise and experience.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. SKF Group. (2021). Thrust roller bearings. SKF.com.

2. Timken Company. (2022). Thrust Bearings. Timken.com.

3. NSK Ltd. (2021). Thrust Roller Bearings. NSK.com.

4. Schaeffler Technologies AG & Co. KG. (2022). Axial cylindrical roller bearings. Schaeffler.com.

5. NTN Corporation. (2021). Thrust Roller Bearings. NTN.com.

6. American Bearing Manufacturers Association. (2022). Roller Bearings. ABMA.com.

7. Machine Design. (2019). What's the Difference Between Bearings? MachineDesign.com.

8. Bearing Tips. (2021). Thrust Bearing Basics. BearingTips.com.

9. Engineering360. (2022). Thrust Bearings Information. GlobalSpec.com

10. Machinery Lubrication. (2020). Understanding Journal, Thrust and Tapered Roller Bearings. MachineryLubrication.com.