What are the Benefits of Using Spherical Roller Bearings in Terms of Service Life?

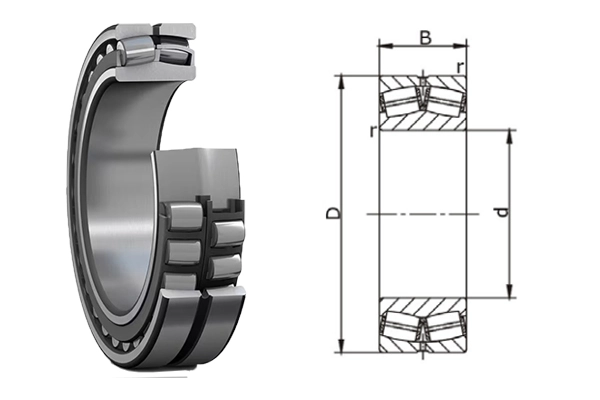

Spherical roller bearings have emerged as a crucial component in modern industrial machinery, offering exceptional durability and reliability in demanding applications. These bearings are engineered with two rows of rollers that operate on a common sphered outer ring raceway, providing unique capabilities for handling heavy radial and axial loads while compensating for misalignment. Their distinctive design contributes significantly to extended service life, making them invaluable in applications where longevity and performance are paramount considerations.

How do operating conditions affect spherical roller bearing performance?

Operating conditions play a fundamental role in determining the performance and longevity of spherical roller bearings. These bearings demonstrate remarkable adaptability across diverse operating environments, primarily due to their self-aligning capabilities and robust design features. In high-temperature environments, spherical roller bearings maintain their structural integrity through specialized heat-treated materials and optimized internal geometries. The bearing's unique design allows for thermal expansion without compromising performance, ensuring consistent operation even under fluctuating temperature conditions.

The self-aligning feature of these bearings proves particularly advantageous in applications where shaft deflection or housing deformation occurs. This capability significantly reduces edge loading and stress concentrations that typically lead to premature bearing failure. In environments with heavy contamination, spherical roller bearings benefit from advanced sealing solutions that effectively prevent the ingress of harmful particles while retaining lubricant. This protection system substantially extends the bearing's operational life by maintaining clean, well-lubricated contact surfaces.

Furthermore, these bearings excel in handling variable load conditions. Their design incorporates optimized roller profiles and cage designs that ensure proper load distribution across the rolling elements. This feature prevents localized stress concentrations and reduces wear patterns that could otherwise shorten bearing life. The bearing's ability to accommodate both radial and axial loads simultaneously makes it particularly valuable in applications where load directions change frequently or unpredictably.

Modern spherical roller bearings also incorporate advanced surface finishing techniques that enhance their performance under boundary lubrication conditions. This improvement is particularly beneficial during start-up periods or in situations where full lubricant films may not be immediately established. The enhanced surface finish reduces friction and wear during these critical operating periods, contributing to extended service life.

What makes spherical roller bearings ideal for heavy-duty industrial applications?

The suitability of spherical roller bearings for heavy-duty industrial applications stems from their exceptional load-carrying capacity and robust design characteristics. These bearings are engineered to handle extreme radial and axial loads while maintaining optimal performance under challenging conditions. The double row of rollers provides superior load distribution capabilities, effectively spreading the load across a larger contact area compared to single-row bearings.

In heavy industrial settings, such as steel mills, mining equipment, or paper machines, spherical roller bearings demonstrate outstanding resistance to shock loads and vibration. The bearing's internal geometry is optimized to maintain proper roller guidance even under severe operating conditions. This design feature prevents roller skewing and reduces the risk of premature failure due to excessive internal forces.

The materials used in manufacturing spherical roller bearings for heavy-duty applications undergo rigorous heat treatment processes to achieve optimal hardness and dimensional stability. This material enhancement ensures consistent performance under high loads and contributes to the bearing's extended service life. Advanced steel grades with improved cleanliness levels reduce the likelihood of subsurface fatigue, a common failure mode in heavily loaded bearings.

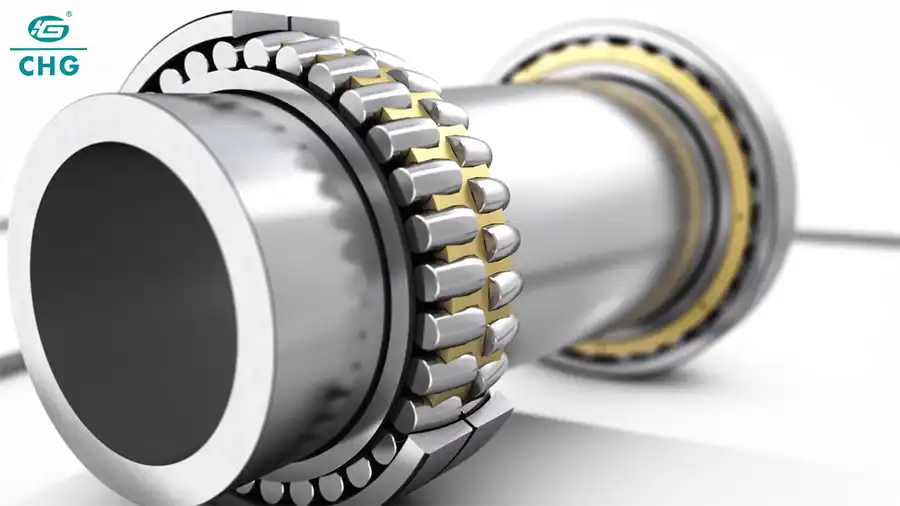

The cage design in modern spherical roller bearings plays a crucial role in their heavy-duty performance. Engineered with materials like brass or steel, these cages provide superior guidance to the rolling elements while withstanding the harsh conditions typical in industrial applications. The cage design also ensures proper lubricant distribution throughout the bearing, contributing to reduced friction and wear.

Additionally, these bearings often incorporate special surface treatments or coatings that enhance their resistance to wear and surface damage. These treatments can significantly extend the bearing's service life in applications where boundary lubrication conditions frequently occur or where contamination is a constant challenge.

How can proper maintenance extend the life of spherical roller bearings?

Proper maintenance strategies play a crucial role in maximizing the service life of spherical roller bearings. A comprehensive maintenance program encompasses several key aspects, including lubrication management, condition monitoring, and proper installation procedures. Regular monitoring and maintenance activities can significantly extend bearing life while preventing unexpected failures and costly downtime.

Lubrication management stands as the cornerstone of effective bearing maintenance. The selection of appropriate lubricants, based on operating conditions and application requirements, directly influences bearing performance and longevity. Modern lubricants formulated specifically for spherical roller bearings contain advanced additive packages that provide enhanced protection against wear, corrosion, and oxidation. Establishing proper relubrication intervals and quantities ensures optimal lubrication conditions throughout the bearing's service life.

Condition monitoring techniques have evolved significantly, offering powerful tools for predictive maintenance. Vibration analysis, temperature monitoring, and oil analysis provide valuable insights into bearing condition and help identify potential issues before they develop into serious problems. Advanced monitoring systems can detect early signs of bearing damage, allowing maintenance teams to plan interventions effectively and prevent catastrophic failures.

Proper installation procedures are equally critical for achieving optimal bearing life. The use of appropriate mounting tools and techniques prevents installation damage that could compromise bearing performance. Careful attention to alignment during installation ensures that the bearing operates within its design parameters, preventing premature wear and extending service life. Regular inspection of mounting arrangements and supporting components helps maintain proper operating conditions throughout the bearing's lifecycle.

Training maintenance personnel in proper handling and installation techniques represents a crucial investment in bearing reliability. Understanding the importance of cleanliness during maintenance procedures and the correct use of mounting tools significantly reduces the risk of contamination and installation-related damage.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. SKF Bearing Maintenance Handbook, 2018 Edition

2. Timken Engineering Manual - Industrial Bearings

3. NSK Technical Report: Advanced Materials in Rolling Bearings

4. Journal of Tribology: "Performance Analysis of Spherical Roller Bearings Under Heavy Loads"

5. Schaeffler Technical Guide: Spherical Roller Bearings in Industrial Applications

6. FAG Rolling Bearings: Fundamentals and Types

7. ASTM International Standard: Testing Methods for Rolling Bearings

8. International Journal of Mechanical Engineering: "Lubrication Systems for Heavy-Duty Bearings"

9. IEEE Transactions on Industrial Applications: "Condition Monitoring of Industrial Bearings"

10. Machine Design Magazine: "Bearing Selection and Maintenance Guidelines for Industrial Equipment"