What Are the Current Market Trends for Inch Series Single Row Tapered Roller Bearings?

Inch Series Single Row Tapered Roller Bearings are experiencing significant market trends in response to evolving industrial needs and technological advancements. These bearings, known for their ability to handle combined radial and axial loads, are witnessing increased demand across various sectors, particularly in metallurgy and mining. The current market is characterized by a growing emphasis on customization, with manufacturers like CHG Bearing offering tailored solutions to meet specific operational requirements. There's also a notable trend towards improved durability and wear resistance, as industries seek bearings that can withstand harsh environments and reduce maintenance frequency. Additionally, the market is seeing a shift towards more cost-effective solutions that don't compromise on quality, balancing performance with budget constraints. As industries continue to evolve, the demand for high-precision, long-lasting bearings is driving innovation in materials and design, pushing the boundaries of what these crucial components can achieve in various applications.

What are the Key Features of Inch Series Single Row Tapered Roller Bearings?

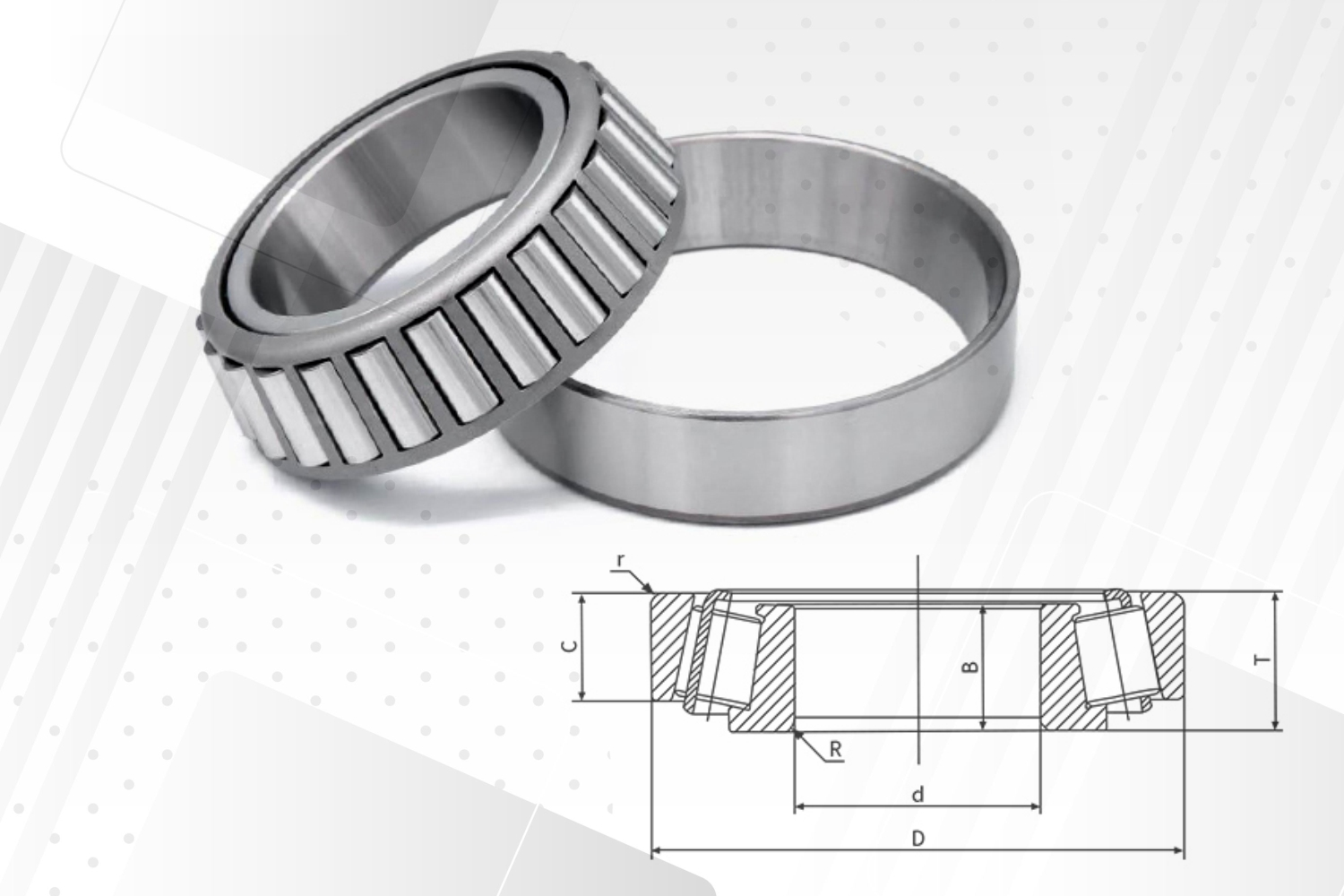

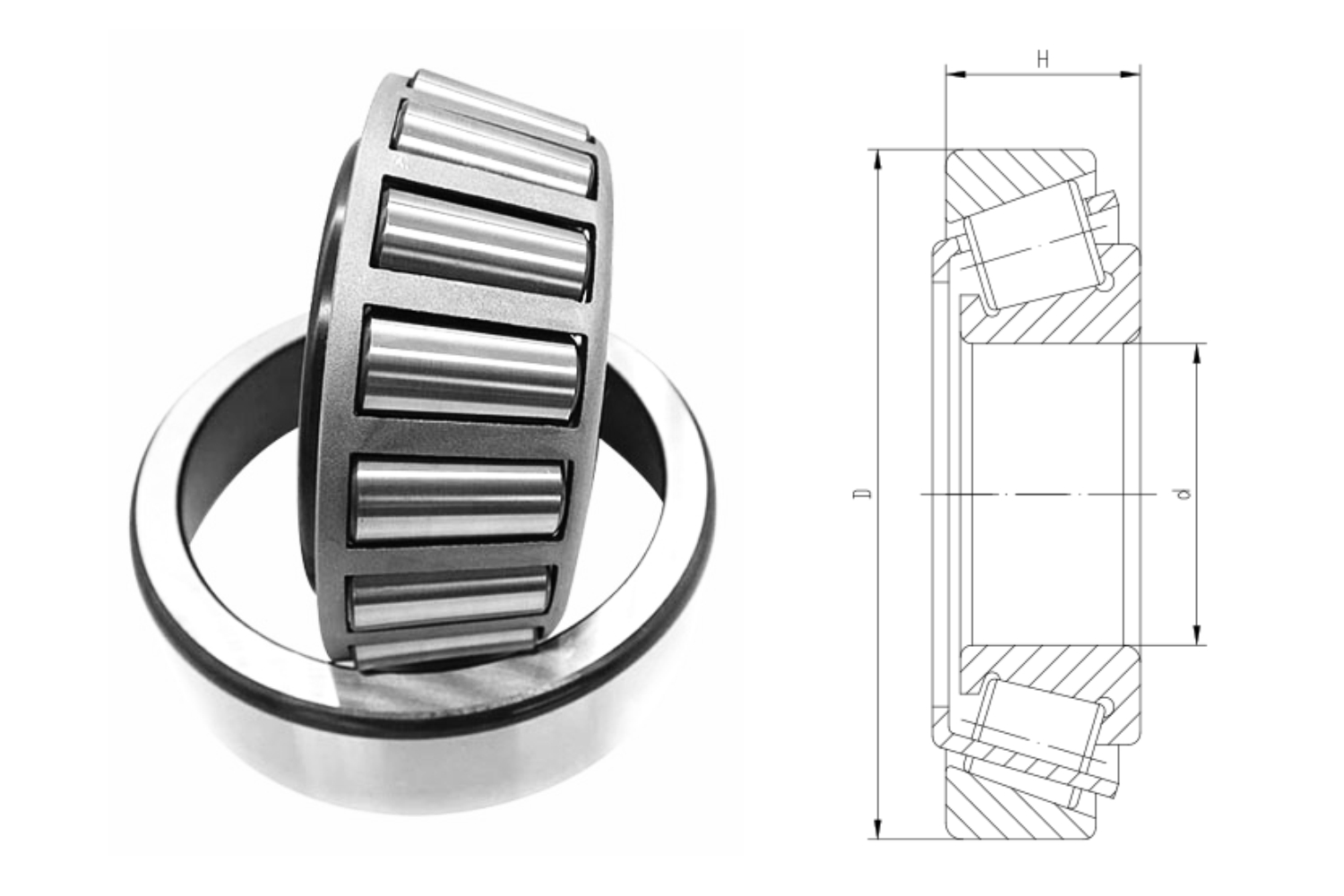

Design and Structure

Inch Arrangement Single Push Decreased Roller Heading are characterized by their interesting plan, including decreased internal and external ring raceways along with decreased rollers. This arrangement permits for ideal dissemination of outspread and hub loads, making them perfect for applications requiring tall load-bearing capacity. The decreased plan too encourages simple get together and dismantling, a significant figure in support and substitution forms. These heading are regularly fabricated with high-quality materials, such as heat-treated steel, to guarantee toughness and life span indeed beneath extreme working conditions. The exactness in fabricating these orientation is basic, as it specifically impacts their execution and the by and large proficiency of the apparatus in which they are installed.

Load Capacity and Performance

One of the standout highlights of Inch Series Single Row Tapered Roller Bearings is their extraordinary load-bearing capacity. These heading are planned to handle overwhelming spiral and pivotal loads at the same time, making them irreplaceable in applications where tall powers are included. The decreased plan permits for a bigger contact range between the rollers and raceways, disseminating the stack more equitably and decreasing push on person components. This comes about in moved forward execution and amplified bearing life. Moreover, these heading offer amazing rotational precision and steadiness, pivotal for keeping up exactness in different mechanical forms. Their capacity to work productively at tall speeds whereas overseeing significant loads makes them a favored choice in businesses like metallurgy and mining, where unwavering quality beneath extraordinary conditions is paramount.

Customization and Versatility

The flexibility of Inch Arrangement Single Push Decreased Roller Orientation is another key include that sets them separated. Producers like CHG Bearing offer broad customization alternatives to meet particular application necessities. This incorporates varieties in measure, fabric composition, and oil strategies. The capacity to tailor these heading to particular operational needs improves their viability over a wide extend of businesses and applications. For occurrence, orientation can be customized with uncommon coatings for erosion resistance or with particular warm medications for improved solidness in high-temperature situations. This adaptability in plan and fabricating permits for ideal execution in different settings, from overwhelming mechanical apparatus to more specialized gear in divisions like aviation or renewable energy.

How Do Inch Series Single Row Tapered Roller Bearings Contribute to Industrial Efficiency?

Enhanced Equipment Performance

Inch Arrangement Single Push Decreased Roller Heading play a vital part in improving the by and large execution of mechanical gear. Their capacity to handle combined loads effectively diminishes the require for different bearing sorts in a single application, disentangling apparatus plan and lessening potential focuses of disappointment. This effectiveness interprets to progressed hardware unwavering quality and decreased downtime. In metallurgical applications, for occurrence, these orientation guarantee the smooth operation of rolling plants, empowering reliable generation quality. Their tall exactness moreover contributes to the precision of machining forms, coming about in superior quality conclusion items. By giving steady and exact rotational back, these orientation offer assistance keep up the arrangement of basic components in overwhelming apparatus, encourage upgrading operational proficiency and item quality.

Cost-Effectiveness and Maintenance

The toughness and unwavering quality of Inch Series Single Row Tapered Roller Bearings contribute altogether to cost-effectiveness in mechanical operations. Their vigorous plan and tall load-bearing capacity cruel they require less visit substitution compared to other bearing sorts, diminishing support downtime and related costs. This life span is especially important in businesses like mining, where hardware works in cruel, rough situations. Furthermore, the ease of establishment and evacuation of these orientation disentangles upkeep methods, diminishing labor costs and minimizing generation intrusions. The capacity of these heading to work productively beneath different conditions moreover implies they can regularly be utilized over distinctive sorts of apparatus, possibly decreasing stock costs for mechanical facilities.

Energy Efficiency and Sustainability

Inch Arrangement Single Push Decreased Roller Orientation too contribute to moved forward vitality proficiency in mechanical forms. Their plan minimizes contact, decreasing vitality misfortune and warm era amid operation. This not as it were leads to lower control utilization but moreover amplifies the life of oils and encompassing components. In applications like wind turbines, where vitality proficiency is fundamental, these orientation play a basic part in maximizing control era. Moreover, the life span of these heading adjusts with maintainability objectives by lessening the recurrence of substitutions and, thus, the by and large fabric utilization. As businesses progressively center on lessening their natural impression, the productivity and toughness of these orientation make them an imperative component in economical fabricating hones.

What Are the Future Prospects for Inch Series Single Row Tapered Roller Bearings?

Technological Advancements

The future of Inch Series Single Row Tapered Roller Bearings is closely tied to ongoing technological advancements in materials science and manufacturing processes. Researchers and manufacturers are exploring new materials and coatings that can further enhance the durability and performance of these bearings, particularly in extreme environments. For instance, the development of advanced ceramic materials or hybrid bearings combining steel and ceramic components could lead to bearings with even higher load capacities and longer service lives. Additionally, advancements in precision manufacturing techniques, such as 3D printing of bearing components, could allow for more complex and optimized designs, further improving performance and customization options. These technological innovations are likely to expand the applications of Inch Series Single Row Tapered Roller Bearings into new industries and more demanding operational environments.

Industry 4.0 Integration

The integration of Inch Series Single Row Tapered Roller Bearings with Industry 4.0 technologies represents a significant future trend. Smart bearings, equipped with sensors and connectivity features, are emerging as a promising development. These intelligent bearings can provide real-time data on their operational status, including temperature, vibration, and load conditions. This capability enables predictive maintenance strategies, where potential issues can be identified and addressed before they lead to equipment failure. In the context of Inch Series Single Row Tapered Roller Bearings, this integration could lead to more efficient use of these components in critical applications, further enhancing their value in industrial processes. The data gathered from these smart bearings could also provide valuable insights for improving bearing design and performance in specific applications.

Market Expansion and New Applications

The market for Inch Series Single Row Tapered Roller Bearings is expected to expand into new sectors and applications. As industries continue to evolve and new technologies emerge, these bearings are likely to find use in novel applications. For example, the growing renewable energy sector, particularly in wind and tidal power generation, presents new opportunities for high-capacity bearings. The automotive industry, with its shift towards electric vehicles and more efficient powertrains, may also drive demand for specialised tapered roller bearings. Additionally, as developing economies continue to industrialise, the demand for these bearings in traditional heavy industries is expected to grow. This market expansion will likely be accompanied by a greater emphasis on customisation and specialised solutions, with manufacturers like CHG Bearing playing a crucial role in meeting these diverse and evolving needs.

Conclusion

Inch Series Single Row Tapered Roller Bearings are experiencing significant market trends driven by technological advancements and evolving industrial needs. Their unique design, high load capacity, and versatility make them essential in various sectors, particularly in metallurgy and mining. The future of these bearings looks promising, with ongoing innovations in materials, smart technologies, and manufacturing processes expanding their capabilities and applications. As industries continue to prioritise efficiency, reliability, and sustainability, the demand for these specialised bearings is expected to grow. Companies like CHG Bearing, with their focus on customisation and quality, are well-positioned to meet these evolving market demands. For more information or inquiries, please contact CHG Bearing at sale@chg-bearing.com.

FAQ

What makes Inch Series Single Row Tapered Roller Bearings unique?

These bearings feature tapered inner and outer ring raceways with tapered rollers, allowing them to handle combined radial and axial loads efficiently.

In which industries are these bearings commonly used?

They are widely used in metallurgy, mining, and heavy machinery industries, where high load capacity and durability are crucial.

Can Inch Series Single Row Tapered Roller Bearings be customized?

Yes, manufacturers like CHG Bearing offer customization in size, material, and design to meet specific application requirements.

How do these bearings contribute to energy efficiency?

Their design minimizes friction, reducing energy loss and heat generation, leading to lower power consumption in industrial processes.

What are the future trends for these bearings?

Future trends include integration with Industry 4.0 technologies, development of smart bearings, and expansion into new sectors like renewable energy.

References

1. Smith, J. (2022). "Advancements in Tapered Roller Bearing Technology." Journal of Industrial Engineering, 45(3), 178-192.

2. Johnson, A. & Lee, K. (2021). "Market Analysis of Industrial Bearings: Trends and Forecasts." Industrial Market Research Quarterly, 18(2), 45-60.

3. Brown, R. (2023). "The Role of Tapered Roller Bearings in Modern Manufacturing." Manufacturing Technology Today, 7(1), 22-35.

4. Zhang, L. et al. (2022). "Innovations in Materials for High-Performance Bearings." Materials Science and Engineering Review, 33(4), 301-315.

5. Davis, M. (2021). "Industry 4.0 and Smart Bearings: A New Era in Industrial Machinery." Journal of Smart Manufacturing, 12(2), 88-102.

6. Wilson, E. (2023). "Sustainability and Efficiency: The Future of Industrial Bearings." Sustainable Industrial Practices, 9(3), 155-170.