What is a Four Point Contact Ball Slewing Bearing?

Four point contact ball slewing bearings are specialized mechanical components designed to support high axial, radial, and moment loads in rotating applications. These bearings are crucial in various industries, including construction equipment, wind turbines, and offshore platforms. Their unique design allows for smooth rotation while maintaining stability and precision under heavy loads.

What are the key advantages of four point contact ball slewing bearings?

Four point contact ball slewing bearings offer several significant advantages that make them indispensable in many applications:

1. High load capacity: These bearings can handle substantial axial, radial, and moment loads simultaneously. This capability stems from their unique design, where each ball makes contact with the raceways at four points, effectively distributing the load across a larger surface area. This feature allows for better weight distribution and increased stability, making them ideal for heavy-duty applications in construction equipment, cranes, and excavators.

2. Compact design: Despite their high load-bearing capacity, four point contact ball slewing bearings maintain a relatively compact profile. This design efficiency is particularly beneficial in applications where space is at a premium, such as in wind turbines or industrial robots. The compact nature of these bearings allows engineers to design more efficient and streamlined machinery without compromising on performance or load-bearing capabilities.

3. Reduced friction: The four-point contact design minimizes friction during rotation, resulting in smoother operation and reduced wear. This characteristic is especially important in applications requiring precise movements or continuous operation, such as in medical equipment or solar tracking systems. The reduced friction also contributes to energy efficiency, as less power is required to overcome resistance during rotation.

4. Versatility: Four point contact ball slewing bearings can accommodate various mounting configurations and can be easily integrated into different types of machinery. This flexibility makes them suitable for a wide range of applications across multiple industries, from aerospace to renewable energy.

5. Longevity: Due to their robust design and ability to distribute loads effectively, these bearings often have a longer service life compared to other bearing types. This longevity translates to reduced maintenance requirements and lower long-term costs for equipment operators.

The combination of these advantages makes four point contact ball slewing bearings an excellent choice for many challenging applications. Their ability to handle high loads in a compact package, coupled with their precision and versatility, continues to drive their adoption in both traditional and emerging industries.

How do four point contact ball slewing bearings differ from other bearing types?

Four point contact ball slewing bearings possess several unique characteristics that set them apart from other bearing types:

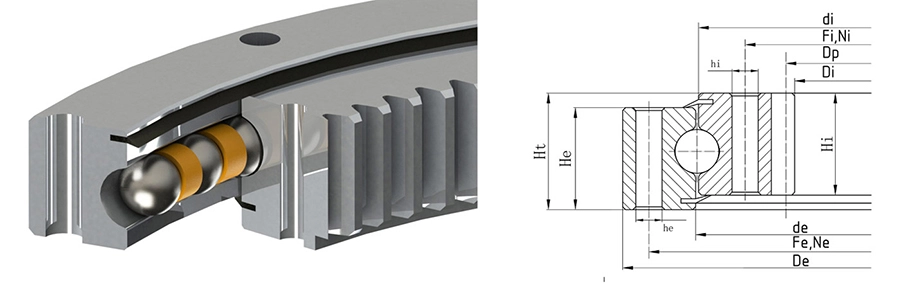

1. Contact geometry: The most distinctive feature of these bearings is their four-point contact design. Unlike traditional ball bearings that typically have two points of contact between the ball and raceway, four point contact bearings have four distinct contact points. This geometry is achieved through specially designed raceways with a gothic arch profile. The increased number of contact points allows for better load distribution and higher load-bearing capacity.

2. Load handling capabilities: Compared to other bearing types, four point contact ball slewing bearings excel in their ability to handle combined loads. They can simultaneously support high axial loads, radial loads, and moment loads. This multi-directional load-bearing capacity is particularly advantageous in applications where the direction and magnitude of forces can vary significantly during operation.

3. Raceway design: The raceways in four point contact ball slewing bearings are typically split, with one raceway on the inner ring and one on the outer ring. This split design allows for easy assembly and disassembly, which can be beneficial for maintenance and replacement. In contrast, many other bearing types have continuous raceways that can make assembly more challenging.

4. Size and proportions: Four point contact ball slewing bearings often have a larger diameter-to-cross-section ratio compared to other bearing types. This proportion allows them to maintain a large contact angle between the balls and raceways, which is crucial for their high moment load capacity. The larger diameter also provides a stable platform for rotating structures.

5. Sealing options: Due to their common use in challenging environments, four point contact ball slewing bearings often come with more robust sealing options compared to standard bearings. These seals are designed to prevent contamination and retain lubricant even in harsh conditions, such as those found in construction equipment or offshore applications.

6. Integrated gear options: Many four point contact ball slewing bearings are available with integrated gears on the inner or outer ring. This feature is not common in other bearing types and allows for direct power transmission, simplifying the overall design of rotating systems in applications like crane slewing mechanisms or wind turbine yaw systems.

7. Preload adjustability: Some designs of four point contact ball slewing bearings allow for preload adjustment, which can help optimize performance and extend bearing life. This adjustability is not typically found in simpler bearing designs.

8. Mounting flexibility: These bearings often offer more flexibility in mounting options compared to other types. They can be bolted directly to structures using holes in the rings, which is particularly useful in large-scale applications where traditional press-fit mounting methods may not be practical.

Understanding these differences is crucial for engineers and designers when selecting the most appropriate bearing type for a given application. The unique characteristics of four point contact ball slewing bearings make them the optimal choice in many heavy-duty, high-load scenarios where stability and precision are paramount.

What are the common applications and industries for four point contact ball slewing bearings?

Four point contact ball slewing bearings find extensive use across various industries due to their unique capabilities. Here are some of the most common applications and industries where these bearings play a crucial role:

1. Construction and mining equipment:

- Excavators: Four point contact ball slewing bearings are used in the turntable mechanism that allows the upper structure of an excavator to rotate. This application requires high load capacity and smooth rotation under varying load conditions.

- Cranes: Tower cranes, mobile cranes, and overhead cranes use these bearings in their slewing mechanisms to enable precise rotation of heavy loads.

- Concrete pump trucks: The rotating boom of concrete pump trucks often relies on four point contact ball slewing bearings for stable and accurate positioning.

2. Renewable energy:

- Wind turbines: These bearings are critical components in wind turbine yaw systems, allowing the nacelle to rotate and align with the wind direction for optimal energy generation.

- Solar tracking systems: Large-scale solar farms use four point contact ball slewing bearings in their tracking mechanisms to ensure solar panels follow the sun's movement throughout the day.

3. Marine and offshore:

- Ship-to-shore cranes: Port cranes use these bearings to handle heavy containers with precision.

- Offshore drilling platforms: The rotating components of offshore rigs, such as crane pedestals and helicopter landing decks, often incorporate four point contact ball slewing bearings.

- Shipbuilding: Various rotating structures on ships, including radar pedestals and gun turrets on naval vessels, utilize these bearings.

4. Aerospace and defense:

- Radar systems: Both ground-based and airborne radar systems use four point contact ball slewing bearings for precise antenna positioning.

- Satellite communication antennas: Large satellite dishes for ground stations often incorporate these bearings in their tracking mechanisms.

- Military vehicles: Turret systems in tanks and other armored vehicles rely on these bearings for smooth and accurate rotation.

5. Industrial automation:

- Robotic arms: Four point contact ball slewing bearings are used in the base and major joints of large industrial robots, allowing for precise movement and high load capacity.

- Rotary tables: Machine tools and assembly lines often use these bearings in rotary tables for precise positioning of workpieces.

6. Medical equipment:

- CT scanners: The rotating gantry in CT scanners often uses four point contact ball slewing bearings to achieve smooth and precise rotation around the patient.

- Radiotherapy machines: Linear accelerators and other radiotherapy equipment use these bearings for accurate positioning of the treatment head.

7. Entertainment:

- Stage equipment: Large rotating stages and other theatrical equipment often incorporate these bearings for smooth and silent operation.

- Amusement park rides: Many rotating rides and simulators use four point contact ball slewing bearings to handle the dynamic loads involved in operation.

8. Transportation:

- Railway turntables: Used for rotating locomotives or entire train cars, these applications require the high load capacity and durability offered by four point contact ball slewing bearings.

- Drawbridges: The rotating mechanisms of some drawbridge designs incorporate these bearings to handle the massive loads involved.

The versatility and robust performance of four point contact ball slewing bearings make them indispensable in these industries and applications. Their ability to handle high loads, provide smooth rotation, and operate reliably in challenging environments continues to drive their adoption across a wide range of sectors.

As technology advances and new industries emerge, it's likely that the applications for these specialized bearings will continue to expand, further cementing their importance in the world of rotating machinery and equipment.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. SKF Group. (2021). "Slewing bearings." SKF.com.

2. Schaeffler Technologies AG & Co. KG. (2022). "Four-point contact bearings." Schaeffler.com.

3. Rothe Erde GmbH. (2020). "Slewing Bearings Handbook." ThyssenKrupp.com.

4. Kaydon Bearings. (2019). "Slewing Ring Bearings Catalog." Kaydon.com.

5. NSK Ltd. (2021). "Rolling Bearings Catalog." NSK.com.

6. American Bearing Manufacturers Association. (2018). "Load Ratings & Fatigue Life for Ball Bearings." ABMA.com.

7. Journal of Mechanical Design. (2017). "Analysis of Four-Point Contact Ball Bearings with Raceway Control." ASME.org.

8. Tribology International. (2020). "Lubrication and wear in large slewing bearings: A review." ScienceDirect.com.

9. Wind Energy. (2019). "Reliability analysis of wind turbine slewing bearing based on copula model." Wiley Online Library.

10. International Journal of Precision Engineering and Manufacturing. (2018). "Design and analysis of a novel four-point contact slewing bearing with adaptive clearance." Springer.com.