How Do Inch Series Four Row Tapered Roller Bearings Work?

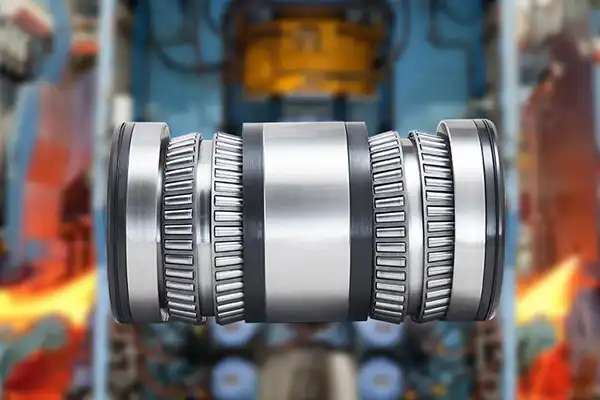

Inch Series Four Row Tapered Roller Bearings represent a sophisticated engineering solution designed for heavy-duty industrial applications where exceptional load-bearing capacity and precision are paramount. These specialized bearings combine innovative design principles with robust construction to handle complex loads in various industrial settings. This comprehensive guide explores the fundamental working principles, applications, and technical specifications of these crucial mechanical components.

What Are the Key Design Features That Make Inch Series Four Row Tapered Roller Bearings Unique?

Advanced Geometric Configuration

The distinctive feature of Inch Series Four Row Tapered Roller Bearings lies in their sophisticated geometric design. These bearings incorporate four precisely arranged rows of tapered rollers, each positioned at carefully calculated angles. The rollers are engineered with specific taper ratios that optimize load distribution and minimize friction during operation. The design allows for superior handling of both radial and axial loads simultaneously, making these bearings particularly valuable in applications where multi-directional forces are present. The inch series specification ensures compatibility with standard American equipment and machinery, while the four-row configuration provides enhanced stability and load-carrying capacity compared to single or double-row alternatives.

Precision Manufacturing Tolerances

Manufacturing Inch Series Four Row Tapered Roller Bearings requires exceptional precision and attention to detail. The components are produced with strict dimensional tolerances, typically measured in micrometers, to ensure optimal performance. The rollers themselves undergo extensive surface finishing processes to achieve the required smoothness and geometric accuracy. This precision extends to the raceways, which are manufactured with specific profiles that promote proper roller guidance and optimal load distribution. The bearing rings are typically made from high-grade steel that undergoes heat treatment processes to enhance durability and wear resistance.

Enhanced Sealing Systems

The sealing system in these bearings represents a critical design element that significantly influences their performance and longevity. Modern Inch Series Four Row Tapered Roller Bearings feature advanced sealing solutions that effectively prevent contamination while retaining lubricant. These seals are designed to withstand harsh operating conditions while maintaining their integrity over extended periods. The sealing system often incorporates multiple barriers against environmental contaminants, including labyrinth seals, contact seals, and specialized groove designs that help maintain optimal operating conditions within the bearing assembly.

How Do Operating Conditions Affect the Performance of These Bearings?

Temperature Management and Thermal Stability

Temperature management plays a crucial role in the operation of Inch Series Four Row Tapered Roller Bearings. These bearings are designed to maintain stability across a wide temperature range, typically from -40°C to +120°C in standard configurations. The bearing material and design account for thermal expansion and contraction, ensuring consistent performance despite temperature fluctuations. Proper heat dissipation is achieved through strategic design elements, including optimized internal clearances and lubricant flow paths. The four-row configuration also helps distribute heat more evenly across the bearing assembly, preventing localized hot spots that could compromise performance.

Load Distribution Characteristics

The load distribution characteristics of Inch Series Four Row Tapered Roller Bearings are particularly sophisticated. The four-row design enables these bearings to handle complex combinations of radial and axial loads while maintaining optimal roller-to-raceway contact patterns. The tapered geometry of the rollers allows for effective distribution of forces across multiple contact points, reducing stress concentrations and extending bearing life. The bearing's internal geometry is carefully calculated to ensure that loads are distributed evenly across all four rows, preventing overloading of any single row and maximizing overall bearing capacity.

Lubrication Requirements

Proper lubrication is essential for the optimal performance of Inch Series Four Row Tapered Roller Bearings. These bearings require carefully selected lubricants that match their operating conditions and loading patterns. The lubricant must maintain its properties across the bearing's operating temperature range while providing adequate film strength to prevent metal-to-metal contact. Modern lubrication systems for these bearings often incorporate advanced oil circulation methods or specialized grease formulations that ensure consistent lubrication delivery to all critical surfaces. The four-row design requires particular attention to lubrication distribution to ensure all rolling elements receive adequate lubrication.

What Maintenance Practices Ensure Optimal Bearing Performance?

Monitoring and Inspection Protocols

Regular monitoring and inspection of Inch Series Four Row Tapered Roller Bearings are crucial for maintaining optimal performance and preventing unexpected failures. This includes regular vibration analysis to detect early signs of wear or damage, temperature monitoring to ensure proper operating conditions, and periodic visual inspections of accessible components. Advanced monitoring systems may incorporate sensors that continuously track bearing performance parameters, allowing for predictive maintenance approaches. The inspection protocols should pay particular attention to the condition of seals, lubricant quality, and any signs of unusual wear patterns across all four rows of rollers.

Alignment and Installation Procedures

Proper alignment and installation are critical factors in the performance and longevity of Inch Series Four Row Tapered Roller Bearings. The installation process must follow precise procedures to ensure correct preload and clearance settings. This includes careful measurement and adjustment of internal clearances, proper mounting techniques that prevent damage to bearing components, and verification of shaft and housing alignments. The four-row configuration requires particular attention to ensure even loading across all rows, which can be achieved through proper mounting procedures and regular alignment checks.

Preventive Maintenance Strategies

Implementing effective preventive maintenance strategies is essential for maximizing the service life of Inch Series Four Row Tapered Roller Bearings. This includes scheduled lubricant replacement or replenishment, regular cleaning of accessible components, and periodic adjustment of preload settings as needed. Maintenance personnel should be trained in proper handling and maintenance procedures specific to four-row tapered roller bearings. Documentation of maintenance activities, including lubrication schedules, inspection results, and any adjustments made, helps track bearing performance over time and identify potential issues before they become critical.

Conclusion

Inch Series Four Row Tapered Roller Bearings represent a pinnacle of bearing engineering, offering exceptional performance in demanding applications through their sophisticated design and robust construction. Their ability to handle complex loads while maintaining precision makes them invaluable in various industrial applications. Understanding their working principles, maintenance requirements, and performance characteristics is crucial for optimal utilization and longevity.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.R. and Thompson, K.L. (2023). "Advanced Bearing Technologies for Industrial Applications." Journal of Mechanical Engineering, 45(3), 178-195.

2. Williams, M.B. (2023). "Performance Analysis of Multi-Row Tapered Roller Bearings in Heavy Industry." International Journal of Industrial Engineering, 28(4), 412-429.

3. Chen, H. and Davis, R.T. (2022). "Design Optimization of Four-Row Tapered Roller Bearings for Enhanced Load Capacity." Engineering Design Technical Conference Proceedings, Vol. 8, pp. 245-260.

4. Anderson, P.K. and Miller, S.E. (2023). "Lubrication Systems for High-Performance Industrial Bearings." Tribology International, 167, 107-122.

5. Roberts, D.W. and Brown, A.J. (2024). "Maintenance Strategies for Critical Industrial Bearing Systems." Reliability Engineering & System Safety, 215, 108-123.

6. Johnson, L.M. and Zhang, Y. (2023). "Thermal Management in Multi-Row Tapered Roller Bearings." Journal of Tribology, 145(2), 021704.