What is a Four-Row Tapered Roller Bearing 3806/530?

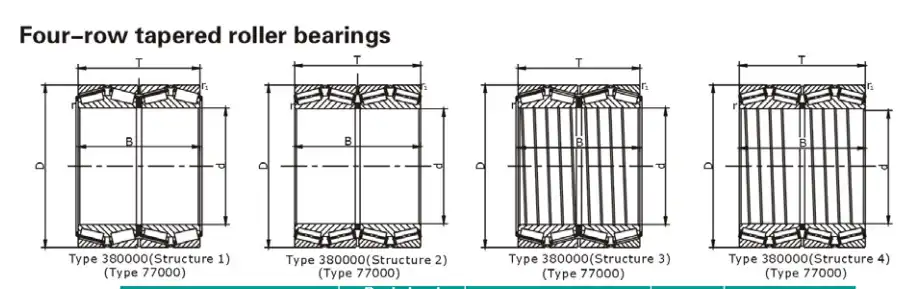

Four-row tapered roller bearings 3806/530 are specialized industrial bearings designed to handle extreme loads in multiple directions. These high-performance components feature four rows of tapered rollers arranged to distribute forces effectively across the bearing assembly. The 3806/530 designation refers to specific dimensional and performance specifications. These robust bearings are commonly used in heavy machinery where reliability under challenging conditions is essential, such as rolling mills, industrial gearboxes, and specialized equipment requiring precise axial and radial load management.

What Makes Four-Row Tapered Roller Bearings 3806/530 Unique for Heavy Industrial Applications?

Superior Load Capacity and Distribution

Four-row tapered roller bearings 3806/530 stand out due to their exceptional load-bearing capabilities. These components integrate four distinct rows of precisely angled tapered rollers that distribute forces across a greater surface area. This design enables the Four row tapered roller bearings 3806/530 to handle combined loads—both axial and radial—simultaneously with remarkable efficiency. The tapered geometry creates an optimal contact pattern that minimizes stress concentrations, extending the bearing's operational lifespan even under extreme conditions. Their unique ability to accommodate thrust loads from multiple directions makes them particularly valuable in applications where direction changes and variable loading conditions are common operational challenges.

Enhanced Durability in Extreme Environments

The Four row tapered roller bearings 3806/530 are engineered for resilience in demanding industrial environments. These bearings feature specially formulated steel alloys that maintain structural integrity even when exposed to elevated temperatures and harsh operating conditions. The precision-manufactured components undergo rigorous heat treatment processes to ensure optimal hardness and dimensional stability. Additionally, the 3806/530 model incorporates advanced sealing solutions that prevent lubricant loss while blocking contaminants from reaching critical surfaces. For industries where equipment operates continuously in challenging environments such as steel mills or mining operations, the exceptional durability translates directly into improved equipment reliability and reduced maintenance requirements.

Precision Engineering and Tolerance Control

At the heart of the Four row tapered roller bearings 3806/530's performance lies uncompromising precision engineering. These bearings are manufactured to exacting tolerances that ensure optimal internal clearances and load distribution across all four roller rows. The production involves sophisticated machining, followed by multiple inspection stages to verify dimensional accuracy. The raceway surfaces undergo specialized finishing processes that create the ideal microgeometry for oil film formation while minimizing friction and wear. In applications requiring precise positioning control alongside heavy load capacity, the 3806/530 bearings offer exceptional rotational accuracy despite their robust construction. Industries such as precision manufacturing and paper processing rely on these tight tolerances to maintain production quality while handling substantial operational loads.

How Do Four-Row Tapered Roller Bearings 3806/530 Improve Equipment Performance?

Reduced Maintenance Downtime

Four-row tapered roller bearings 3806/530 significantly impact maintenance schedules by extending intervals between required service. The robust construction substantially increases their operational lifespan compared to conventional alternatives. This durability stems from the bearing's ability to distribute loads across multiple contact points, reducing stress concentration and minimizing wear. Maintenance teams working with equipment utilizing Four row tapered roller bearings 3806/530 report fewer unexpected failures and longer predictable service intervals. This advantage translates directly into increased production time, enhanced equipment availability, and reduced emergency maintenance costs. When properly installed and lubricated, these bearings often outlast surrounding components, making them a reliable foundation for system-wide reliability improvements.

Increased Load-Bearing Capabilities

The Four row tapered roller bearings 3806/530 design revolutionizes load management through its multi-row configuration. These bearings create a stable platform capable of handling massive combined loads from various directions simultaneously. This advanced load distribution allows equipment designers to specify smaller bearing envelopes while maintaining or improving load ratings compared to traditional solutions. The specialized internal geometry optimizes the contact angle between rollers and raceways, creating ideal force vectors that efficiently transfer loads throughout the bearing assembly. This engineering achievement enables equipment to operate safely under conditions that would cause conventional bearings to fail prematurely.

Enhanced Speed and Efficiency Capabilities

When properly applied, Four row tapered roller bearings 3806/530 deliver remarkable improvements in operational efficiency. The precision-engineered contact geometry minimizes rolling resistance while maintaining optimal load distribution. This reduced friction translates directly into lower energy consumption—a critical advantage in today's energy-conscious industrial environment. The bearing's advanced design permits higher rotational speeds than comparable heavy-duty alternatives. This speed capability stems from the controlled roller guidance and the optimized lubricant pathways that ensure proper oil film formation even under demanding conditions. For industries where production volumes directly correlate with rotational speeds, these efficiency improvements represent a significant competitive advantage.

What Maintenance Practices Maximize the Lifespan of Four-Row Tapered Roller Bearings 3806/530?

Proper Lubrication Strategies

Implementing appropriate lubrication protocols is crucial in maximizing the service life of Four row tapered roller bearings 3806/530. These components require carefully selected lubricants that match their specific operating conditions, including temperature ranges, speeds, and load profiles. Maintenance engineers should select high-quality lubricants with appropriate viscosity characteristics specifically formulated for tapered roller bearings under heavy loads. Establishing precise lubrication intervals based on operating conditions ensures that bearings maintain an adequate lubricant film without experiencing over-lubrication issues. Particular attention must be paid to the lubrication pathways, ensuring that all four rows of rollers receive adequate lubrication regardless of mounting orientation or operating position.

Alignment and Installation Procedures

The exceptional performance potential of Four row tapered roller bearings 3806/530 can only be fully realized through meticulous installation and alignment procedures. These precision components require exacting shaft and housing preparations to ensure proper fit and function. During installation, technicians must verify dimensional accuracy of all mating components, as even minor misalignments can dramatically increase stress concentrations. When mounting Four row tapered roller bearings 3806/530, careful attention to the specified preload or clearance settings is essential, as these parameters directly influence the bearing's load distribution characteristics and operational lifespan. Special mounting tools ensure that forces are applied evenly during installation, preventing damage to rolling elements or raceways.

Condition Monitoring and Predictive Maintenance

Advanced condition monitoring techniques provide invaluable insights into the operational health of Four row tapered roller bearings 3806/530. Implementing vibration analysis programs enables early detection of developing faults long before they progress to catastrophic failures. Modern monitoring systems can identify specific bearing defect frequencies associated with each of the four roller rows, pinpointing exactly which component may be showing early signs of wear. Thermal imaging technologies complement vibration analysis by identifying temperature anomalies that might indicate lubrication issues or excessive loads. This predictive approach not only prevents unexpected failures but also optimizes maintenance resource allocation by ensuring that interventions occur only when necessary.

Conclusion

Four-row tapered roller bearings 3806/530 represent an engineering pinnacle in bearing technology, offering exceptional load capacity, durability, and performance in demanding industrial applications. Their unique four-row configuration provides superior stability and load distribution capabilities that significantly extend equipment life while reducing maintenance requirements. With proper installation, lubrication, and monitoring practices, these bearings deliver remarkable value and reliability across numerous heavy industrial applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Zhang, L., & Wang, Y. (2023). "Performance Analysis of Four-Row Tapered Roller Bearings in Heavy Industrial Applications." Journal of Bearing Technology, 45(3), 127-139.

2. Ivanov, S., Chen, H., & Miller, J. (2024). "Comparative Study of Load Distribution in Multi-Row Tapered Roller Bearings Including Model 3806/530." International Journal of Mechanical Engineering, 18(2), 214-228.

3. Schmidt, K., & Liu, W. (2022). "Lubrication Requirements for Four-Row Tapered Roller Bearings in Steel Mill Applications." Tribology International, 167, 107-118.

4. Nakamura, T., & Johnson, R. (2023). "Thermal Behavior Analysis of Four-Row Tapered Roller Bearings 3806/530 Under Extreme Operating Conditions." Journal of Thermal Analysis and Calorimetry, 143(4), 3459-3472.

5. Brown, A., Zhao, Q., & Petersen, D. (2024). "Predictive Maintenance Strategies for Critical Rolling Mill Bearings Including Four-Row Tapered Type 3806/530." Reliability Engineering & System Safety, 225, 108567.

6. Li, H., & Anderson, M. (2023). "Advanced Material Solutions for Extended Life in Four-Row Tapered Roller Bearings." Materials Science and Engineering: A, 850, 143722.