What is a Type C Thin Section Bearing?

Type C thin section bearings are specialized precision components designed for applications requiring minimal space and high accuracy. These bearings belong to the family of thin section bearings but are specifically characterized by their unique contact angle and load-bearing capabilities. With their slim profile and exceptional performance characteristics, Type C bearings have become indispensable in various industrial and precision engineering applications. They represent a significant advancement in bearing technology, combining innovative design principles with modern manufacturing techniques to deliver superior performance in compact packages.

How Do Type C Thin Section Bearings Differ from Other Bearing Types?

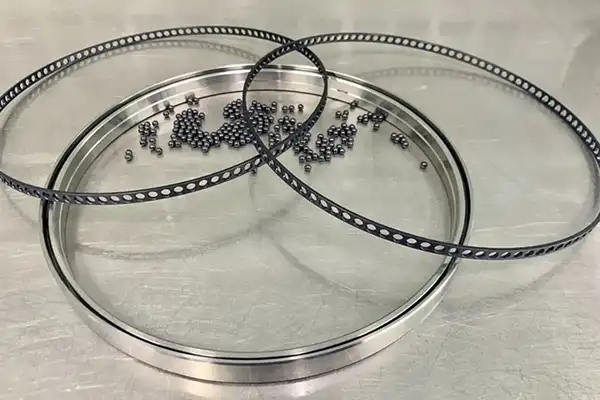

Type C thin section bearings stand apart from other bearing types through several distinctive features. Their most notable characteristic is the specialized contact angle, typically around 15 degrees, which provides an optimal balance between radial and axial load capacity. This design enables them to handle combined loads effectively while maintaining their compact profile. The bearing's cross-section remains constant regardless of the diameter, making them particularly valuable in applications where weight reduction is crucial.

The manufacturing process of Type C bearings involves precision engineering to maintain extremely tight tolerances. The raceways are ground to exceptional smoothness, often achieving surface finishes of less than 0.1 micrometers. This superior finish contributes to reduced friction and enhanced operational smoothness. The balls are typically made from high-grade chrome steel or ceramic materials, carefully selected to match the application requirements. These bearings also feature optimized internal geometry, with the ball complement and cage design specifically engineered to maximize performance while minimizing friction and heat generation.

In comparison to traditional bearings, Type C thin section bearings offer significantly reduced weight without compromising strength. Their unique design allows for larger ball sizes relative to the bearing cross-section, resulting in higher load-carrying capacity despite their slim profile. This characteristic makes them particularly suitable for applications in aerospace, medical equipment, and precision instruments where space and weight constraints are critical considerations.

The internal clearance of Type C bearings is precisely controlled during manufacturing, ensuring optimal performance across a wide temperature range. The cage design incorporates advanced materials and geometries to provide stable ball guidance while minimizing friction and wear. Advanced surface treatments and coatings can be applied to enhance durability and reduce friction further, particularly in challenging operating environments.

What Are the Primary Applications and Benefits of Type C Thin Section Bearings?

Type C thin section bearings find extensive applications across various industries due to their versatile performance characteristics. In robotics and automation, these bearings are crucial components in robotic arms and precision positioning systems, where their ability to maintain accuracy under varying loads is essential. The medical industry relies on Type C bearings for imaging equipment like CT scanners and MRI machines, where smooth operation and precise movement are paramount.

The aerospace sector represents another significant application area, utilizing these bearings in satellite positioning systems, antenna gimbals, and various flight control mechanisms. Their low weight and high precision make them ideal for these demanding applications. In semiconductor manufacturing equipment, Type C bearings are essential components in wafer handling systems and precision positioning stages, where minimal friction and high accuracy are critical requirements.

The benefits of Type C thin section bearings extend beyond their space-saving design. Their low starting torque and consistent running torque contribute to improved energy efficiency in various applications. The bearings' ability to operate at high speeds while maintaining precision makes them valuable in high-performance machinery. Additionally, their design allows for excellent heat dissipation, which helps extend operational life and maintain reliability under continuous use.

These bearings excel in applications requiring high rotational accuracy and smooth operation. Their design enables them to maintain precise positioning even under varying load conditions, making them ideal for optical equipment and precision measurement devices. The combination of high stiffness and low friction characteristics allows for exceptional positioning accuracy, often achieving angular accuracies of less than one arc-second.

What Maintenance and Installation Considerations Are Important for Type C Thin Section Bearings?

Proper maintenance and installation of Type C thin section bearings are crucial for optimal performance and longevity. The installation process requires careful attention to alignment and mounting surface preparation. The bearing housing must be machined to precise tolerances to ensure proper fit and prevent distortion of the bearing rings. Proper handling during installation is essential, as these precision components are sensitive to contamination and physical damage.

Maintenance protocols for Type C bearings typically include regular monitoring of operating conditions such as temperature, vibration, and noise levels. Lubrication management is particularly critical, with the choice of lubricant and relubrication intervals depending on specific application requirements. Modern condition monitoring systems can be employed to track bearing performance and predict maintenance needs, helping prevent unexpected failures and optimize maintenance schedules.

Installation considerations must also account for thermal expansion and operating environment conditions. Proper preload adjustment is crucial for optimal performance, as incorrect preload can lead to premature failure or reduced accuracy. The mounting system should accommodate thermal expansion while maintaining proper bearing alignment. Environmental protection measures, such as sealing systems, must be carefully selected to prevent contamination while minimizing friction increase.

The success of Type C bearing installations often depends on the precise control of mounting tolerances and surface finishes. Housing bore roundness and cylindricity must be carefully controlled to prevent bearing distortion. The selection of appropriate mounting fits requires consideration of operating conditions, including temperature variations and load patterns. Advanced mounting techniques, such as heat mounting or hydraulic mounting, may be employed for larger bearing sizes to ensure proper installation without damage.

Maintenance strategies should include regular inspection of sealing effectiveness and lubricant condition. Contamination control is particularly critical for these precision bearings, as even small particles can significantly impact performance and life. The development of comprehensive maintenance schedules should consider factors such as operating environment, load conditions, and speed requirements. Training of maintenance personnel in proper handling and installation techniques is essential for maintaining optimal bearing performance.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. Journal of Tribology International, "Advanced Bearing Technology in Precision Applications" (2023)

2. Mechanical Engineering Handbook, "Thin Section Bearings: Design and Applications" (2022)

3. SKF Technical Publication, "Precision Bearing Selection Guide" (2023)

4. NSK Americas, "Thin Section Bearing Technology Guide" (2024)

5. Timken Engineering Manual, "Precision Bearing Applications" (2023)

6. Journal of Mechanical Design, "Evolution of Thin Section Bearing Technology" (2022)

7. American Bearing Manufacturers Association, "Technical Standards for Precision Bearings" (2023)

8. IEEE Robotics and Automation Letters, "Bearing Technologies in Modern Robotics" (2023)

9. Aerospace Engineering Journal, "Critical Components in Satellite Systems" (2024)

10. Manufacturing Technology Quarterly, "Precision Bearings in Industrial Applications" (2023)