Crb Bearing

Generally, a single-row cylindrical roller ring consists of four major components as follows:

inner ring, outer ring, rollers, and cage.

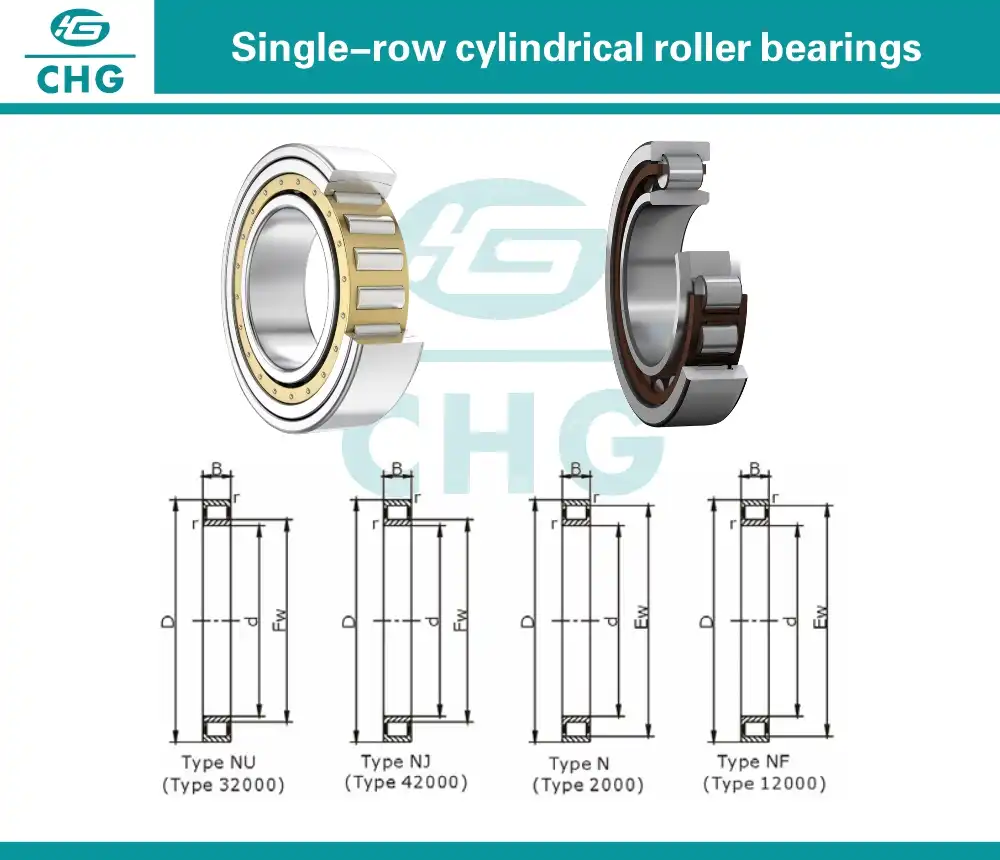

2. Series Type: NU, NJ, N, NF series cylindrical roller bearing.

3. Advantages:The single-row cylindrical roller bearing is one separable type bearing. Generally, a single-row cylindrical roller ring consists of four major components as follows: inner ring, outer ring, rollers, and cage. The rollers are typically guided by two ribs of bearing ring .

This kind of bearing is easy to assemble,disassemble and applicable for high-speed rotation cases. So, compared with a normal radial ball bearing with same size, the cylindrical roller bearing is more suitable to the condition which require to bear higher radial load and higher impact resistance.

Normally,it is not used to bear an axial load. It is required the angle between the axes of its inner and outer rings is slight, generally less than 4'. Profiling of the rollers and the raceway generatrix can reduce the inclination requirement somewhat.

We manufacture single row cylindrical roller bearings are available in several designs. The main difference is the configuration of the flanges. The most popular designs are N design bearing,NU design bearing ,NJ design bearing,NUP design bearing.

4. Size range: Inter diameter:120-1320mm

5. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

CRB Bearing, or cylindrical roller bearings, are critical components designed to handle high radial loads with minimal friction. Their design enables them to support heavy loads while maintaining smooth operation, making them indispensable in various industries, particularly in metallurgy and mining. These bearings are known for their precision, durability, and efficiency, which makes them a preferred choice for demanding applications.

CHG Bearing: Your Trusted Crb Bearing Manufacturer

At CHG Bearing, we pride ourselves on being a leading manufacturer and supplier of Crb Bearing, equipped to meet the diverse needs of the metallurgical and mining industries. With over 30 years of experience in the industry, we have established a reputation for delivering high-quality bearings tailored to specific operational requirements.

Why Choose CHG Bearing?

- Customization and Solutions: We offer customized the products designed for different working conditions, ensuring optimal performance for your equipment.

- Proven Expertise: Our extensive experience includes collaborations with numerous large companies, underscoring our reliability and expertise.

- Innovative Design: With over 50 invention patents, our bearings represent cutting-edge technology. Our commitment to quality is reflected in our ISO9001 quality management and ISO14001 environmental management certifications.

For more information or to discuss your specific needs, please contact us at sale@chg-bearing.com.

Technical Specifications

| Specification | Details |

|---|---|

| Type | Cylindrical Roller Bearing |

| Material | High-Grade Steel |

| Precision | P0, P6, P5, P4 |

| Load Capacity | High Radial Load Capacity |

| Operating Temp | Up to 150°C |

| Lubrication | Grease, Oil |

Crb Bearing Benefits

- High Load Capacity: Capable of handling substantial radial loads, the products ensure stable and reliable equipment operation.

- Reduced Friction: Their design minimizes friction, enhancing efficiency and reducing energy consumption.

- Durability: Built to withstand harsh conditions, including high temperatures and heavy loads, extending the service life of your equipment.

- Precision Engineering: Offers precise performance and smooth operation, crucial for high-speed and high-load applications.

Applications

Crb Bearing is widely used in various applications, including:

- Metallurgical Equipment: Blast furnaces, rolling mills, and steelmaking machinery.

- Mining Machinery: Jaw crushers, impact crushers, vibrating screens, and feeders.

- Heavy Machinery: Equipment requiring robust support for rotation and load-bearing, such as large rotating assemblies.

Installation Guide

- Preparation: Ensure the bearing housing and shaft are clean and free of debris.

- Alignment: Properly align the bearing to avoid uneven load distribution.

- Mounting: Use appropriate tools to mount the bearing, applying uniform pressure to avoid damage.

- Lubrication: Apply the recommended lubricant to ensure smooth operation and longevity.

Maintenance and Care

To ensure the longevity and optimal performance of Crb Bearing:

- Regular Inspection: Check for signs of wear, noise, or vibration.

- Lubrication: Keep bearings adequately lubricated as per manufacturer recommendations.

- Cleaning: Periodically clean the bearings and surrounding areas to prevent contamination.

- Temperature Monitoring: Monitor operating temperatures to prevent overheating and potential damage.

FAQ

Q: What are the main benefits of this Bearings?

A: The products offer high load capacity, reduced friction, enhanced durability, and precision engineering.

Q: How do I know if this Bearings are suitable for my equipment?

A: Assess your equipment’s load, speed, and operating conditions to determine if the products meet your requirements.

Q: What is the recommended maintenance routine for Crb Bearings?

A: Regular inspections, proper lubrication, and cleanliness are essential for maintaining the products.

Q: Can CHG Bearing provide custom solutions?

A: Yes, we offer customized products tailored to specific operational needs.

Customer Reviews

"CHG Bearing has been our go-to supplier for it. Their products are top-notch, and their customer service is exceptional." - John Doe, Production Manager

"We’ve been impressed with the durability and performance of the products from CHG. Their quick delivery and support are commendable." - Jane Smith, Purchasing Manager

Contact Us

For inquiries or to place an order, feel free to reach out to us:

Email: sale@chg-bearing.com

Website: www.chg-bearing.com