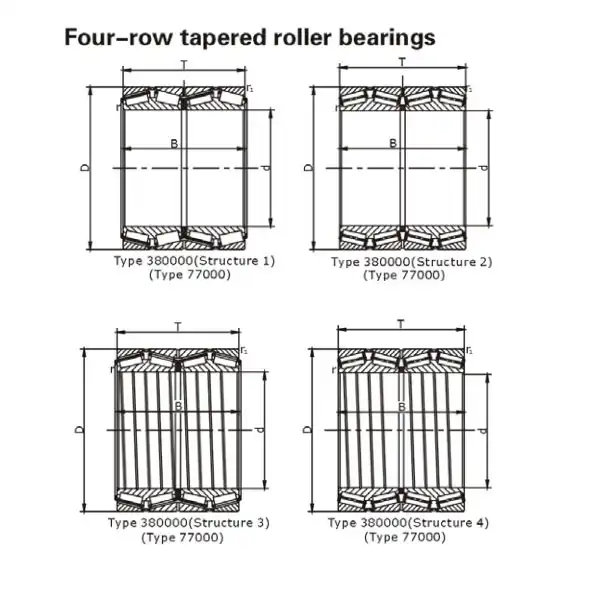

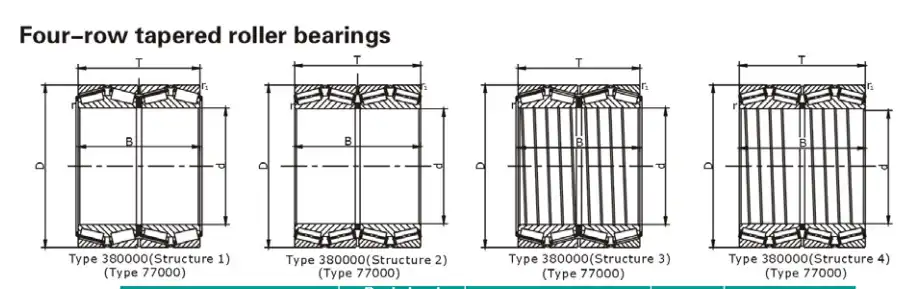

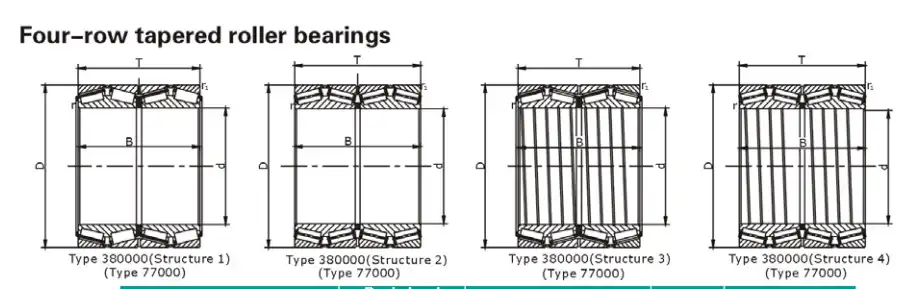

Four Row Tapered Roller Bearing

2. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

3.Features: Four row tapered roller bearings are the one kind of roll neck bearings, their radial and axial loading capacity are high, can carry heavy axail loads in two directions, and their radial loading capacity is 3 times heavier than single row tapered roller bearings.

4. Application: Four row tapered roller bearings mainly used in the working roll necks of hot or cold rolling mills, and roll neck of cogging mills. They usually clearance fit with roll necks to being mounted and dismounted conveniently.

5. Cage: Steel pressed cages are usually used in four row tapered roller bearings, and pin type cages are for large size taper bearings.

6. Advantage: We supplies many sizes of four row tapered roller bearings with integral radial shaft seals at both sides. They are available in several designs depending on bearing size as well as on the open (non-sealed) basic design.

What is a Four Row Tapered Roller Bearing?

A Four Row Tapered Roller Bearing is a precision-engineered component designed to handle high radial and axial loads. Unlike standard bearings, it features four rows of tapered rollers arranged in a way that allows for superior load distribution and reduced friction. This design enhances the bearing’s performance in demanding applications, making it ideal for heavy machinery and large-scale industrial equipment.

Why Choose CHG Bearing?

At CHG Bearing, we pride ourselves on being a leading manufacturer and supplier of the products. Our extensive experience and commitment to quality set us apart in the industry. Here’s why you should consider us for your bearing needs:

Industry Expertise: With over 30 years of experience in the bearing industry, we have built a reputation for reliability and excellence. We’ve collaborated with numerous large companies, ensuring that our products meet the highest standards.

Certifications and Patents: Our company holds more than 50 invention patents and has achieved certifications such as ISO9001 (Quality Management System) and ISO14001 (Environmental Management System). These accolades reflect our dedication to quality and innovation.

For more information or to discuss your specific needs, contact us at sale@chg-bearing.com.

Technical Specifications

| Feature | Specification |

|---|---|

| Type | Four Row Tapered Roller Bearing |

| Load Rating | High radial and axial loads |

| Material | GCr15, G20Cr2Ni4A or customized materials |

| Precision Class | P0, P6, P5, P4 |

| Operating Temperature Range | -20°C to +150°C |

| Lubrication | Grease or oil lubrication |

| Customization | Size, structure, and material options available |

Benefits of Four Row Tapered Roller Bearings

Enhanced Load Capacity: Capable of supporting high radial and axial loads, making them suitable for heavy-duty applications.

Improved Durability: Designed to withstand harsh operating conditions, including high temperatures and heavy loads, resulting in a longer service life.

Reduced Friction: The tapered roller design minimizes friction, leading to smoother operation and increased efficiency.

Customization Options: Adaptable to various requirements and working conditions, ensuring optimal performance for specific applications.

Production process

Applications

Four Row Tapered Roller Bearing is commonly used in industries where heavy loads and demanding conditions are prevalent, including:

- Metallurgical Equipment: Blast furnaces, rolling mills, and steelmaking machinery.

- Mining Machinery: Jaw crushers, impact crushers, vibrating screens, and feeders.

- Large Rotating Equipment: Essential for machinery that requires robust support and high load capacity.

Installation Guide

Preparation: Ensure that the bearing and housing are clean and free from contaminants.

Alignment: Properly align the bearing with the housing to avoid misalignment issues.

Fitting: Carefully press the bearing into place using appropriate tools. Avoid excessive force that could damage the bearing or housing.

Lubrication: Apply the recommended lubricant to ensure smooth operation and longevity.

Maintenance and Care

Regular Inspections: Check for signs of wear, damage, or lubrication issues periodically.

Lubrication: Maintain proper lubrication to reduce friction and prevent premature wear.

Cleaning: Keep the bearing and surrounding areas clean to prevent contaminants from affecting performance.

Replacement: Replace bearings as needed to avoid equipment failure and maintain operational efficiency.

FAQ

Q: What makes Four Row Tapered Roller Bearings different from other types?

A: The products provide superior load capacity and durability compared to standard bearings due to their design with four rows of rollers.

Q: Can I customize the products?

A: Yes, we offer customization options to meet specific requirements, including size, material, and lubrication method.

Q: How do I know if a Four Row Tapered Roller Bearing is right for my application?

A: Consider the load capacity, operating conditions, and size requirements of your equipment. Consult with our experts for personalized recommendations.

Customer Reviews

"The Four Row Tapered Roller Bearing from CHG Bearing has significantly improved the performance and reliability of our equipment. The customization options and quick response have been invaluable to our operations."

— Production Manager, Steel Manufacturing Plant

"Excellent quality and service! The bearings exceeded our expectations in terms of durability and load capacity. Highly recommend CHG Bearing for any heavy-duty applications."

— Technical Engineer, Mining Equipment Manufacturer

Contact Us

For further information, quotes, or assistance with your bearing needs, please reach out to us via Email at sale@chg-bearing.com. We look forward to supporting your bearing requirements with our high-quality products and services.

| Boundary dimensions | Basic load ratings | Part number | Mass | Limiting speeds | |||||||

| mm | kN | Current | Original | kg | r/min | ||||||

| d | D | T | rmin | r1min | Cr | Cor | Grease | Oil | |||

| 150 | 210 | 165 | 2.5 | 2 | 700 | 1700 | 382930 | 2077930 | 16.5 | 670 | 850 |

| 212 | 155 | 3 | 2.5 | 964 | 2350 | 30630 | - | 16.8 | 670 | 850 | |

| 160 | 220 | 165 | 2.5 | 2 | 795 | 2090 | 382932 | 2077932 | 18.5 | 670 | 850 |

| 265 | 173 | 3 | 2.5 | 1450 | 2760 | 380632 | - | 35.7 | 670 | 850 | |

| 170 | 240 | 175 | 3 | 2.5 | 1210 | 3000 | 380634 | - | 24.2 | 670 | 850 |

| 260 | 230 | 3 | 2.5 | 907 | 1720 | 382034 | 2077134 | 39.5 | 670 | 850 | |

| 180 | 250 | 185 | 2.5 | 2 | 1280 | 3400 | 382936 | - | 27.5 | 670 | 850 |

| 260 | 160 | 2.5 | 2 | 1140 | 2550 | 380636 | - | 26.7 | 670 | 850 | |

| 200 | 282 | 206 | 3 | 2.5 | 1680 | 2510 | 380640 | - | 42.1 | 560 | 700 |

| 310 | 200 | 3 | 2.5 | 1660 | 3100 | 382040X2 | 2077140 | 55.6 | 560 | 700 | |

| 310 | 275 | 3 | 2.5 | 1760 | 4200 | 382040 | 2077140 | 75.1 | 560 | 700 | |

| 205 | 320 | 205 | 3 | 3 | 1590 | 3260 | 380641 | 77741 | 57 | 500 | 630 |

| 220 | 340 | 305 | 4 | 3 | 2070 | 5430 | 382044 | 2077144 | 97.9 | 500 | 630 |

| 225 | 320 | 230 | 2.5 | 2 | 1910 | 5000 | 380645 | 77745 | 58 | 500 | 630 |

| 230 | 315 | 190 | 2.5 | 2 | 1600 | 4310 | 380646 | 77746 | 42.5 | 500 | 630 |

| 240 | 360 | 310 | 4 | 3 | 2110 | 5610 | 382048 | 2077148 | 90.5 | 450 | 560 |

| 250 | 385 | 255 | 5 | 4 | 2870 | 6450 | 381050 | 77150 | 107 | 380 | 480 |

| 260 | 360 | 265 | 3 | 2.5 | 1760 | 5220 | 382952 | 2077952 | 76.3 | 450 | 560 |

| 400 | 255 | 4 | 7.5 | 2300 | 5000 | 380652 | 77752 | 114 | 490 | 600 | |

| 400 | 345 | 5 | 4 | 2960 | 7380 | 382052 | 2077152 | 153 | 430 | 530 | |

| 440 | 300 | 2 | 5 | 3550 | 8200 | 380152 | 777752 | 164 | 450 | 560 | |

| 280 | 395 | 288 | 5 | 5 | 3051 | 8320 | 380656 | - | 108 | 450 | 560 |

| 420 | 250 | 5 | 5 | 2780 | 5700 | 380656X2 | 77756 | 119 | 450 | 560 | |

| 460 | 324 | 5 | 4 | 2840 | 7290 | 381156 | 1077756 | 200 | 360 | 450 | |

| 300 | 420 | 300 | 4 | 3 | 2330 | 7210 | 382960 | 2077960 | 130 | 380 | 480 |

| 420 | 310 | 4 | 3 | 3250 | 8150 | 380660 | 77860 | 134 | 380 | 480 | |

| 460 | 390 | 5 | 4 | 3180 | 9330 | 382060 | 2077160 | 238 | 360 | 450 | |

| 500 | 350 | 5 | 4 | 2980 | 6950 | 381160X2 | 77760 | 286 | 340 | 430 | |

| 500 | 370 | 5 | 4 | 3390 | 8710 | 381160 | 1077760 | 285 | 340 | 430 | |

| 320 | 460 | 338 | 4 | 4 | 2950 | 8200 | 380664 | 77764 | 180 | 360 | 450 |

| 460 | 380 | 4 | 4 | 3100 | 8750 | 380664X2 | 77864 | 218 | 360 | 450 | |

| 480 | 390 | 5 | 4 | 3180 | 9330 | 382064 | 2077164 | 234 | 340 | 430 | |

| 540 | 364 | 5 | 5 | 6330 | 14400 | 381164X2 | - | 347 | 340 | 430 | |

| 340 | 460 | 310 | 4 | 3 | 2480 | 8100 | 382968 | 2077968 | 145 | 340 | 430 |

| 480 | 350 | 5 | 5 | 4400 | 12600 | 380668 | - | 195 | 320 | 400 | |

| 520 | 325 | 5 | 4 | 3100 | 8620 | 381068 | 77168 | 234 | 320 | 400 | |

| 580 | 425 | 5 | 4 | 4580 | 11700 | 381168 | 1077768 | 441 | 280 | 360 | |

| 350 | 590 | 420 | 2 | 5 | 4700 | 9700 | 380670 | 77770 | 475 | 280 | 360 |

| 355 | 490 | 316 | 4 | 4 | 4520 | 12200 | 380671 | - | 115 | 320 | 400 |

| Boundary dimensions | Basic load ratings | Part number | Mass | Limiting speeds | |||||||

| mm | kN | Current | Original | kg | r/min | ||||||

| d | D | T | rmin | r1min | Cr | Cor | Grease | Oil | |||

| 360 | 480 | 310 | 4 | 3 | 2760 | 8300 | 382972 | 2077972 | 149 | 340 | 430 |

| 480 | 375 | 3 | 3 | 3010 | 7870 | 382972X2 | 77872 | 189 | 340 | 430 | |

| 520 | 370 | 4 | 4 | 5560 | 14600 | 380672 | - | 253 | 300 | 380 | |

| 540 | 325 | 5 | 4 | 3388 | 8840 | 381072 | 77172 | 248 | 300 | 380 | |

| 540 | 360 | 5 | 5 | 5070 | 12500 | 381072X2 | - | 274 | 300 | 380 | |

| 600 | 420 | 6 | 6 | 7900 | 14000 | 381172 | 1077772 | 388 | 280 | 360 | |

| 600 | 540 | 5 | 5 | 9970 | 24900 | 381172X2 | - | 620 | 240 | 360 | |

| 370 | 490 | 292 | 3 | 3 | 3800 | 11600 | 380674 | - | 149 | 340 | 430 |

| 380 | 520 | 400 | 4 | 3 | 5560 | 16100 | 380676 | - | 240 | 280 | 380 |

| 550 | 350 | 5 | 5 | 5250 | 13100 | 380676 | 77776 | 273 | 280 | 380 | |

| 560 | 325 | 5 | 4 | 3360 | 8840 | 381076 | 77176 | 281 | 280 | 380 | |

| 560 | 360 | 5 | 5 | 5730 | 14000 | 381076X2 | - | 294 | 280 | 360 | |

| 620 | 388 | 6 | 6 | 4200 | 9500 | 381176X2 | 3077776 | 443 | 240 | 360 | |

| 620 | 420 | 5 | 4 | 4710 | 12300 | 381176 | 1077776 | 519 | 240 | 360 | |

| 395 | 545 | 288.7 | 4 | 7.5 | 2610 | 7490 | 380679 | 77779 | 194 | 280 | 360 |

| 400 | 540 | 280 | 4 | 4 | 3100 | 8750 | 380680 | 77880 | 175 | 280 | 360 |

| 600 | 356 | 5 | 4 | 4160 | 10400 | 381080 | 77180 | 317 | 240 | 320 | |

| 420 | 620 | 356 | 5 | 4 | 4160 | 10400 | 381084 | 77184 | 358 | 220 | 300 |

| 700 | 480 | 6 | 5 | 6780 | 18500 | 381184 | 1077784 | 760 | 190 | 260 | |

| 760 | 500 | 7.5 | 7.5 | 9350 | 20300 | 380684 | 77884 | 1039 | 180 | 240 | |

| 440 | 620 | 454 | 6 | 6 | 3960 | 7880 | 380688 | 77888 | 440 | 200 | 280 |

| 650 | 355 | 6 | 6 | 4290 | 12390 | 380088 | 77788 | 385 | 200 | 280 | |

| 650 | 376 | 6 | 5 | 4330 | 13700 | 381088 | 77188 | 401 | 200 | 280 | |

| 460 | 620 | 310 | 4 | 3 | 3360 | 10200 | 381992 | 1077992 | 232 | 200 | 280 |

| 650 | 474 | 6 | 6 | 5292 | 11270 | 380692 | 77892 | 495 | 180 | 240 | |

| 680 | 410 | 6 | 5 | 5130 | 14200 | 381092 | 77192 | 476 | 180 | 240 | |

| 730 | 440 | 4 | 7.5 | 6500 | 15100 | 380692X3 | 77792 | 694 | 170 | 220 | |

| 475 | 660 | 450 | 5 | 5 | 7330 | 22400 | 380695 | 77795 | 457 | 170 | 220 |

| 480 | 650 | 338 | 5 | 4 | 2450 | 5400 | 381996 | 1077996 | 301 | 190 | 260 |

| 678 | 494 | 6 | 6 | 10600 | 31900 | 380696 | - | 578 | 170 | 220 | |

| 700 | 342 | 6 | 6 | 7050 | 17900 | 381096X2 | - | 447 | 170 | 220 | |

| 700 | 420 | 6 | 5 | 5780 | 16900 | 381096 | 77196 | 547 | 170 | 220 | |

| 790 | 510 | 7.5 | 7.5 | 11570 | 26900 | 381196X2 | - | 1017 | 120 | 160 | |

| 490 | 625 | 385 | 4 | 4 | 5070 | 17670 | 380698 | - | 282 | 170 | 220 |

| 500 | 720 | 420 | 6 | 5 | 6650 | 19400 | 3810/500 | 771/500 | 565 | 160 | 200 |

| 830 | 540 | 7.5 | 7.5 | 13230 | 33000 | 3811/500X2 | - | 1194 | 120 | 160 | |

| 508 | 762 | 420 | 6 | 6 | 9050 | 23900 | 3806/508 | - | 684 | 160 | 200 |

| 520 | 735 | 535 | 6 | 6 | 10580 | 33400 | 3806/520 | - | 721 | 160 | 200 |

| 530 | 780 | 450 | 6 | 5 | 7520 | 21500 | 3810/530 | 771/530 | 744 | 140 | 180 |

| 870 | 560 | 7.5 | 7.5 | 14400 | 36150 | 3811/530X2 | - | 1342 | 120 | 160 | |

| 870 | 590 | 7.5 | 6 | 9300 | 26100 | 3811/530 | 10777/530 | 1422 | 120 | 160 | |

| 880 | 544 | 7.5 | 7.5 | 10500 | 25600 | 3806/530 | 30777/530 | 1350 | 120 | 160 | |

| 540 | 690 | 400 | 5 | 5 | 4860 | 17300 | - | 779/540 | 375 | 160 | 200 |

| 560 | 730 | 410 | 4 | 6 | 5560 | 18900 | 3828/560X | - | 441 | 140 | 180 |

| Boundary dimensions | Basic load ratings | Part number | Mass | Limiting speeds | |||||||

| mm | kN | Current | Original | kg | r/min | ||||||

| d | D | T | rmin | r1min | Cr | Cor | Grease | Oil | |||

| 560 | 750 | 368 | 5 | 4 | 4370 | 13300 | 3819/560 | 10779/560 | 456 | 140 | 180 |

| 920 | 620 | 7.5 | 6 | 11200 | 26100 | 3811/560 | 10777/560 | 1635 | 100 | 140 | |

| 600 | 800 | 365 | 5 | 5 | 5000 | 17800 | - | 779/600 | 489 | 120 | 160 |

| 800 | 380 | 5 | 4 | 5500 | 18900 | 3819/600 | 10779/600 | 536 | 120 | 160 | |

| 855 | 620 | 6 | 6 | 14700 | 48100 | 3806/600 | - | 1155 | 100 | 140 | |

| 870 | 415 | 6 | 6 | 9790 | 27200 | 3810/600X2 | - | 831 | 100 | 140 | |

| 870 | 480 | 6 | 5 | 8370 | 25400 | 3810/600 | 771/600 | 995 | 100 | 140 | |

| 980 | 615 | 7.5 | 6 | 17600 | 45600 | 3811/600X2 | - | 1865 | 90 | 120 | |

| 980 | 650 | 7.5 | 6 | 12700 | 36700 | 3811/600 | 10777/600 | 1970 | 90 | 120 | |

| 625 | 815 | 480 | 5 | 5 | 10400 | 31700 | 3806/625 | 777/625 | 647 | 100 | 140 |

| 630 | 850 | 418 | 6 | 5 | 6440 | 19800 | 3819/630 | 10779/630 | 720 | 100 | 140 |

| 890 | 650 | 7.5 | 7.5 | 16970 | 53800 | 3806/630 | - | 1293 | 100 | 140 | |

| 920 | 515 | 7.5 | 6 | 9170 | 26800 | 3810/630 | 771/630 | 1158 | 95 | 130 | |

| 920 | 600 | 7.5 | 7.5 | 16500 | 48200 | 3810/630X2 | - | 1342 | 90 | 120 | |

| 1030 | 645 | 7.5 | 7.5 | 20270 | 53160 | 3811/630X2 | - | 2162 | 85 | 110 | |

| 1030 | 670 | 7.5 | 6 | 14400 | 39900 | 3811/630 | 10777/630 | 2170 | 85 | 110 | |

| 650 | 1030 | 560 | 7.5 | 12 | 11460 | 22050 | 3806/650 | 777/650 | 1769 | 85 | 110 |

| 660 | 1070 | 650 | 7.5 | 7.5 | 12600 | 26500 | 3806/660 | 777/660 | 2282 | 80 | 100 |

| 670 | 900 | 412 | 6 | 5 | 6940 | 22300 | 3819/670 | 10779/670 | 959 | 95 | 130 |

| 950 | 700 | 7.5 | 7.5 | 19800 | 61900 | 3806/670 | - | 1599 | 90 | 120 | |

| 980 | 475 | 7.5 | 7.5 | 13880 | 36500 | 3810/670X2 | - | 1224 | 90 | 120 | |

| 1090 | 690 | 7.5 | 7.5 | 22700 | 58800 | 3811/670X2 | - | 2566 | 75 | 95 | |

| 1090 | 710 | 7.5 | 6 | 15700 | 39900 | 3811/670 | 10777/670 | 2665 | 75 | 95 | |

| 710 | 1030 | 490 | 7.5 | 7.5 | 14500 | 40600 | 3810/710X2 | - | 1372 | 75 | 95 |

| 1030 | 555 | 7.5 | 6 | 11200 | 35800 | 3810/710 | 771/710 | 1568 | 75 | 95 | |

| 1150 | 710 | 9.5 | 8 | 24500 | 65000 | 3811/710X2 | - | 2931 | 48 | 80 | |

| 1150 | 750 | 9.5 | 8 | 15840 | 33960 | 3811/710 | 10777/710 | 3227 | 48 | 80 | |

| 730 | 1035 | 755 | 7.5 | 7.5 | 22500 | 73200 | 3806/730 | - | 2043 | 75 | 95 |

| 750 | 1090 | 515 | 7.5 | 6 | 16200 | 45600 | 3810/750X2 | - | 1619 | 70 | 90 |

| 1090 | 605 | 7.5 | 6 | 13100 | 42400 | 3810/750 | 771/750 | 1874 | 70 | 90 | |

| 1130 | 690 | 7.5 | 7.5 | 19000 | 51700 | 3806/750 | 777/750 | 2516 | 48 | 80 | |

| 1220 | 750 | 9.5 | 8 | 27430 | 7380 | 3811/750X2 | - | 3504 | 48 | 80 | |

| 1220 | 840 | 9.5 | 8 | 21900 | 68000 | 3811/750 | 10777/750 | 3994 | 48 | 80 | |

| 774 | 1130 | 690 | 4 | 7.5 | 16700 | 50100 | - | 777/774 | 2400 | 48 | 80 |

| 780 | 1220 | 840 | 9.5 | 8 | 28400 | 74000 | 3806/780 | 779/780 | 3659 | 48 | 80 |

| 800 | 1120 | 820 | 7.5 | 7.5 | 26200 | 86300 | 3806/800 | - | 2842 | - | - |

| 840 | 1170 | 840 | 7.5 | 7.5 | 26300 | 86400 | 3806/840 | - | 2840 | - | - |

| 850 | 1360 | 900 | 12 | 9.5 | 38900 | 140600 | 3811/850 | 10777/850 | 5168 | - | - |

| 950 | 1360 | 880 | 7.5 | 6 | 23300 | 83600 | 3820/950 | 20771/950 | 4087 | - | - |

| 1060 | 1500 | 1000 | 9.5 | 8 | 29100 | 105000 | 3820/1060 | 20771/1060 | 5698 | - | - |

| 1070 | 1400 | 889.762 | 4 | 12 | 27270 | 90000 | BT4B 328100 | - | 3730 | - | - |

| 1080 | 1450 | 950 | 5 | 12 | 30240 | 97200 | BT4B 331559 | - | 4450 | - | - |

| 1250 | 1550 | 890 | 5 | 12 | 27270 | 102600 | BT4B 328819 | - | 3820 | - | - |

| 1260 | 1640 | 1000 | 5 | 12 | 35190 | 128700 | BT4B 332124 | - | 5800 | - | - |

| 1300 | 1720 | 1040 | 5 | 12 | 38610 | 126000 | BT4B 331950 | - | 7000 | - | - |

| 1500 | 1900 | 1080 | 4 | 12 | 42120 | 153000 | BT4B 332078 | - | 7700 | - | - |

| 1580 | 1960 | 1080 | 5 | 12 | 41130 | 158400 | BT4B 331934 | - | 7800 | - | - |

YOU MAY LIKE

VIEW MORESingle Row Tapered Roller Bearing

VIEW MORESingle Row Tapered Roller Bearing VIEW MORESelf Aligning Tapered Roller Bearing

VIEW MORESelf Aligning Tapered Roller Bearing VIEW MOREAxial Radial Cylindrical Roller Bearings

VIEW MOREAxial Radial Cylindrical Roller Bearings VIEW MORELarge Cylindrical Roller Bearing

VIEW MORELarge Cylindrical Roller Bearing VIEW MORECylindrical Roller Bearing Inch Series

VIEW MORECylindrical Roller Bearing Inch Series VIEW MORERoller Thrust Bearing

VIEW MORERoller Thrust Bearing VIEW MORESingle Row Spherical Roller Bearing

VIEW MORESingle Row Spherical Roller Bearing VIEW MORETapered Rolling Bearing

VIEW MORETapered Rolling Bearing